Method for treating oily sludge through multistage extraction-splitting coupling of supercritical fluid

A supercritical fluid and supercritical technology, applied in the field of oily sludge treatment, can solve the problems of high energy consumption, low degree of comprehensive utilization, difficulty in large-scale industrialization, etc., and achieve the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

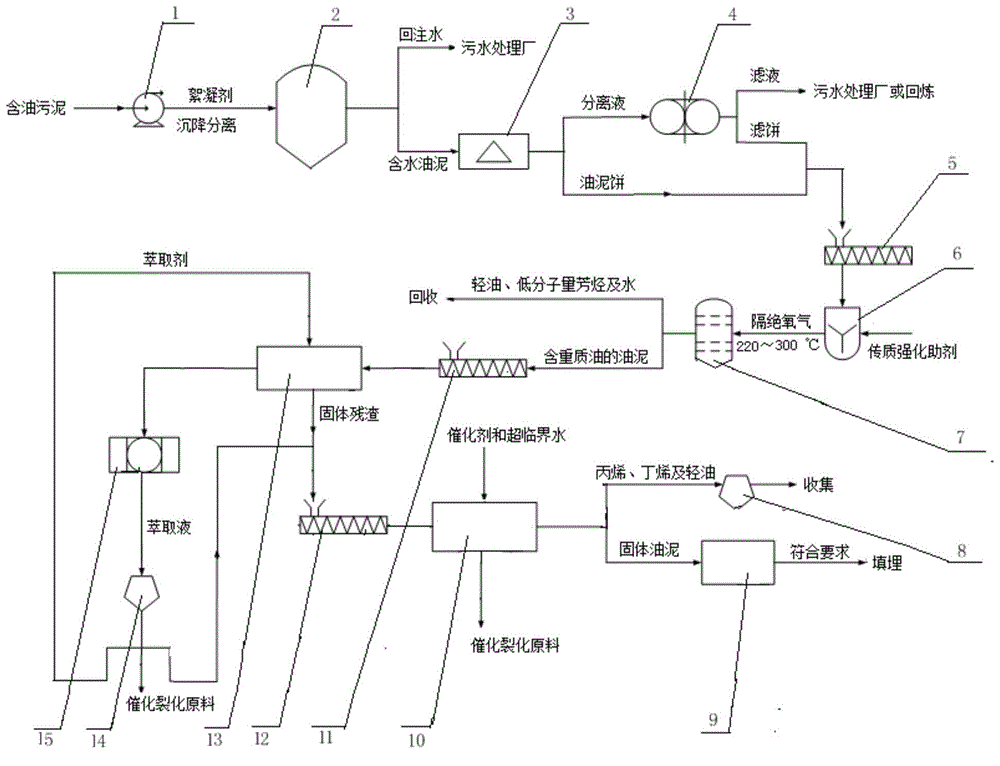

[0031] Taking the oily sludge produced in the sewage workshop of an oil refinery in northern Shaanxi as an example, the oily sludge is composed of the bottom sludge of the oil separation tank of the sewage plant, biochemical sludge and flotation tank scum, and its initial water content is 97%. Organic matter 2% (of which light oil components with a boiling point below 300°C account for 0.7%, heavy oil components account for 1.3%), and mud content is 1%. The specific treatment methods are as follows:

[0032] 1. Reduction, separation and treatment of oily sludge

[0033] Such as figure 1 As shown, the oily sludge is injected into the oil sludge thickening tank 2 with the mud pump 1, and then the cationic polyacrylamide and the fatty alcohol polyoxyethylene ether AEO-9 reverse phase demulsifier with a weight average molecular weight of 10000 are added in a mass ratio of 10: The mixture of 1 is subjected to sedimentation and separation, and the total amount added is 0.5% of the ...

Embodiment 2

[0044] Taking the oily sludge at the bottom of a crude oil settling tank of a joint station of an oil production plant in northern Shaanxi as an example, its initial water content is 40%, and it contains 35% organic matter (of which light oil components with a boiling point below 300°C account for 8%, and heavy oil components Accounting for 27%), the mud content is 25%, the specific treatment method is as follows:

[0045] 1. Reduction, separation and treatment of oily sludge

[0046] Such as figure 1 As shown, the oily sludge is injected into the oil sludge thickening tank 2 with the mud pump 1, and then the mixture of amphoteric polyacrylamide and polyether F-68 with a weight average molecular weight of 12000 is added for sedimentation and separation at a mass ratio of 10:2. The total amount added is 0.3% of the mass of the oily sludge. After staying for 12 hours, the water in the upper part of the sludge concentration tank 2 is separated and reinjected to the sewage treatm...

Embodiment 3

[0057] Taking the "three muds" produced by the sewage workshop of an oil refinery in northern Shaanxi and the oil sludge at the bottom of a crude oil settlement tank of an oil production plant combined station in northern Shaanxi mixed at a mass ratio of 1:6 as an example, the initial water content is 45%, containing Organic matter 35% (of which light oil components with a boiling point below 300°C account for 8%, heavy oil components account for 27%), and mud content is 20%. The specific treatment methods are as follows:

[0058] 1. Reduction, separation and treatment of oily sludge

[0059] Such as figure 1 As shown, the oily sludge is injected into the oil sludge thickening tank 2 with the mud pump 1, and then the mixture of amphoteric polyacrylamide with a weight average molecular weight of 20,000 and polyether polyol 330N is added in a mass ratio of 10:5 for sedimentation and separation. The total amount added is 0.1% of the mass of the oily sludge. After staying for 10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com