Molybdenum and carbon-codoped titanium oxide nanotube array thin film material and preparation method thereof

A technology of titanium oxide nanotubes and thin film materials, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that transition metal/non-metal co-doping cannot be realized and no transition is seen. Co-doped titanium oxide nanotube arrays with metal/non-metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

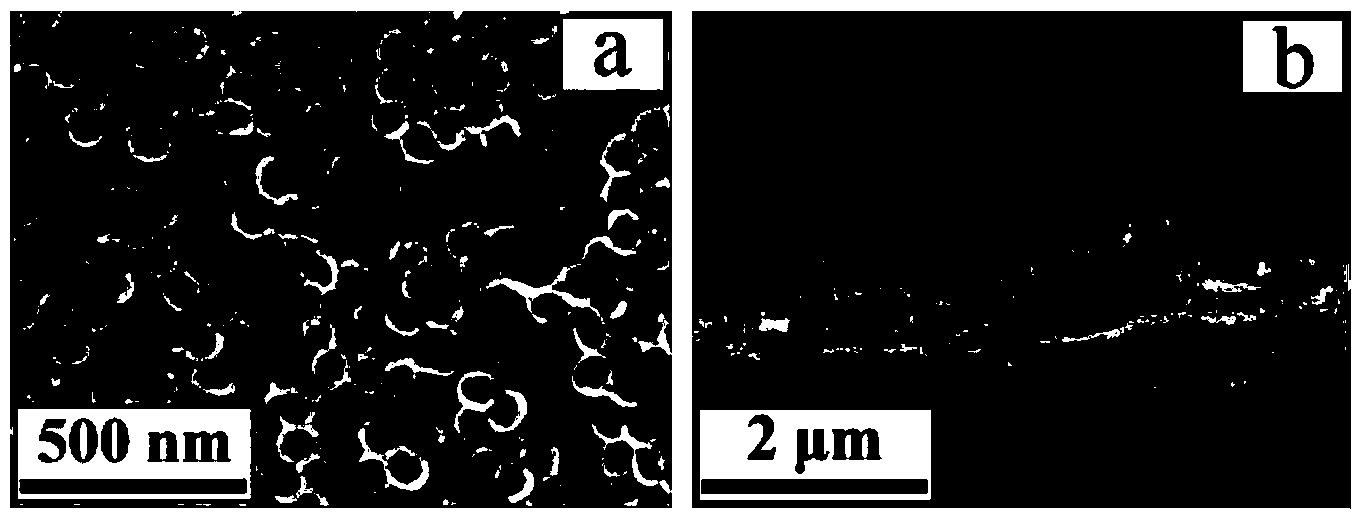

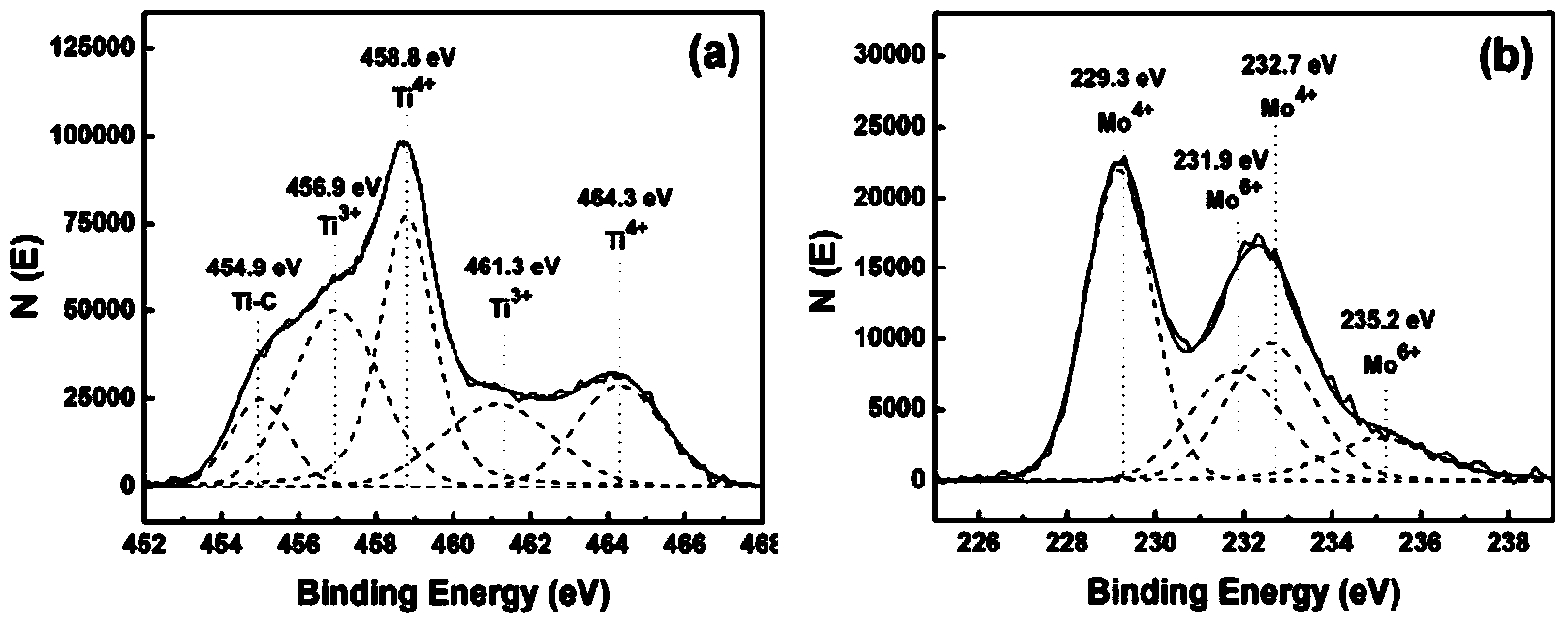

[0036] The Ti-5Mo alloy was heat-treated to obtain a single-phase structure, sliced, polished, and then anodized in an ethylene glycol solution with a mass fraction of ammonium fluoride of 0.3% and a volume fraction of water of 3% at a working voltage of 30V for 2h. A titanium oxide nanotube array film with a thickness of about 2.4 μm, a tube diameter of about 80 nm, and a molybdenum-titanium atomic ratio of 0.068 was obtained. The molybdenum-containing titanium oxide nanotube array film is heat-treated in air at 500° C. for 2 hours to obtain a molybdenum-doped titanium oxide nanotube array film. The molybdenum-doped titanium oxide nanotube array film was heat-treated at 550° C. for 3 hours in a carbon monoxide atmosphere to obtain a molybdenum-carbon co-doped titanium oxide nanotube array with a carbon-titanium atomic ratio of 0.08 (see figure 1 , 2 and Table 1).

