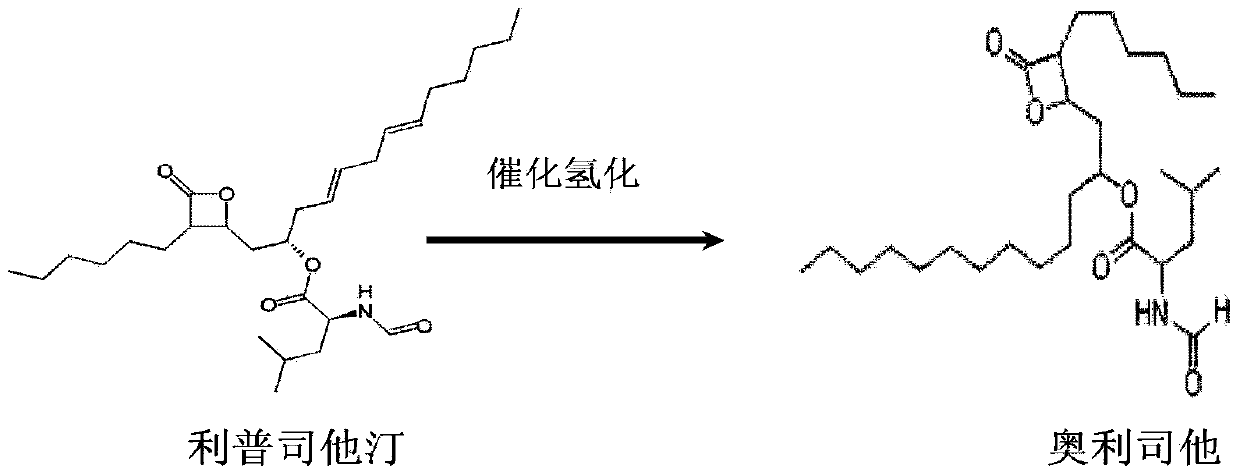

Preparation method of orlistat

A technology for orlistat and intermediates, applied in the field of preparation of orlistat, can solve the problems of low yield, high production cost, and high investment, and achieve the effects of high yield, easy operation, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Fermentation broth pretreatment: to 1.5m 3 Add 45kg of diatomaceous earth to the fermentation broth (fermentation unit 8.5g / L), adjust the pH to 4.5 with hydrochloric acid, stir for 1h, plate and frame press filter, and collect 360kg of filter cake;

[0052] 2) Leaching: use 2.88m 3 Industrial acetone extracts the filter cake obtained in step 1), extracts for 3h, and filters to obtain a clear, light red transparent filtrate containing orlistat intermediate 3.2m 3 ;

[0053] 3) Concentration and adjustment of solvent volume concentration: Concentrate the acetone solution of orlistat intermediate obtained in step 2) under reduced pressure with a falling film evaporator, and concentrate to a product concentration of 20g / L at a temperature of 30°C, add 150L of drinking water Regulate the volume concentration of aqueous acetone to be 65%;

[0054] 4) Non-polar solvent extraction: Add 480L of petroleum ether to the acetone / water solution of the orlistat intermediate pre...

Embodiment 2

[0062] 1) Fermentation broth pretreatment: to 1.45m 3 Add 70kg of perlite to the fermentation broth (fermentation unit 9.2g / L), adjust the pH to 4.7 with oxalic acid, stir for 2 hours, plate and frame filter, and collect 350kg of filter cake;

[0063] 2) Extraction: use 3.5m 3 Industrial methanol leached the filter cake obtained in step 1), leached for 5h, and plate-and-frame press-filtered to obtain a clear, light red transparent solution containing the orlistat intermediate 4m 3 ;

[0064] 3) Concentration and adjustment of solvent volume concentration: Concentrate the orlistat intermediate methanol solution obtained in step 2) under reduced pressure with a falling film evaporator, and concentrate it to a product concentration of 20g / L under temperature control at 30°C, add 170L for drinking Water regulates the volume concentration of methanol aqueous solution to be 62%;

[0065] 4) Non-polar solvent extraction: Add 670L heptane to the methanol / water solution of the orlis...

Embodiment 3

[0074] 1) Fermentation broth pretreatment: to 1.5m 3 Add 60kg of magnesium oxide to the fermentation broth (fermentation unit 8.8g / L), adjust the pH to 5.0 with oxalic acid, stir for 3h, filter, and collect 375kg of filter cake;

[0075] 2) Leaching: use 1.88m 3 Industrial ethanol extracts the filter cake obtained by filtering in step 1), extracts for 3h, and plate and frame press filter to obtain a clear, light red transparent solution containing orlistat intermediate 2.1m 3 ;

[0076] 3) Concentration and adjustment of solvent volume concentration: use a falling film evaporator to concentrate the orlistat intermediate ethanol solution obtained in step 2) under reduced pressure, and concentrate to a product concentration of 25g / L at a temperature of 30°C, and add 200L of drinking water Regulating the volumetric concentration of ethanol aqueous solution is 67%;

[0077] 4) Non-polar solvent extraction: Add 840L n-hexane to the ethanol / water solution of the orlistat intermed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com