Atom gas cavity device with double reflectors and groove-shaped structure and manufacturing method thereof

A technology of atomic gas cavity and double mirror, applied in the direction of microstructure devices without moving elements, chemical instruments and methods, instruments using atomic clocks, etc., can solve the problems of low signal-to-noise ratio, difficulty, and cost of CPT signals, Achieve the effects of enhanced signal-to-noise ratio, improved stability, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

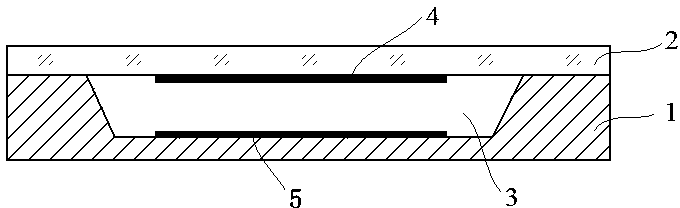

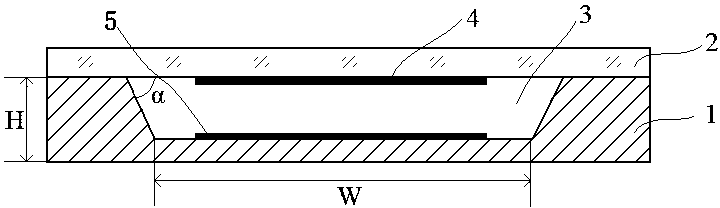

[0030] see figure 1 and figure 2 , an atomic gas cavity device with double mirrors and a groove-shaped structure includes a silicon wafer 1 and a glass wafer 2 . One side of the silicon chip 1 is provided with a groove, the cross section of the groove is an inverted trapezoid, and the inner bottom of the groove is provided with a lower reflector 5; one side of the glass sheet 2 is provided with an upper reflector 4; the silicon chip 1 and the glass sheet 2 The atomic gas cavity is formed by bonding 3 The device, the upper mirror 4 on the glass sheet 2 is correspondingly located in the groove of the silicon wafer 1, and corresponds to the lower mirror 5.

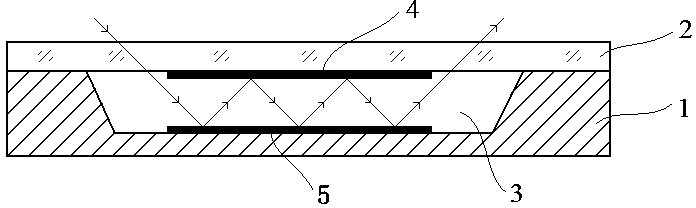

[0031] like image 3 As shown, the optical path of the laser in the atomic gas cavity 3 device is mainly determined by the width W of the bottom of the groove, and the optical path can be changed by adjusting the size of W. see Figure 4 , in the traditional atomic gas cavity device, the laser is directly injected from t...

Embodiment 2

[0039] The structure of the atomic gas cavity of the present embodiment is as follows figure 1 As shown, the specific implementation scheme is as follows:

[0040] 1. Select a P(100) silicon wafer 1 with a thickness of 0.5-1 mm, use silicon nitride as a mask, and perform anisotropic wet etching through TMAH solution to form an inverted trapezoidal cross section on the silicon wafer 1. One hundred and fifty grooves, the side walls of the grooves are {111} crystal planes, and the lateral width of the through holes is 5 mm. The corrosion temperature of TMAH solution is 80°C;

[0041] 2. Using the sputtering process and hard mask technology, one hundred and fifty metal film mirrors, namely the upper mirror 4, are fabricated on one side of the glass sheet 2; at the bottom of each groove of the silicon wafer 1 Make one hundred and fifty metal film reflectors, that is, the lower reflector 5;

[0042] 3. Carry out silicon-glass bonding, and feed cesium vapor and buffer gas at the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com