Phosphor-containing nitrogen-containing structural type flame retardant polyhydric alcohol as well as preparation method and application thereof

A flame-retardant polyol and structural technology, which is applied in the field of phosphorus-containing nitrogen-containing structural flame-retardant polyol and its preparation, can solve the problem that the flame retardant performance of polyurethane rigid foam is not obvious, there is strong irritating hydrogen halide gas, and it is difficult to Meet environmental protection requirements and other issues, and achieve the effects of easy industrial production, easy operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] On a 1000mL three-neck flask, install a constant pressure dropping funnel and a reflux condenser, add 45.00g (1.50mol) of paraformaldehyde and 91.68g (1.50mol) of ethanolamine, stir and react at 20°C for 0.5h, then heat up under nitrogen protection After reacting at 60° C. for 2 hours, 94.11 g (0.50 mol) of phenol-ethanol solution with a mass fraction of 50% was slowly added dropwise, and refluxed for 4 hours to obtain a phenol-based Mannich-based polyol intermediate.

[0038] After the temperature of the system was lowered to 50°C, 207.00g (1.50mol) of diethyl phosphite and 45.00g (1.50mol) of paraformaldehyde were successively added to continue the reaction for 4h. Finally, the ethanol and the water produced by the reaction are removed by vacuum distillation to obtain a light yellow viscous liquid, which is a phosphorus-containing and nitrogen-containing structural flame-retardant polyol.

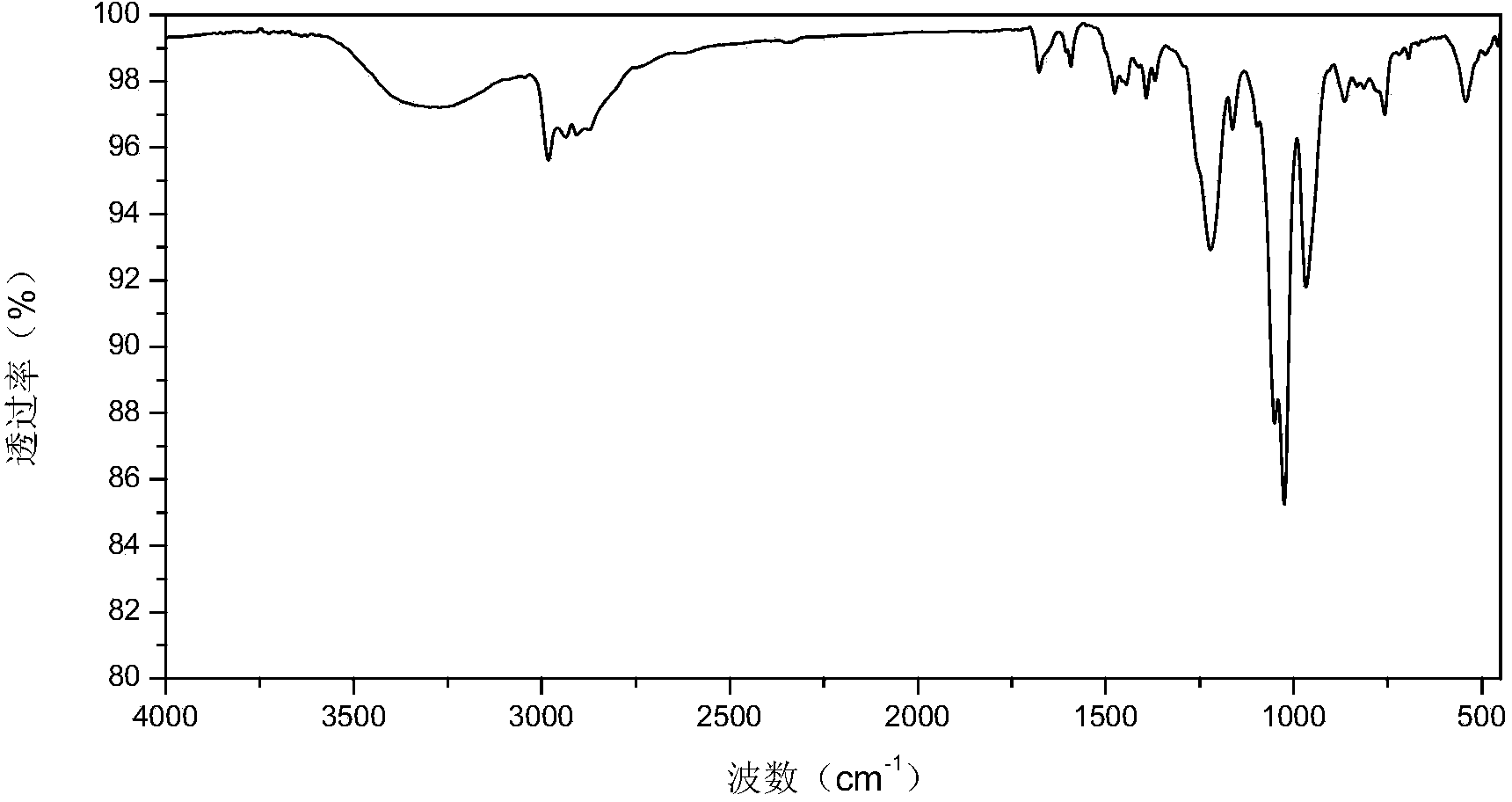

[0039] The infrared spectrogram of the phosphorus-containing and nitrogen-cont...

Embodiment 2

[0041] On a 1000mL three-neck flask, install a constant pressure dropping funnel and a reflux condenser, 45.00g (1.50mol) of paraformaldehyde and 91.68g (1.50mol) of ethanolamine, stir and react at 20°C for 1.0h, then heat up under nitrogen protection React at 80° C. for 2 hours, slowly drop 165.15 g (0.75 mol) of resorcinol ethanol solution with a mass fraction of 50%, and reflux for 2 hours to obtain a Mannich polyol intermediate.

[0042] After the temperature of the system was lowered to 55°C, 207.00g (1.50mol) of diethyl phosphite and 45.00g (1.50mol) of paraformaldehyde were successively added to continue the reaction for 4h. Finally, the ethanol and the water generated by the reaction are removed by vacuum distillation to obtain a light yellow viscous liquid, which is a phosphorus-containing and nitrogen-containing structure-type flame-retardant polyol.

Embodiment 3

[0044] On a 1000mL three-neck flask, install a constant pressure dropping funnel and a reflux condenser, 45.00g (1.50mol) of paraformaldehyde and 91.68g (1.50mol) of ethanolamine, stir and react at 20°C for 1.0h, then heat up under nitrogen protection After reacting at 70° C. for 2 hours, 297.33 g (1.50 mol) of phenol ethanol solution with a mass fraction of 50% was slowly added dropwise, and refluxed for 3 hours to obtain a Mannich polyol intermediate.

[0045] After the temperature of the system was lowered to 55°C, 207.00g (1.50mol) of diethyl phosphite and 45.00g (1.50mol) of paraformaldehyde were successively added to continue the reaction for 4h. Finally, the ethanol and the water generated by the reaction are removed by vacuum distillation to obtain a light yellow viscous liquid, which is a structural phosphorus-containing nitrogen-containing flame-retardant polyol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com