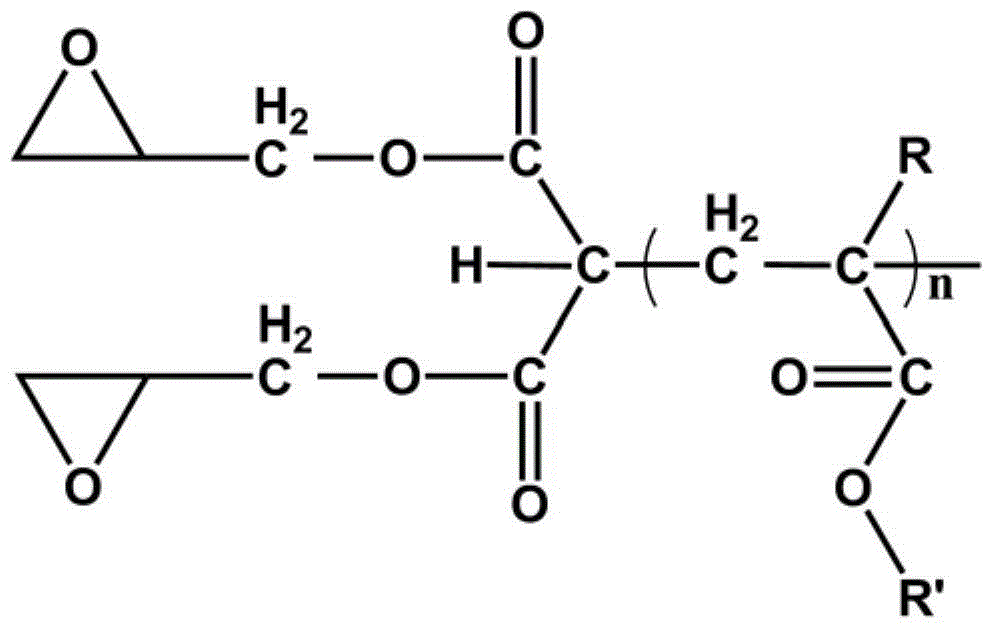

Long-side-chain fluorine-containing acrylic epoxy resin and coating prepared from resin as raw material

An acrylic epoxy resin, epoxy resin technology, applied in epoxy resin coatings, coatings, organic chemistry and other directions, can solve the problems of poor weather resistance, high surface energy, high water absorption, achieve good hydrophobic effect, improve stain resistance and weather resistance, the effect of reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

