A kind of preparation method of antioxidant-coated polymer nanovesicles

An antioxidant and nano-vesicle technology, applied in the field of skin beauty and health care chemicals, can solve the problems of no way to eliminate free radicals, no skin, harmful to human body, etc., achieve high-efficiency anti-ultraviolet performance, delay skin aging, and stable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

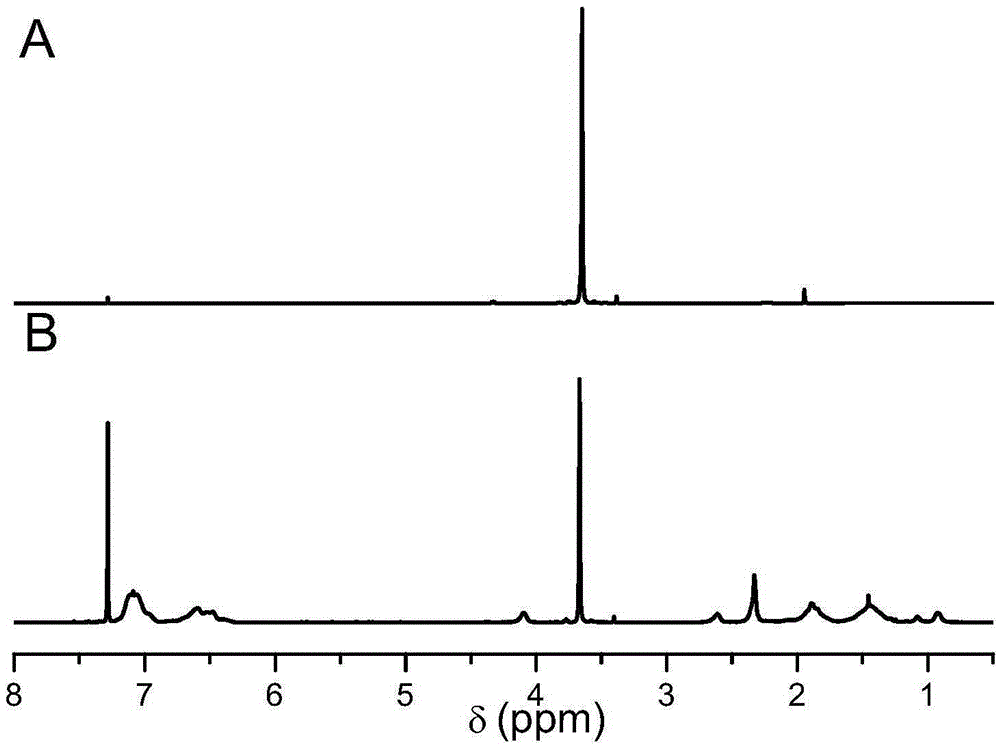

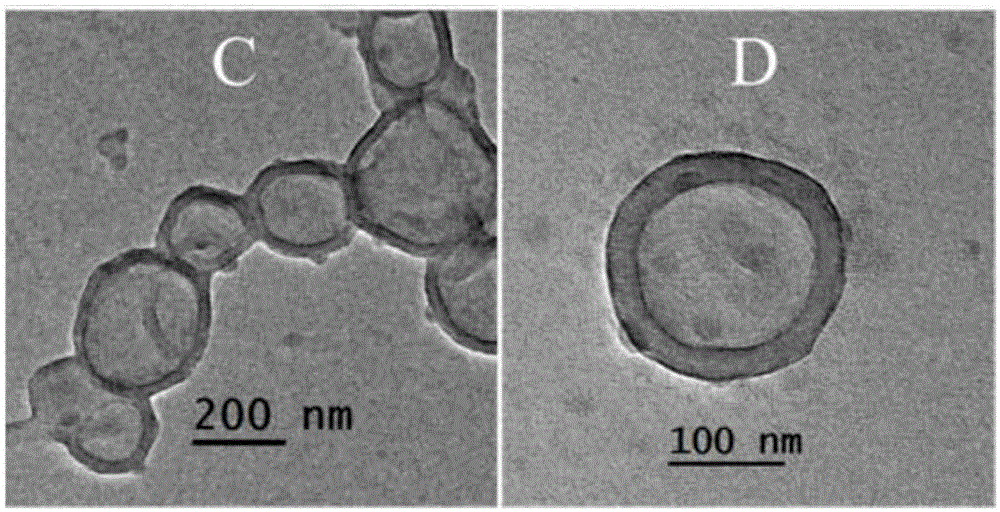

Embodiment 1

[0029] 0.5g macroinitiator PEO 43 -Br, 0.08g of catalyst ligand PMDETA, 0.8g of monomer DMA and 2ml of anhydrous methanol were added to the round bottom flask, macroinitiator PEO 43 The molar ratio of -Br, catalyst ligand PMDETA and monomer DMA is 1:1:20; Add 0.08g catalyst CuBr under the condition of anhydrous and oxygen-free; 43 The number of moles of -Br is the same. Atom transfer radical polymerization (ATRP) was carried out under the protection of argon or nitrogen, the reaction temperature was 25°C, and the reaction time was 8 hours. After the reaction, 3.9 g of monomeric styrene was dissolved in 10 ml of p-xylene, and added to the flask after deoxygenation. The reaction temperature was 60° C., and the reaction time was 50 hours. The prepared polymer is rotary evaporated, dissolved, passed through a neutral alumina column, precipitated, filtered, and vacuum-dried to obtain the amphiphilic block copolymer PEO 43 -b-PDMA 20 -b-PS 110 ; Wherein the mol ratio of styrene...

