Polyether-ether-ketone material and surface modification method thereof

A polyetheretherketone and modification technology, which is applied in the field of polyetheretherketone materials and surface modification thereof, can solve the problems of low grafting rate, cumbersome grafting reaction steps, weak bonding between bioactive coating and substrate, etc. , to achieve the effect of promoting osteoblast differentiation and improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] After the pure polyetheretherketone of 10mm×10mm×1mm is polished, it is ultrasonically cleaned with acetone and deionized water in sequence, each time for 30 minutes, after cleaning, it is dried in an oven at 80°C and stored properly. Firstly, plasma immersion ion implantation is performed on the polyetheretherketone substrate with argon gas as the ion source, and its specific process parameters are shown in Table 1 in Comparative Example 1; In the hydrogen peroxide aqueous solution with a mass fraction of 30%, soak for 24 hours and then ultrasonically clean with deionized water for 3 times, each time for 20 minutes. Dry the cleaned polyether ether ketone material (AH-PEEK) naturally and store it properly.

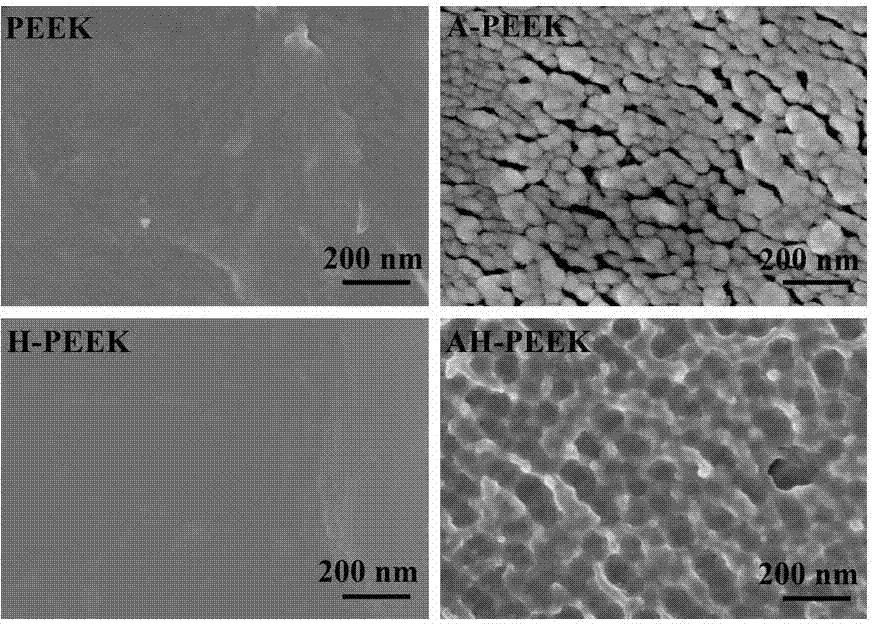

[0047] figure 1 (AH-PEEK) is the surface morphology diagram of the medical polyetheretherketone material obtained through the modification treatment of this example. The figure shows that there are shallow hole-like nanostructures on the surface of the modified mat...

Embodiment 2

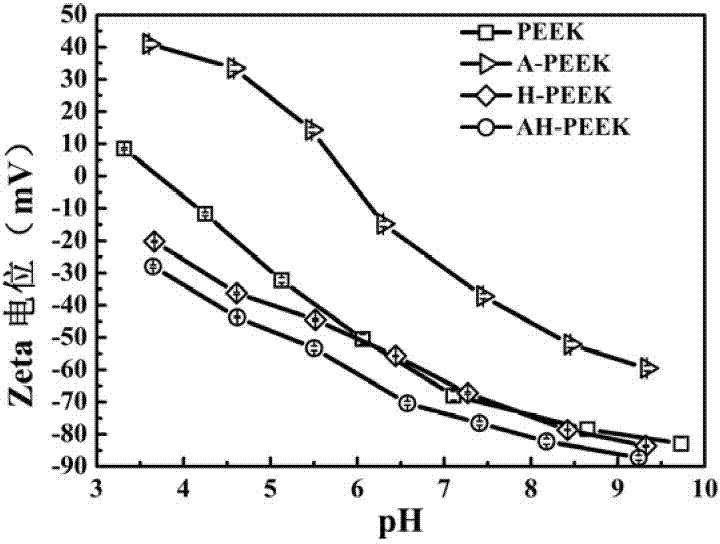

[0049] The electrical state near the surface of the polyether ether ketone material obtained through the modification treatment of the above Comparative Examples 1 and 2 and Example 1 was evaluated by using the Zeta potential test on the surface of the material. The specific method is as follows: Use an electrokinetic analyzer (Anton Paar, Austria) to measure the Zeta potential of the diffusion layer near the material surface as a function of the pH value of the electrolyte. Take two samples of 20mm×10mm×1mm for each group of materials to be tested, and install them face-to-face and parallel on the sample holder, leaving a certain gap between the two samples. The electrolytic solution used is 0.001M potassium chloride solution, and the pH value of the electrolytic solution is adjusted with hydrochloric acid and sodium hydroxide aqueous solution. At each different pH value point, the instrument will measure the electrokinetic current, pressure, electrolyte constant and sample s...

Embodiment 3

[0052] Rat bone marrow mesenchymal stem cells (BMSC) were cultured in vitro to evaluate the cytocompatibility of the polyetheretherketone material obtained through the modification of Comparative Examples 1 and 2 and Example 1 above. Using AlamarBlue (AlamarBlue TM , AbD serotec Ltd, UK) kit to detect the proliferation of cells on the material surface. Methods as below:

[0053] 1) Put the sample sterilized with 75% ethanol into a 24-well culture plate, add 1 mL to each well with a density of 2×10 4 cell / mLBMSC cell suspension;

[0054] 2) Put the cell culture plate into 5% CO 2 Incubate at 36.5°C for 18 hours in a cell culture incubator with saturated humidity;

[0055] 3) Aspirate the cell culture medium, wash the surface of the sample with PBS, transfer the sample to a new 24-well plate, and put it in the incubator to continue culturing;

[0056] 4) After the cells were cultured for 1, 4 and 7 days, the original culture solution was aspirated, and the cells containing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com