Conductive adhesive composition, collector with adhesive layer, and electrochemical element electrode

An adhesive layer, conductivity technology, applied in conductive adhesives, non-aqueous electrolyte battery electrodes, electrical components and other directions, can solve the problems of high internal resistance, high electrolyte viscosity, high contact resistance, etc., to improve high temperature Effect of preservation characteristics, high temperature cycle characteristics and low temperature output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

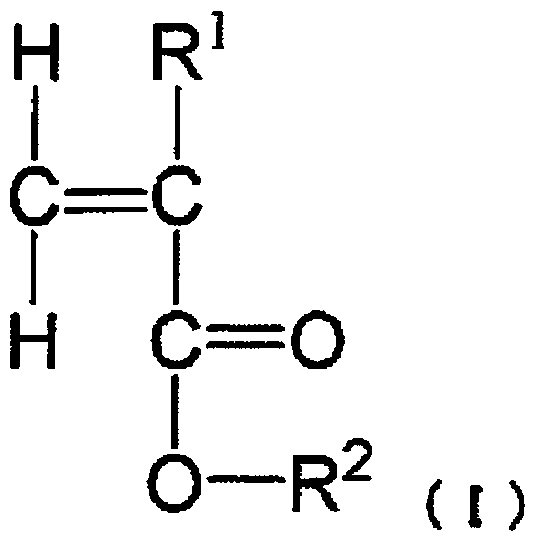

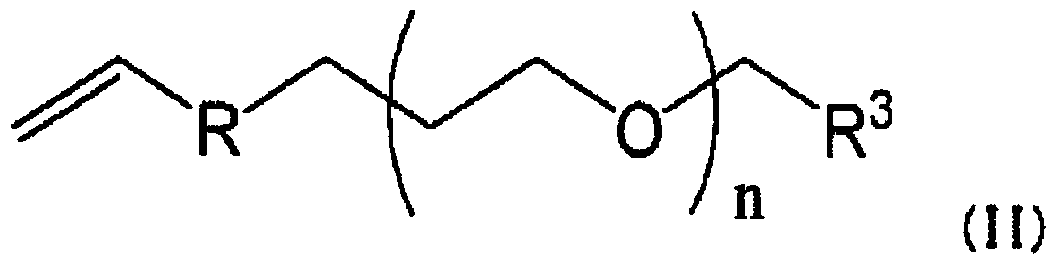

Method used

Image

Examples

Embodiment 1

[0210] (manufacturing of water-soluble polymers)

[0211] Put 59 parts of ethyl acrylate, 32.5 parts of methacrylic acid, 7.5 parts of 2,2,2-trifluoroethyl methacrylate, ethylene dimethacrylate (cross-linked monomer) 1 part, 1.5 parts of polyoxyalkylene alkenyl ether ammonium sulfate (Latemul PD-104, manufactured by Kao Corporation) as an emulsifier, 150 parts of ion-exchanged water, and 0.5 parts of potassium persulfate as a polymerization initiator After fully stirring, heat to 60°C to initiate polymerization. When the polymerization conversion rate was 96%, cooling was performed to stop the reaction, and an aqueous dispersion liquid containing a water-soluble polymer was obtained.

[0212] 10% ammonia water was added to the aqueous dispersion containing the above-mentioned water-soluble polymer to adjust the pH to 8 to obtain the desired aqueous solution of the water-soluble polymer. The viscosity of a 1% aqueous solution of the water-soluble polymer at pH 12 is 50 mPa·s....