Embodiment 2

[0031] 0.5g macroinitiator PEO 43 -Br, 0.24g catalyst ligand PMDETA, 2.4g monomer DMA and 2ml anhydrous methanol were added to the round bottom flask, macroinitiator PEO 43 The molar ratio of -Br, catalyst ligand PMDETA and monomer DMA is 1:3:60; Add 0.08g catalyst CuBr under the condition of anhydrous and oxygen-free; 43 The number of moles of -Br is the same. Atom transfer radical polymerization (ATRP) was carried out under the protection of argon or nitrogen, the reaction temperature was 40°C, and the reaction time was 13 hours. After the reaction, 7.8 g of monomeric styrene was dissolved in 10 ml of p-xylene, and added to the flask after deoxygenation. The reaction temperature was 80° C., and the reaction time was 60 hours. The prepared polymer is rotary evaporated, dissolved, passed through a neutral alumina column, precipitated, filtered, and vacuum-dried to obtain the amphiphilic block copolymer PEO 43 -b-PDMA 60 -b-PS 220 ; Wherein the mol ratio of styrene and bro...

Embodiment 3

[0034] 0.5g macroinitiator PEO 43 -Br, 0.4g catalyst ligand PMDETA, 3.2g monomer DMA and 3ml anhydrous methanol were added to the round bottom flask, macroinitiator PEO 43 The molar ratio of -Br, catalyst ligand PMDETA and monomer DMA is 1:4:80; Add 0.08g catalyst CuBr under the condition of anhydrous and oxygen-free; 43 The number of moles of -Br is the same. Atom transfer radical polymerization (ATRP) was carried out under the protection of argon or nitrogen, the reaction temperature was 50°C, and the reaction time was 18 hours. After the reaction, 11.7 g of monomeric styrene was dissolved in 15 ml of p-xylene, and added to the flask after deoxygenation. The reaction temperature was 130° C., and the reaction time was 12 hours. The prepared polymer is rotary evaporated, dissolved, passed through a neutral alumina column, precipitated, filtered, and vacuum-dried to obtain the amphiphilic block copolymer PEO 43 -b-PDMA 80 -b-PS 340 ; Wherein the mol ratio of styrene and br...

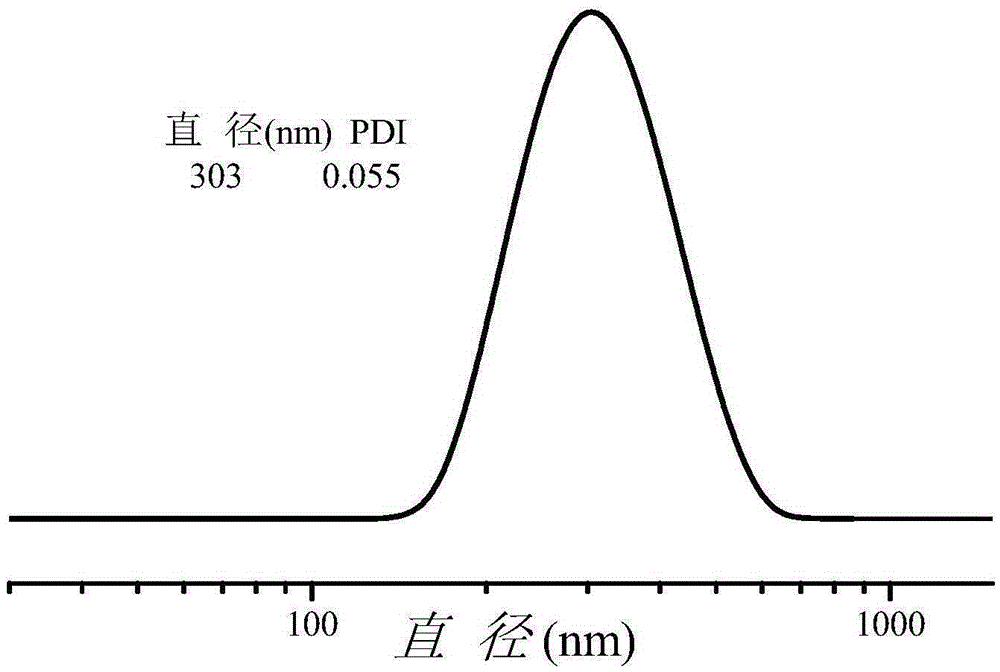

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com