Treatment method of edta cleaning waste liquid and its corresponding reaction device

A treatment method and technology of a reaction device, which are applied in the fields of cyanide reaction preparation, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of poor treatment effect, long treatment time and high treatment cost, and reduce the Difficulty in degradation, simple operation, and the effect of reducing cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

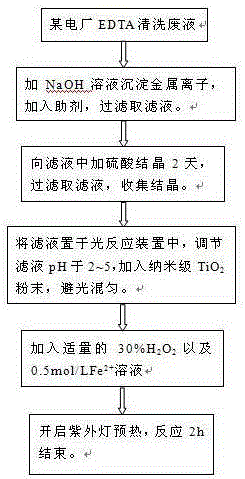

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

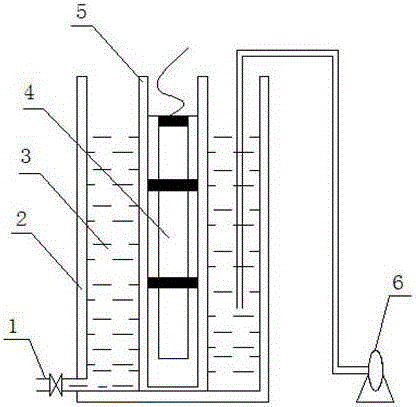

[0024] The main body of the photoreaction device is made of plexiglass, and the outer ring wall and lower bottom are made of plexiglass. In order to improve the absorption rate of ultraviolet light, the reaction device is designed as a cylinder with an outer diameter of 160mm, an inner diameter of 150mm, and a height of 500mm. A sleeve 5 with an outer diameter of 120mm is installed with an ultraviolet lamp 4. In order to ensure the effective passage of ultraviolet light, the sleeve is made of quartz. The effective volume of the device is 2L. In addition, the device is also designed with an auxiliary aeration device 6, and the effect of oxygen aeration is the best. Considering the economic cost, air aeration is generally used. The aeration device can bring out degradation products, increase the reaction rate, and shorten the degradation time. Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com