Embodiment 2

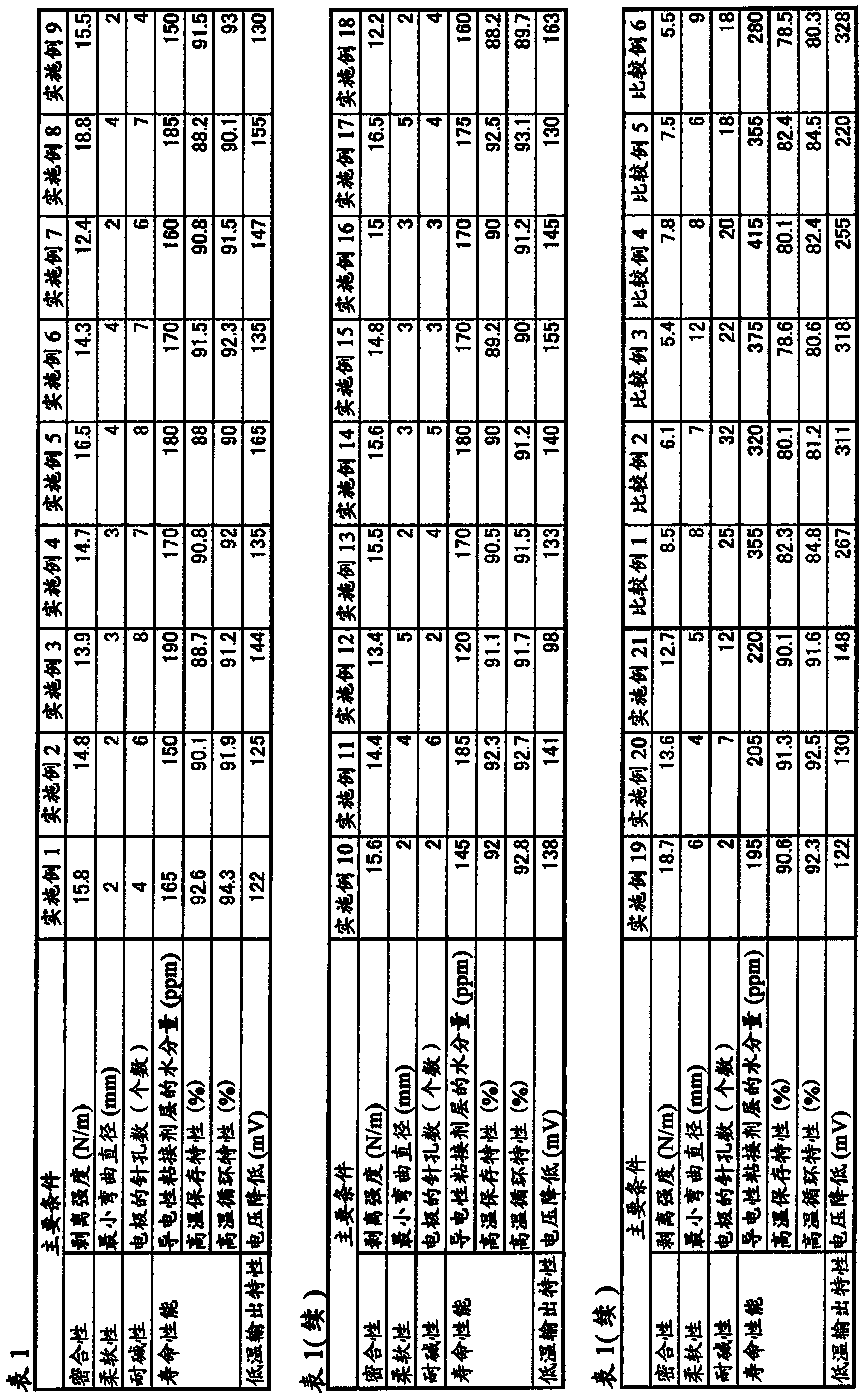

[0229] In Example 1 (manufacture of a conductive adhesive composition), it was the same as that of Example 1 except that only 100 parts of spherical graphite was used as a conductive carbon material. The results are shown in Table 1.

Embodiment 3

[0231] In Example 1 (manufacture of an electroconductive adhesive composition), it was the same as Example 1 except having used only 100 parts of carbon blacks as an electroconductive carbon material. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com