N-semi aromatic hydrocarbyl bisphenol-diamine tetrafunctional fluorene-based benzoxazine and preparation method thereof

A semi-aromatic hydrocarbon-based bisphenol, tetrafunctional technology, applied in the direction of organic chemistry, etc., can solve the problems of unstable aliphatic amine-based oxazine ring, prone to ring-opening reaction, unable to obtain the target product, etc., and achieve the total product yield Improve, excellent thermal stability, the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

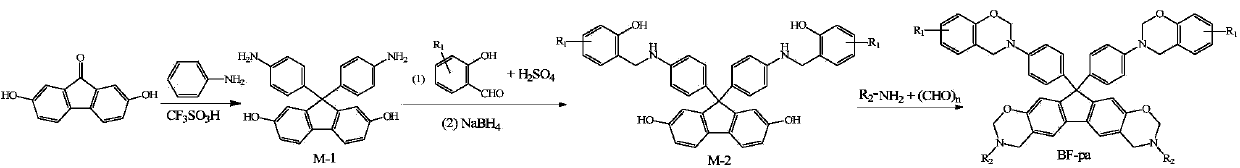

Method used

Image

Examples

Embodiment 1

[0028] (1) Synthesis of 2,7-dihydroxy-9,9-bis-(4-aminophenyl)fluorene

[0029] Add 0.05mol 2,7-dihydroxy-9-fluorenone, 0.40mol aniline and 0.015mol trifluoromethanesulfonic acid to a four-necked flask with a stirring rotor, a condenser tube, a thermometer and a gas inlet in sequence, and feed in nitrogen, React at 150°C for 10 h, then cool to room temperature, pour the product into 100 mL of 5 g / L sodium hydroxide ethanol solution, filter the precipitate, wash with ethanol, and dry in vacuum to obtain 2,7-dihydroxy-9,9 - Bis-(4-aminophenyl)fluorene (M-1), the yield is 92.3%.

[0030] (2) Synthesis of substituted or unsubstituted o-hydroxybenzylamino bisphenol fluorene

[0031] Add 0.02mol M-1, 0.04mol 2-hydroxybenzaldehyde, 0.004mol sulfuric acid and 150mL ethanol into a three-necked flask equipped with a stirrer, a condenser, and a thermometer, heat and reflux for 8 hours, cool to room temperature after the reaction, and add 0.06 mol sodium borohydride, then continue to sti...

Embodiment 2

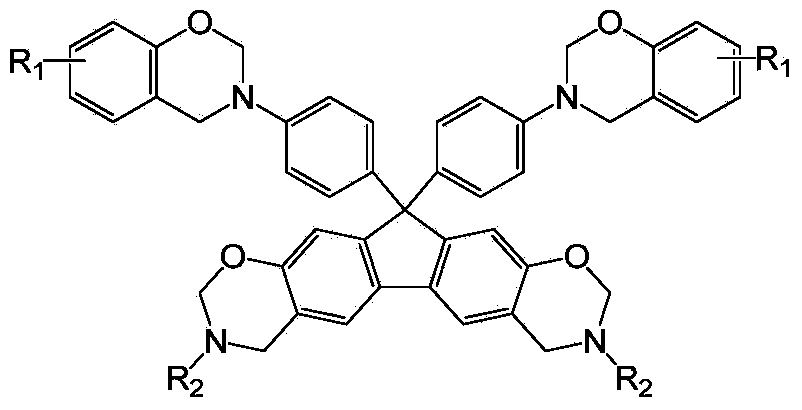

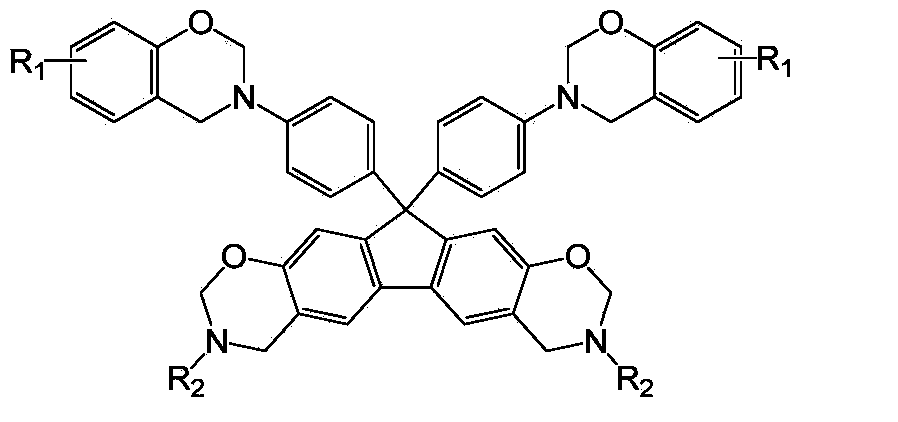

[0037] Except that the 2-hydroxybenzaldehyde in the synthesis step (2) was changed to 4-fluoro-2-hydroxybenzaldehyde, the reflux reaction time was changed from 8h to 6h, the butylamine in the synthesis step (3) was changed to octylamine, and the solvent was changed from 40mL dioxane and 10mL chlorobenzene are changed into 30mL toluene and 20mL chlorobenzene, and the reaction time is changed from 24h to 12h, other conditions are the same as in Example 1, and finally the N-semi Aromatic hydrocarbon-based bisphenol-diamine tetrafunctional fluorenyl benzoxazine monomer, T m The temperature is 68°C, and the yield is 69.3% (calculated based on the yields of synthesis steps 2 to 5, the same below).

[0038] 1 H NMR: 6.58~7.37 (m, 18H, Ar-H), 5.33 and 4.73 (d, 8H, O-CH on fluorene ring and benzene ring, respectively 2 -N), 4.55 and 3.94 (d, 8H, Ar-CH on the fluorene ring and benzene ring, respectively 2 -N), 2.68(t,4H,N-CH 2 -), 1.54 and 1.21 (m, 24H, -CH 2 -), 0.86(t,6H,-CH 3 )...

Embodiment 3

[0041] Except that the 2-hydroxybenzaldehyde in the synthesis step (2) is changed to 4-methoxy-2-hydroxybenzaldehyde, the butylamine in the synthesis step (3) is changed to cyclohexylamine, and the solvent consists of 40mL dioxane and 10mL of chlorobenzene was changed into 45mL of xylene and 5mL of chlorobenzene, the reaction temperature was changed from 110°C to 140°C, and the reaction time was changed from 24h to 12h, other conditions were the same as in Example 1, and finally 4-methoxy salicylaldehyde- N-semiaromatic hydrocarbon-based bisphenol-bisamine tetrafunctional fluorenyl benzoxazine monomer derived from cyclohexylamine, T m It was 112°C, and the yield was 77.8%.

[0042] 1 H NMR: 6.53~7.32 (m, 18H, Ar-H), 5.34 and 4.85 (d, 8H, O-CH on fluorene ring and benzene ring, respectively 2 -N), 4.56 and 4.05 (d, 8H, Ar-CH on the fluorene ring and benzene ring, respectively 2 -N), 3.45 (s, 6H, O-CH 3 ), 2.52 (m, 2H, N-CH-), 1.05~1.86 (m, 20H, -CH2 -); FT-IR: 1505, 1387, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com