Method for preparing ordered mesoporous carbon material

A mesoporous carbon and mesoporous technology, which is used in the preparation of ordered mesoporous carbon materials and the field of ordered mesoporous carbon material preparation, can solve the problems affecting the order degree and specific surface area of mesoporous carbon materials, and hard template mesoporous channels. Filling up precursors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

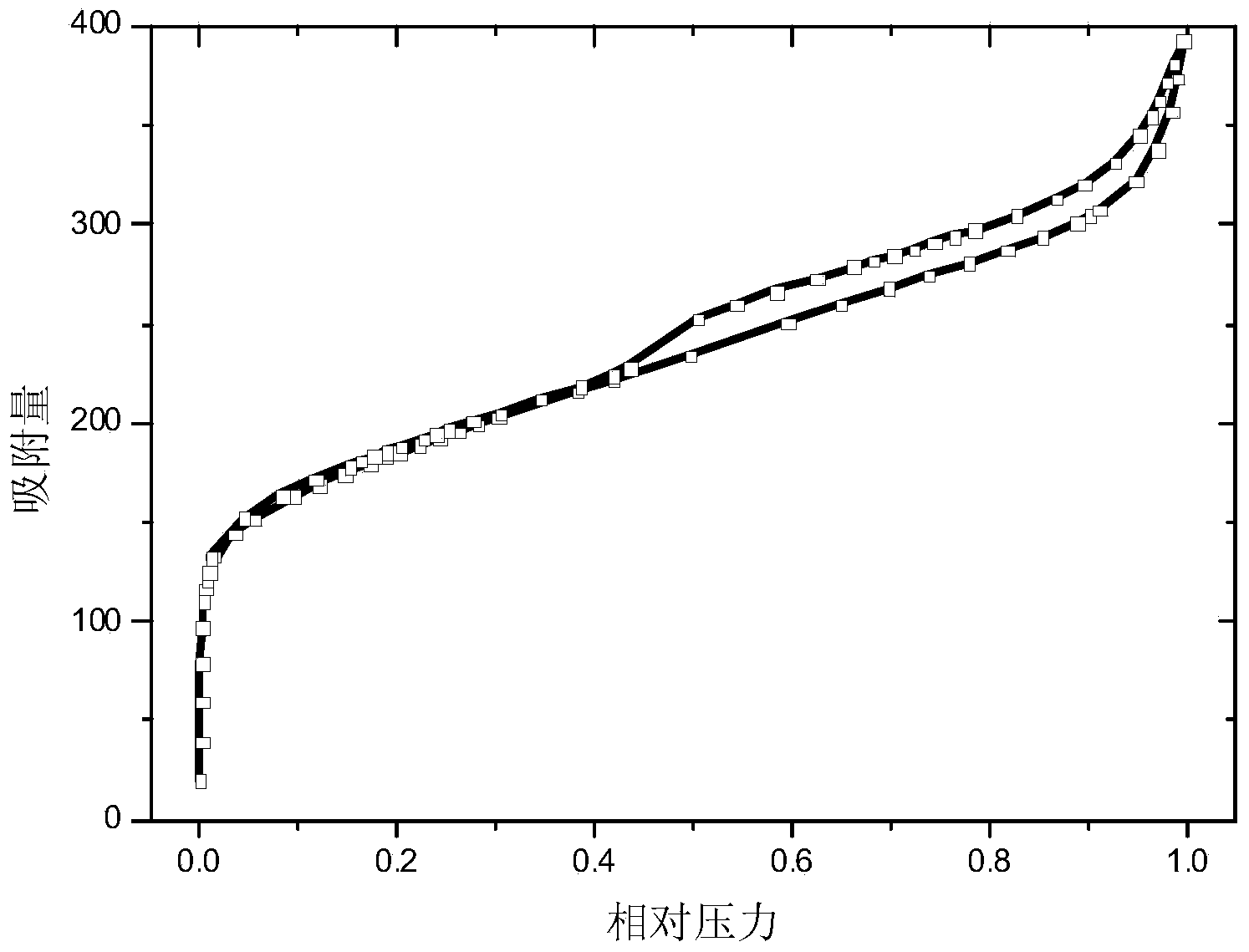

[0026] Weigh 4.0g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) into a 250ml beaker, add 126ml of deionized water, and stir at room temperature until P123 is completely dissolved. Add 20ml of concentrated hydrochloric acid with a mass fraction of 37% to the beaker, continue to stir for 2 hours, while the temperature of the water bath rises to 35°C, and then add 9.2ml of ethyl orthosilicate dropwise while stirring vigorously (rotation speed 200‐300rpm), continue After vigorous stirring for 24 hours, the reaction solution was poured into a self-pressurized reactor, crystallized at 100°C for 12 hours, suction filtered, washed, and dried at 80°C for 6 hours, and the dried sample was calcined at 550°C for 6 hours to remove the template agent to obtain SBA ‐15 molecular sieve, the nitrogen adsorption and desorption isotherm test shows that the nitrogen adsorption pore volume is 1.01cm 3 / g;

