Dumbbell cobalt carbonate material and application thereof

A dumbbell-shaped, cobalt carbonate technology, applied in the direction of active material electrodes, structural parts, electrical components, etc., to achieve the effect of uniform size, good dispersion, simple and easy to control reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add cobalt chloride into distilled water in an amount of 0.1g / 40mL, and stir until the solution is clear;

[0030] (2) Add sodium tripolyphosphate in the amount of 0.1g / 40mL to the above solution, and then stir until the solution is clear;

[0031] (3) Add sodium carbonate to the solution described in step (2) with stirring in an amount of 0.2g / 40mL, and then continue to stir for 10min to obtain a cloudy solution;

[0032] (4) Transfer the solution prepared in step (3) to the reactor, seal it, put it in an oven at 100°C, and react for 8 hours;

[0033] (5) After the reaction is over, cool the reactor to room temperature;

[0034] (6) Discard the supernatant in the reaction kettle, rinse the product with water and ethanol for 3±1 times, and then dry it in a 50°C oven for 6 hours, and the obtained powdery product is a dumbbell-shaped cobalt carbonate material;

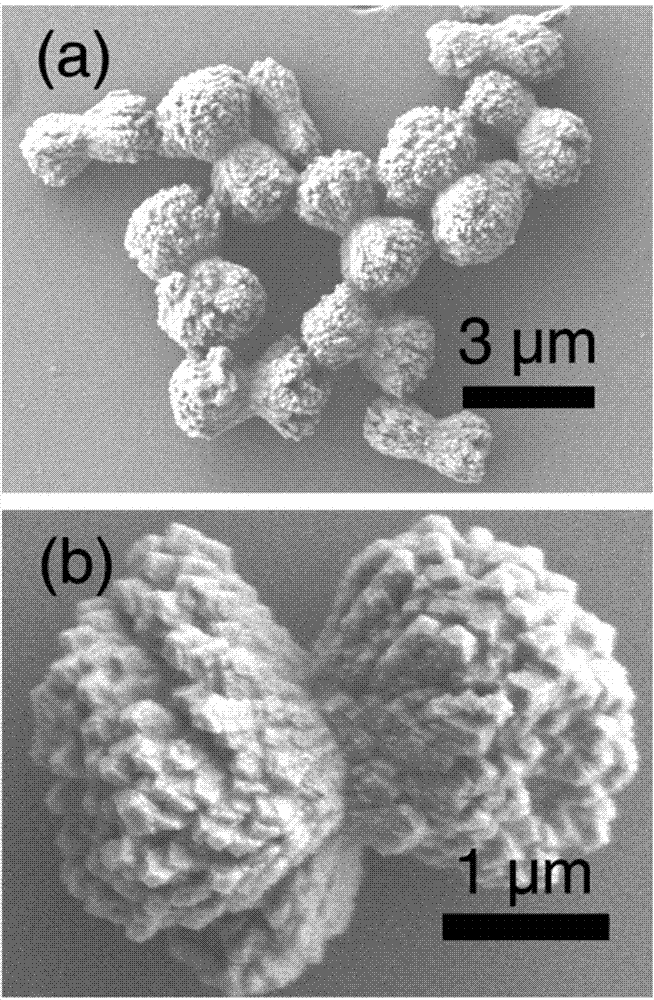

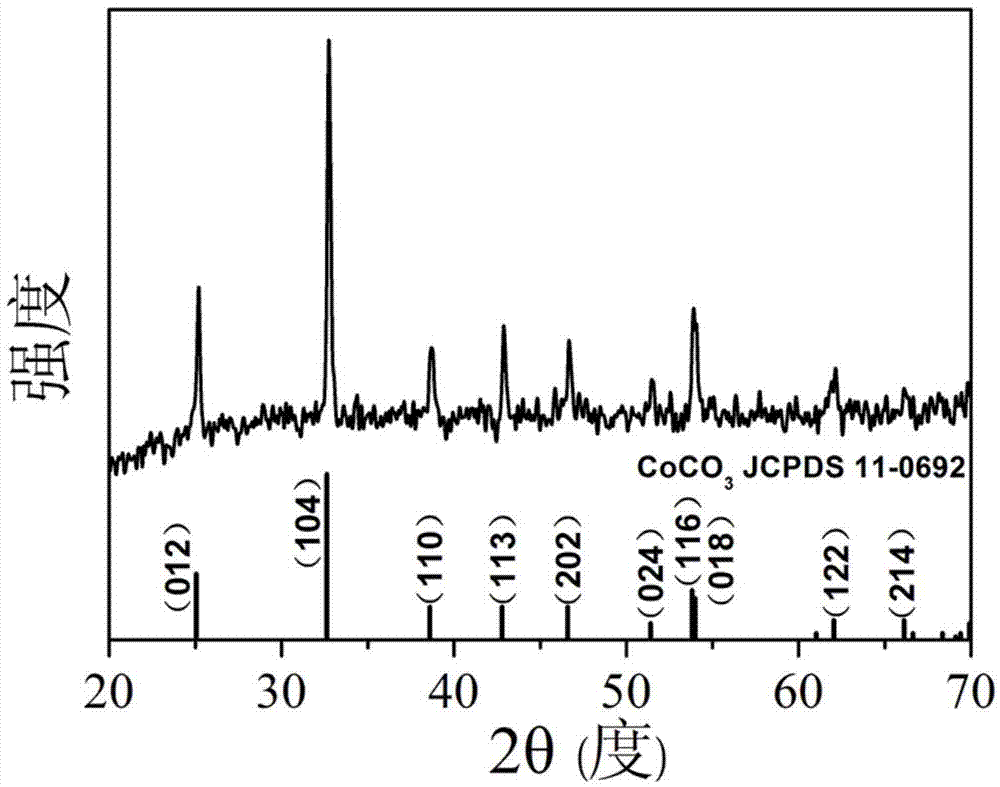

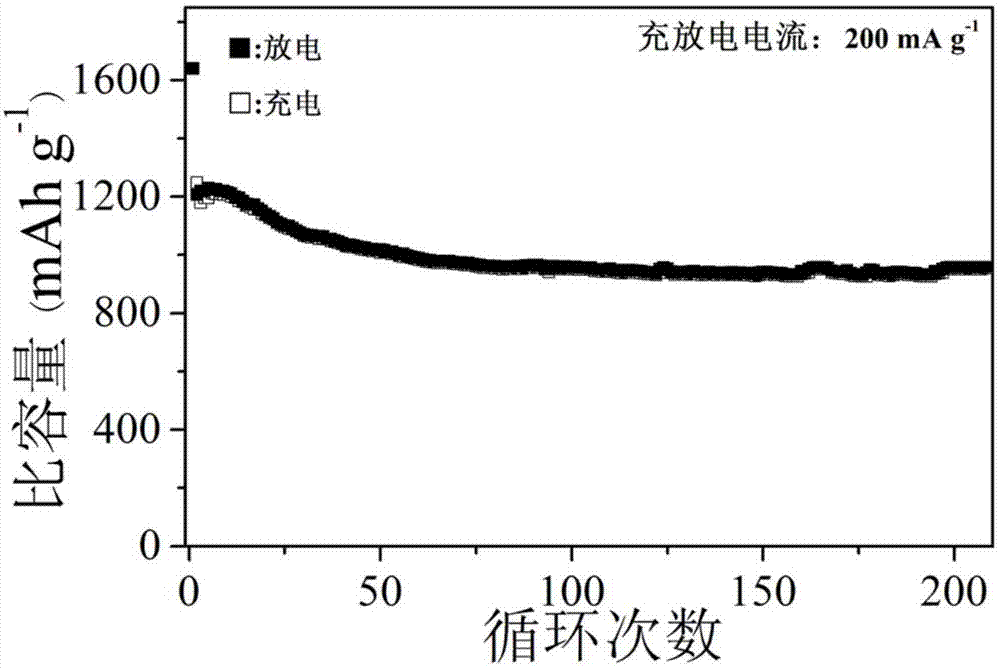

[0035] The shape of the product is as figure 1 As shown in the SEM photos, the crystallinity is as fig...

Embodiment 2

[0039] (1) Add cobalt nitrate into distilled water in an amount of 2g / 40mL, and stir until the solution is clear;

[0040] (2) Add triethanolamine to the above solution in an amount of 2g / 40mL, and stir until the solution is clear;

