Synthetic method of escitalopram impurity J

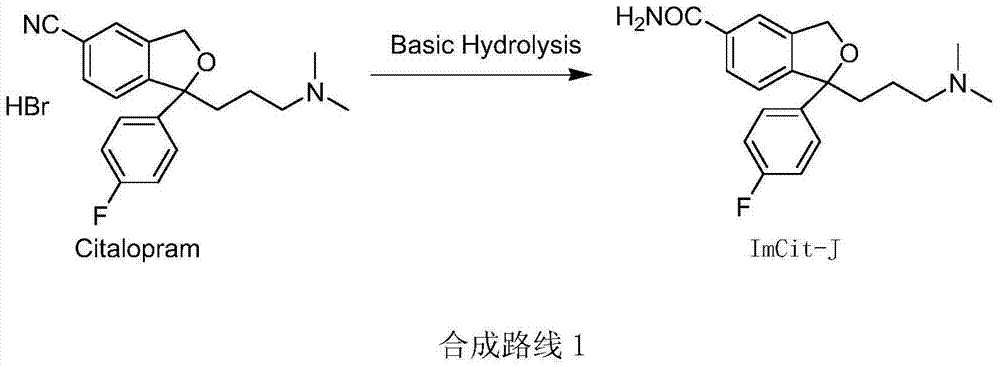

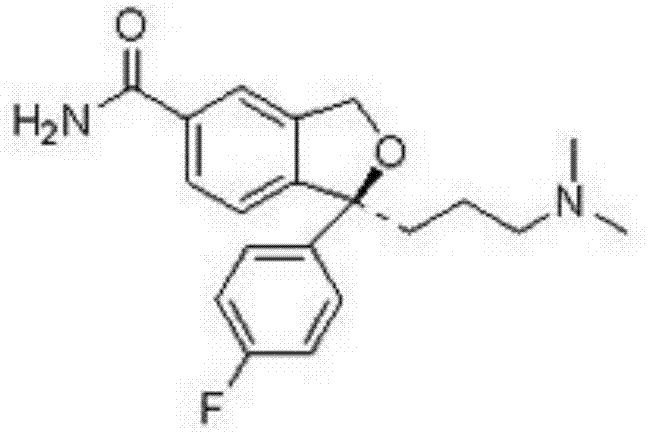

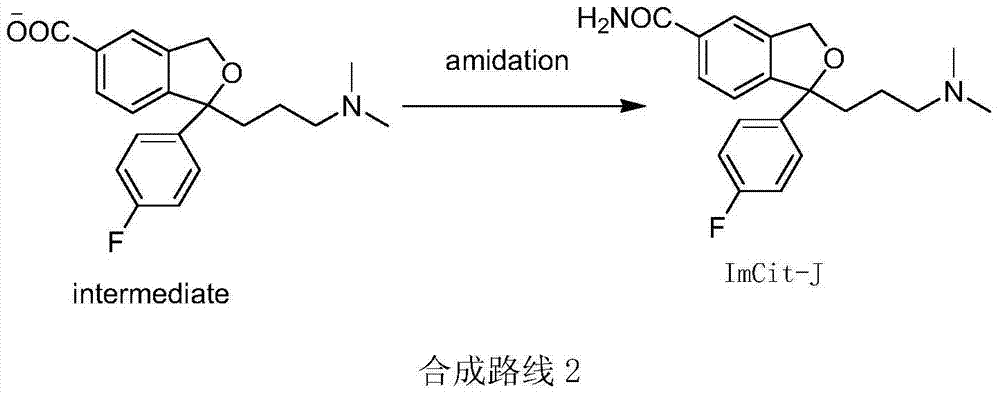

A synthesis method and technology of impurities, applied in the field of medicine, can solve the problems of high toxicity of reagents, low reaction yield, easy hydrolysis of cyano groups into acids, etc., and achieve the effects of less reagent and solvent pollution, simple synthesis route and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the synthetic method of escitalopram impurity J, specifically as follows:

[0026] Under nitrogen protection, escitalopram oxalate and potassium carbonate were suspended in tetrahydrofuran, hydrogen peroxide was added dropwise, and reacted at 20° C. for 6 hours. After the reaction is completed, a saturated sodium carbonate solution is added, the aqueous phase is extracted with ethyl acetate, the organic phase is dried over anhydrous sodium sulfate, and concentrated to obtain escitalopram impurity J, the escitalopram oxalate The weight ratio of hydrogen peroxide, potassium carbonate and tetrahydrofuran is 1:1:1:2, and the weight ratio of saturated sodium carbonate solution and ethyl acetate is 1:4.

Embodiment 2

[0027] Embodiment 2: the synthetic method of escitalopram impurity J, specifically as follows:

[0028] Under nitrogen protection, suspend escitalopram oxalate and potassium hydroxide in N,N-dimethylformamide, add hydrogen peroxide dropwise, and react at 60°C for 48h. After the reaction is completed, a saturated sodium carbonate solution is added, the aqueous phase is extracted with ethyl acetate, the organic phase is dried over anhydrous sodium sulfate, and concentrated to obtain escitalopram impurity J, the escitalopram oxalate , hydrogen peroxide, potassium hydroxide, and N,N-dimethylformamide in a weight ratio of 1:30:6:40, and a saturated sodium carbonate solution and ethyl acetate in a weight ratio of 1:20.

Embodiment 3

[0029] Embodiment 3: the synthetic method of escitalopram impurity J, specifically as follows:

[0030] Under nitrogen protection, escitalopram oxalate and triethylamine were suspended in dimethyl sulfoxide, hydrogen peroxide was added dropwise, and reacted at 25°C for 12 hours. After the reaction is completed, a saturated sodium carbonate solution is added, the aqueous phase is extracted with ethyl acetate, the organic phase is dried over anhydrous sodium sulfate, and concentrated to obtain escitalopram impurity J, the escitalopram oxalate The weight ratio of hydrogen peroxide, triethylamine and dimethyl sulfoxide is 1:10:3:15, and the weight ratio of saturated sodium carbonate solution and ethyl acetate is 1:15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com