Preparation method of nickel nanopowder

A technology of nano-nickel powder and nickel salt, which is applied in the field of liquid-phase chemical reduction preparation of nano-nickel powder, which can solve the problems of difficulty in controlling the particle size and shape of the liquid-phase reduction method, difficulty in realizing industrial production, and difficulty in preparing carbon-based nickel. , to achieve the effect of simple and easy-to-control preparation method, stable production quality and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

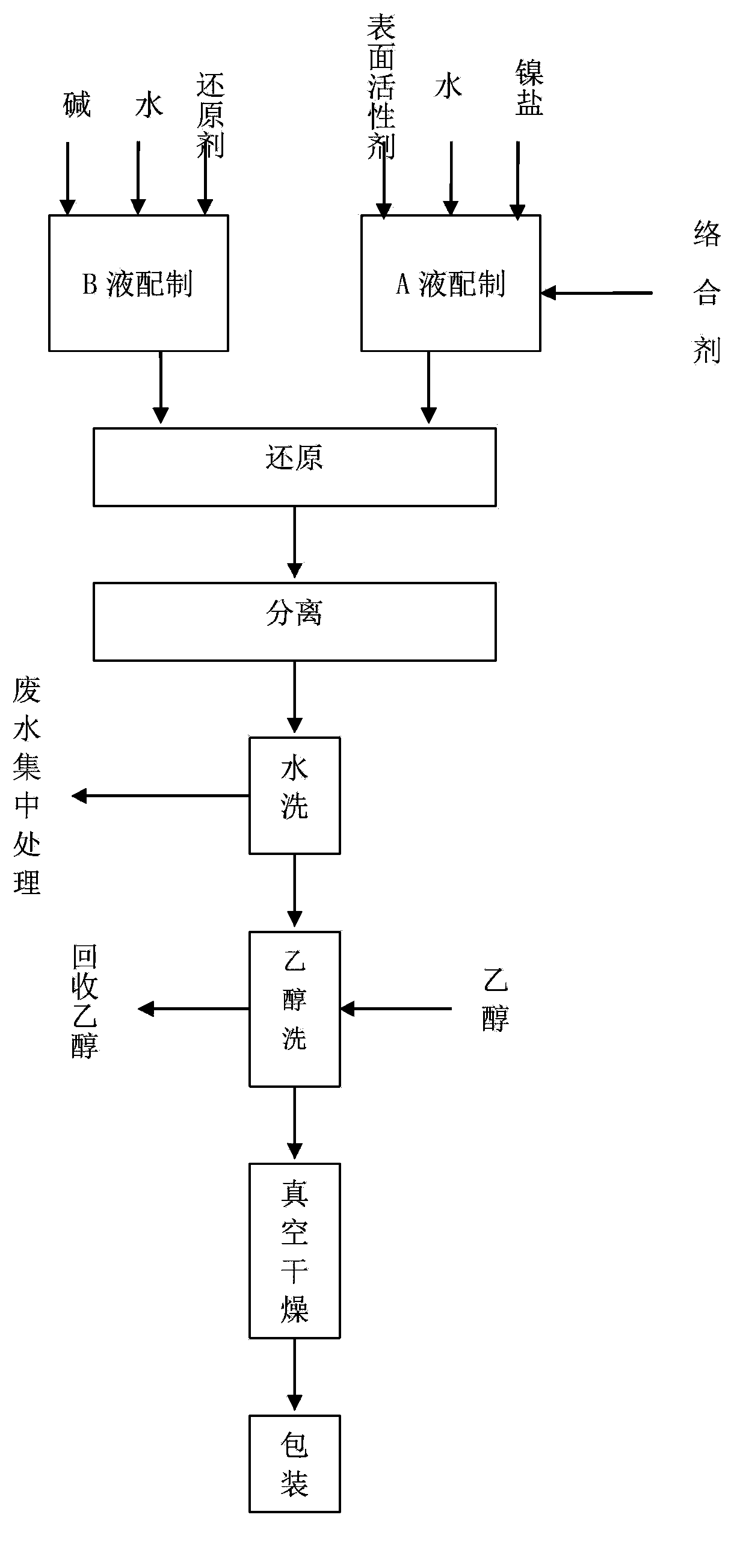

[0031] A preparation method of nano nickel powder, comprising:

[0032] (1) 0.075molNiCl 2 Dissolve 5g of PVP in water and mix evenly, then add 0.015mol of ammonia water and stir thoroughly to obtain 500ml of A solution; mix 0.5mol of N 2 h 4 ·H 2 O, 0.01mol sodium borohydride and 2.0mol NaOH are miscible in water to obtain 500ml B liquid;

[0033] (2) Heat liquid A to 90°C, add liquid B to liquid A, the feeding time is 30min, the temperature of the reaction system is maintained at 90°C and react for 50min, then add cold water to cool to room temperature (10-30°C); the reaction product is centrifuged Separation, the filter cake is washed with water to remove impurities in the filter cake, and the waste water is treated centrally; the washed filter cake is washed with absolute ethanol to remove water, and the absolute ethanol is recovered; the nickel powder filter cake washed with absolute ethanol is in the Ethanol and a small amount of water were removed in vacuum at 40°C ...

Embodiment 2

[0035] A preparation method of nano nickel powder, comprising:

[0036] (1) Add 0.1mol NiSO 4 Dissolve 10g of PVA in water and mix evenly, then add 0.02mol of ethylenediamine and stir thoroughly to obtain 300ml of A solution; add 0.7mol of N 2 h 4 ·H 2 O, 0.02mol potassium borohydride and 3.0mol KOH are miscible in water to obtain 700ml B liquid;

[0037] (2) Heat liquid A to 70°C, add liquid B to liquid A, the feeding time is 50min, the temperature of the reaction system is maintained at 70°C and react for 40min, then add cold water to cool to room temperature (10-30°C); the reaction product is centrifuged Separation, the filter cake is washed with water to remove impurities in the filter cake, and the waste water is treated centrally; the washed filter cake is washed with absolute ethanol to remove water, and the absolute ethanol is recovered; the nickel powder filter cake washed with absolute ethanol is in the Ethanol and trace moisture were removed under vacuum at 40°C...

Embodiment 3

[0039] A preparation method of nano nickel powder, comprising:

[0040] (1) Add 0.25molNi(NO 3 ) 2 Dissolve 20.0g PEG in water and mix evenly, then add 0.0125mol disodium edetate and stir well to obtain 250ml A solution; mix 1.2mol N 2 h 4 ·H 2 O, 0.03mol potassium borohydride and 5.0mol NaOH are miscible in water to obtain 750ml B liquid;

[0041](2) Heat liquid A to 60°C, add liquid B to liquid A, the feeding time is 60min, the temperature of the reaction system is maintained at 60°C and react for 40min, then add cold water to cool to room temperature (10-30°C); the reaction product is centrifuged Separation, the filter cake is washed with water to remove impurities in the filter cake, and the waste water is treated centrally; the washed filter cake is washed with absolute ethanol to remove water, and the absolute ethanol is recovered; the nickel powder filter cake washed with absolute ethanol is in the Ethanol and a small amount of water were removed in vacuum at 40° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com