[0037] Table 1 Composition analysis results of molybdenum-carbon co-doped titania nanotube arrays

[0038] ...

Embodiment 2

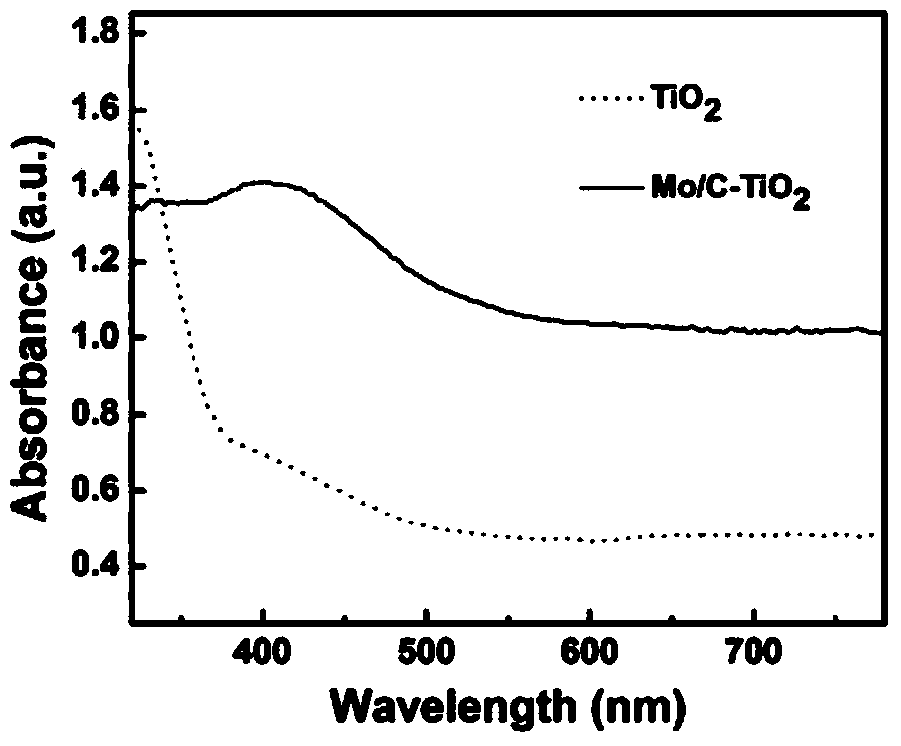

[0042] The absorption spectrum of molybdenum-carbon co-doped titanium oxide nanotube array film was measured by UV-vis2550 ultraviolet-visible spectrophotometer, and compared with the undoped titanium oxide nanotube array film of the same thickness. The results show that the visible light absorption ability of molybdenum carbon co-doped titania nanotube array film is much higher than that of undoped titania nanotube array film (see image 3 ).

Embodiment 3

[0044] With an intensity of 100mW / cm 2 The simulated sunlight was used as the light source, the 0.2M sodium sulfate solution was used as the electrolyte, and the molybdenum-carbon co-doped titanium oxide nanotube array film was used as the photoanode to investigate its photoelectrochemical performance under simulated sunlight. The results show that the photocurrent density of molybdenum carbon co-doped titania nanotube array film is 400mA / cm 2 , more than 2 times higher than that of the undoped sample (see Figure 4 a).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com