A method for preparing low-silicon vanadium pentoxide from vanadium-chromium-silicon solution

A silicon solution, vanadium-chromium technology, applied in the field of preparing low-silicon V2O5 and preparing low-silicon and high-purity V2O5, can solve the problems of vanadate reaching 99.5%, unfavorable popularization and application, repeated and complicated operations, etc., and achieves clear oil-water interface and removal of Good efficiency and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

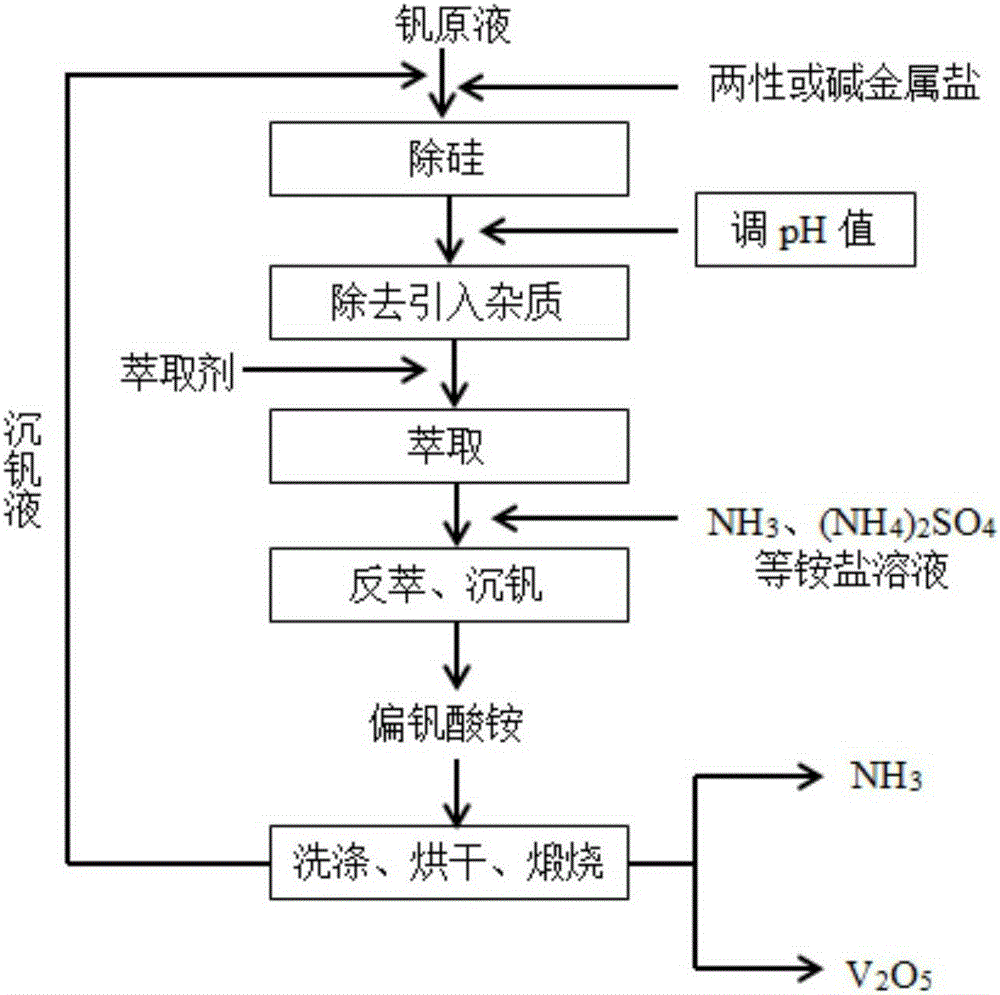

Method used

Image

Examples

Embodiment 1

[0049] A kind of preparation high-purity V from vanadium-chromium-silicon solution 2 o 5 method, including the following steps:

[0050] 1) Put 250ml of a solution containing pentavalent vanadium and hexavalent chromium in a beaker, heat it with a water bath to 90°C and add 5.86g of AlCl 3 , 1.547gCaO, stirring the reaction for 30min with a stirring paddle, cooling to room temperature and adjusting the pH value to 8.8 with sulfuric acid, stirring for another 5 minutes, and centrifuging to separate the solid and liquid;

[0051] 2) Adjust the collected silicon removal solution to 4.2 with sulfuric acid, then mix it with primary amine extractant (containing 10% JMT, 5% hexyl acetate and 85% kerosene) at a ratio of 1:1, and stir at 30°C 5min, stand until the oil and water are completely separated;

[0052] 3) Add sulfuric acid to the raffinate (water phase) to adjust the pH value to 3, then add 1 times the theoretical amount of anhydrous sodium sulfite to the solution, adjust ...

Embodiment 2

[0057] A kind of preparation high-purity V from vanadium-chromium-silicon solution 2 o 5 method, including the following steps:

[0058] 1) Put 500ml of a solution containing pentavalent vanadium and hexavalent chromium in a beaker, heat it with a water bath to 60°C and add 5.86g of Al 2 (SO 4 ) 3 and 0.751g CaCl 2 , after stirring and reacting with a stirring paddle for 40 minutes, cool to room temperature and adjust the pH value to 7.7 with sulfuric acid, and then stir for 10 minutes, then centrifuge to separate the solid and liquid;

[0059] 2) Adjust the collected desiliconization solution to 3.6 with sulfuric acid, and then mix it with primary amine extractant (containing 15% JMT, 5% ethyl p-methylparaformate and 80% kerosene) in a ratio of 2:1, at 25 Stir at ℃ for 20 minutes, and let it stand until the oil and water are completely separated;

[0060] 3) Add sulfuric acid to the raffinate (water phase) to adjust the pH to 3.4, then add 1.03 times the theoretical amo...

Embodiment 3

[0065] A kind of preparation high-purity V from vanadium-chromium-silicon solution 2 o 5 method, including the following steps:

[0066] 1) Put 1000ml of solution containing pentavalent vanadium and hexavalent chromium in a beaker, heat it with a water bath to 70°C and add 1.056g of Al(OH) 3 and 0.7gCaCl 2 , after stirring and reacting with a stirring paddle for 50 minutes, cool to room temperature and adjust the pH value to 8.0 with sulfuric acid, stir for another 10 minutes, and centrifuge to separate the solid and liquid;

[0067] 2) Adjust the collected desiliconization solution to 3.4 with sulfuric acid, and then mix it with primary amine extractant (containing 15% N1923, 6% ethyl p-methylbenzoate and 79% kerosene) in a ratio of 3:1, at 20 Stir at ℃ for 30 minutes, and let it stand until the oil and water are completely separated;

[0068] 3) Add sulfuric acid to the raffinate (water phase) to adjust the pH value to 2.5, then add 1.2 times the theoretical amount of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com