[0041] (3) Add potassium bicarbonate to the solution described in step (2) with stirring in an amount of 2g / 40mL, and then continue to stir for 15min to obtain a cloudy solution;

[0042] (4) Transfer the solution prepared in step (3) to the reactor, seal it, put it in an oven at 140°C, and react for 10 hours;

[0043] (5) After the reaction is over, cool the reactor to room temperature;

[0044] (6) Discard the supernatant in the reaction kettle, rinse the product with water and ethanol for 3±1 times, and then dry it in an oven at 70°C for 8 hours. The obtained powdery product is a dumbbell-shaped cobalt carbonate material;

[0045] The shape of the product is as figure 1 As shown in the SEM photos, the crystallinity is as figure 2 Shown in ...

Embodiment 3

[0049] (1) Add cobalt sulfate into distilled water in an amount of 4g / 40mL, and stir until the solution is clear;

[0050] (2) Add triethanolamine to the above solution in an amount of 4g / 40mL, and stir until the solution is clear;

[0051] (3) Add ammonium bicarbonate to the solution described in step (2) with stirring in an amount of 4g / 40mL, and then continue to stir for 20min to obtain a cloudy solution;

[0052] (4) Transfer the solution prepared in step (3) to the reactor, seal it, put it in an oven at 180°C, and react for 16 hours;

[0053] (5) After the reaction is over, cool the reactor to room temperature;

[0054] (6) Discard the supernatant in the reaction kettle, rinse the product with water and ethanol for 3±1 times, and then dry it in an oven at 80°C for 10 hours. The powdery product obtained is a dumbbell-shaped cobalt carbonate material;

[0055] The shape of the product is as figure 1 As shown in the SEM photos, the crystallinity is as figure 2 Shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com