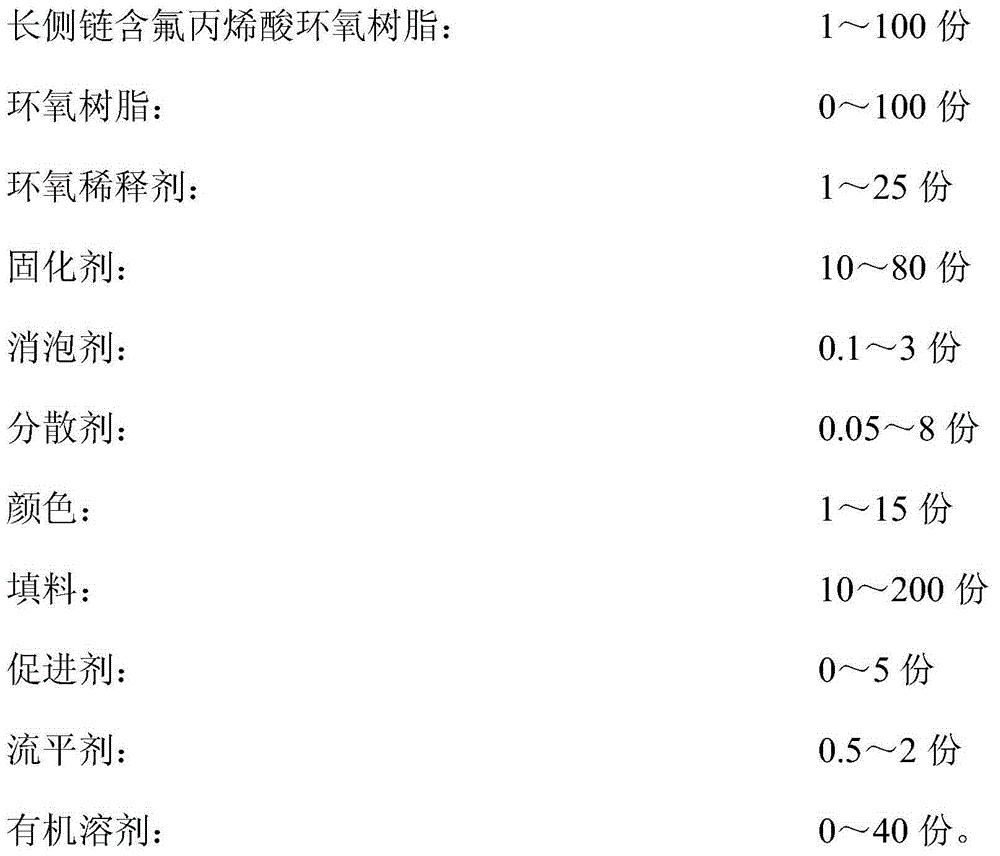

Method used

Image

Examples

Embodiment 1

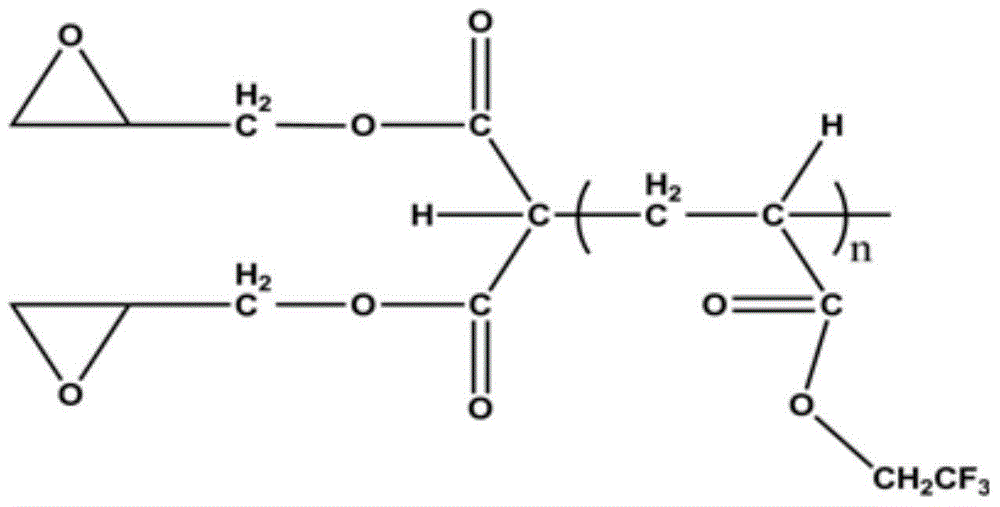

[0037] (1) Preparation of fluorine-containing acrylic acid long-chain polymers containing carboxyl-terminated: in parts by weight, mix 0.1 parts of dibutyl malonate, 50 parts of toluene and 0.5 parts of 25% by mass tetrabutylammonium hydroxide aqueous solution Evenly, react at 30°C for 5 hours, remove toluene under reduced pressure; then add 90 parts of tetrahydrofuran and 5 parts of trifluoroethyl acrylate monomer, mix uniformly and react for 0.1 hour, remove tetrahydrofuran under reduced pressure, and prepare the obtained product at 20 °C in a mixed solution (30 parts by mass of trifluoroacetic acid and 60 parts by mass of dioxane) for 4.5 hours to obtain a long-chain fluorine-containing acrylic acid polymer containing a carboxyl-terminated group.

[0038] (2) Preparation of long side chain fluorine-containing acrylic acid epoxy resin: in parts by weight, add 2 parts of fluorine-containing acrylic acid long-chain polymer containing carboxyl-terminated prepared in step (1) to ...

Embodiment 2

[0043](1) Preparation of fluorine-containing acrylic acid long-chain polymers containing terminal carboxyl groups: 2 mass parts of dibutyl malonate, 200 mass parts of toluene and 15 mass parts of tetrabutylammonium hydroxide aqueous solution with a concentration of 25% by mass were mixed evenly, React at 50°C for 7 hours, remove toluene under reduced pressure, then add 55 parts by mass of tetrahydrofuran and 50 parts by mass of dodecafluoroheptyl methacrylate monomer, mix uniformly and react for 2.5 hours, remove tetrahydrofuran under reduced pressure, and obtain The product was hydrolyzed in a mixed solution (27 parts by mass of trifluoroacetic acid and 40 parts by mass of dioxane) at 68°C for 6 hours to obtain a long-chain fluorine-containing acrylic acid polymer containing terminal carboxyl groups.

[0044] (2) Preparation of long side chain fluorine-containing acrylic epoxy resin: add 30 mass parts of fluorine-containing acrylic long-chain polymers containing carboxyl group...

Embodiment 3

[0049] (1) Preparation of fluorine-containing acrylic acid long-chain polymers containing terminal carboxyl groups: 0.6 parts by mass of dibutyl malonate, 80 parts by mass of toluene and 10 parts by mass of tetrabutylammonium hydroxide aqueous solution with a concentration of 25% by mass were mixed evenly, React at 40°C for 10 hours, remove the toluene under reduced pressure, then add 80 parts by mass of tetrahydrofuran and 10 parts by mass of trifluoroethyl methacrylate monomer, mix uniformly and react for 2 hours, remove the tetrahydrofuran under reduced pressure, and place the obtained product in Hydrolysis in a mixed solution (10 parts by mass of trifluoroacetic acid and 30 parts by mass of dioxane) at 70°C for 1 hour to obtain a long-chain fluorine-containing acrylic acid polymer containing a carboxyl-terminated group.

[0050] (2) Preparation of long side chain fluorine-containing acrylic epoxy resin: add 2 mass parts of fluorine-containing acrylic long-chain polymers con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com