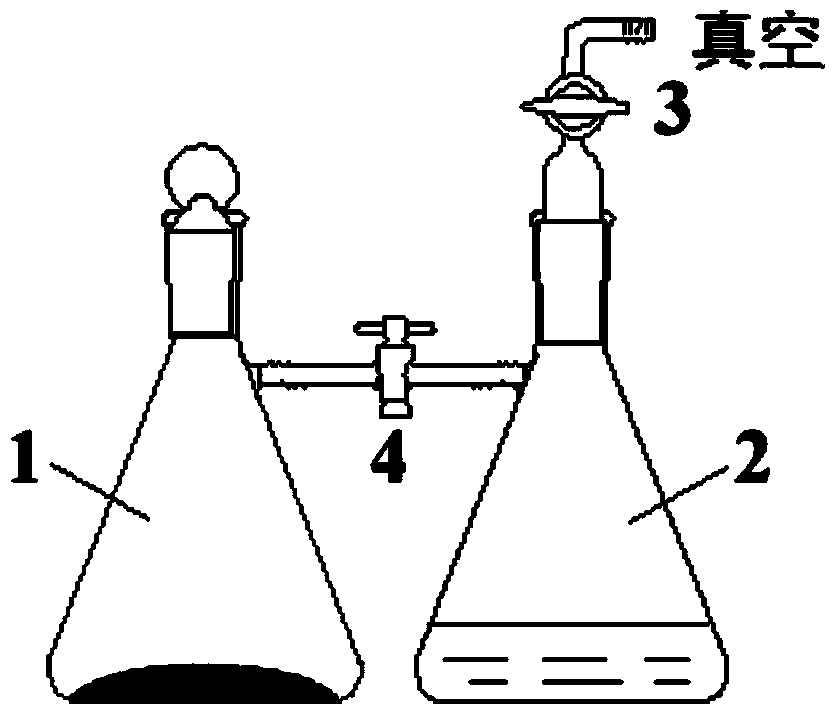

[0027] Take 1.0g SBA‐15 powder, add figure 1 In ...

Embodiment 2

[0030] Weigh 3.2g CTAB into a 250ml beaker, add 152ml deionized water and 24.0g NaOH, continue to stir for 2h, add 15.2g tetraethyl orthosilicate, stir for 1h, pour the solution into a self-pressurized reaction kettle, at 110°C Crystallize for 72 hours, filter and wash with water, dry at room temperature, and then bake at 550°C for 6 hours to remove the template agent to obtain MCM-48 molecular sieve;

[0031] Take 1.0g MCM-48 powder, add figure 1 In the left bottle 1 of the shown vacuum vaporization-capillary condensation nano-casting device, inject 1.01ml of aniline liquid into the right bottle 2, connect the second valve 4, and connect the first valve 3 after sealing to evacuate. Move the whole device into the heating box, raise the temperature from room temperature to 185°C, and keep the temperature until the liquid in the bottle 2 on the right disappears, then take it out after natural cooling, add 25ml of 0.5M ammonium persulfate solution to the bottle 1 on the left, and...

Embodiment 3

[0033] Weigh 4.0g of P123 into a 250ml beaker, add 126ml of deionized water, seal and stir at room temperature until P123 is completely dissolved, then add 20ml of concentrated hydrochloric acid with a mass fraction of 37% to the beaker, and continue stirring for 2 hours, while the temperature of the water bath rises to 40 ℃, then add 9.2ml tetraethyl orthosilicate dropwise while stirring vigorously, continue to stir vigorously for 24h, then pour the reaction solution into a self-pressurized reactor, crystallize at 120°C for 24h, wash with suction and wash with water at 80°C After drying for 4 hours, bake at 550°C for 6 hours to remove the template agent to obtain SBA-15 molecular sieve; take 1.0g of SBA-15 powder, add figure 1 In bottle 1 on the left as shown, inject 0.5ml of freshly steamed aniline and 0.5ml of freshly steamed pyrrole liquid into bottle 2 on the right, connect the second valve 4, connect the first valve 3 to vacuum after sealing, and then put the whole pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com