Method for preparing trehalose and yeast extract by utilization of waste beer yeast

A technology for waste beer yeast and yeast paste, which is applied in the preparation of sugar derivatives, chemical instruments and methods, disaccharides, etc., can solve the problems of high price, microbial pollution, limitations, etc., and achieve the effect of high utilization value and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

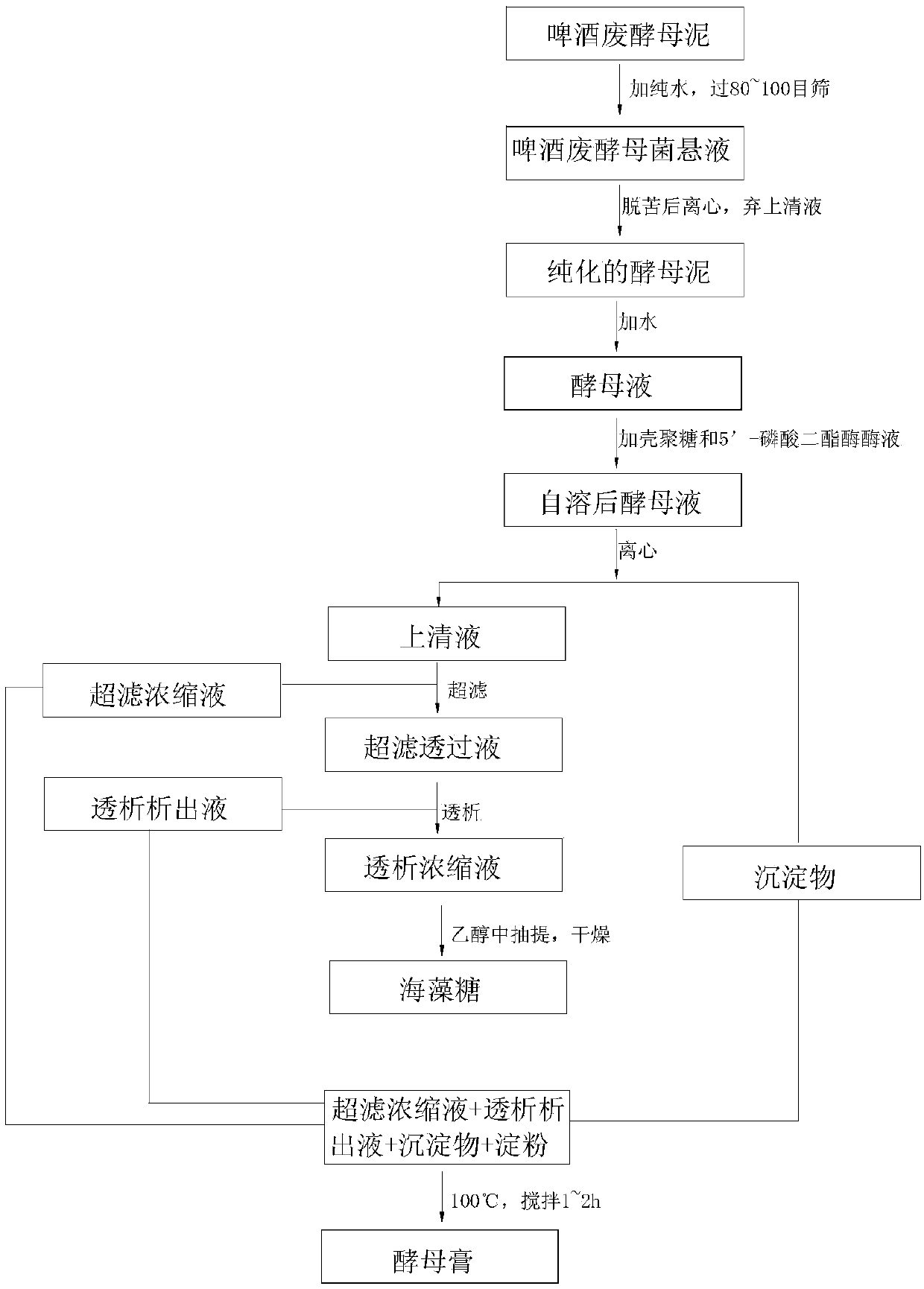

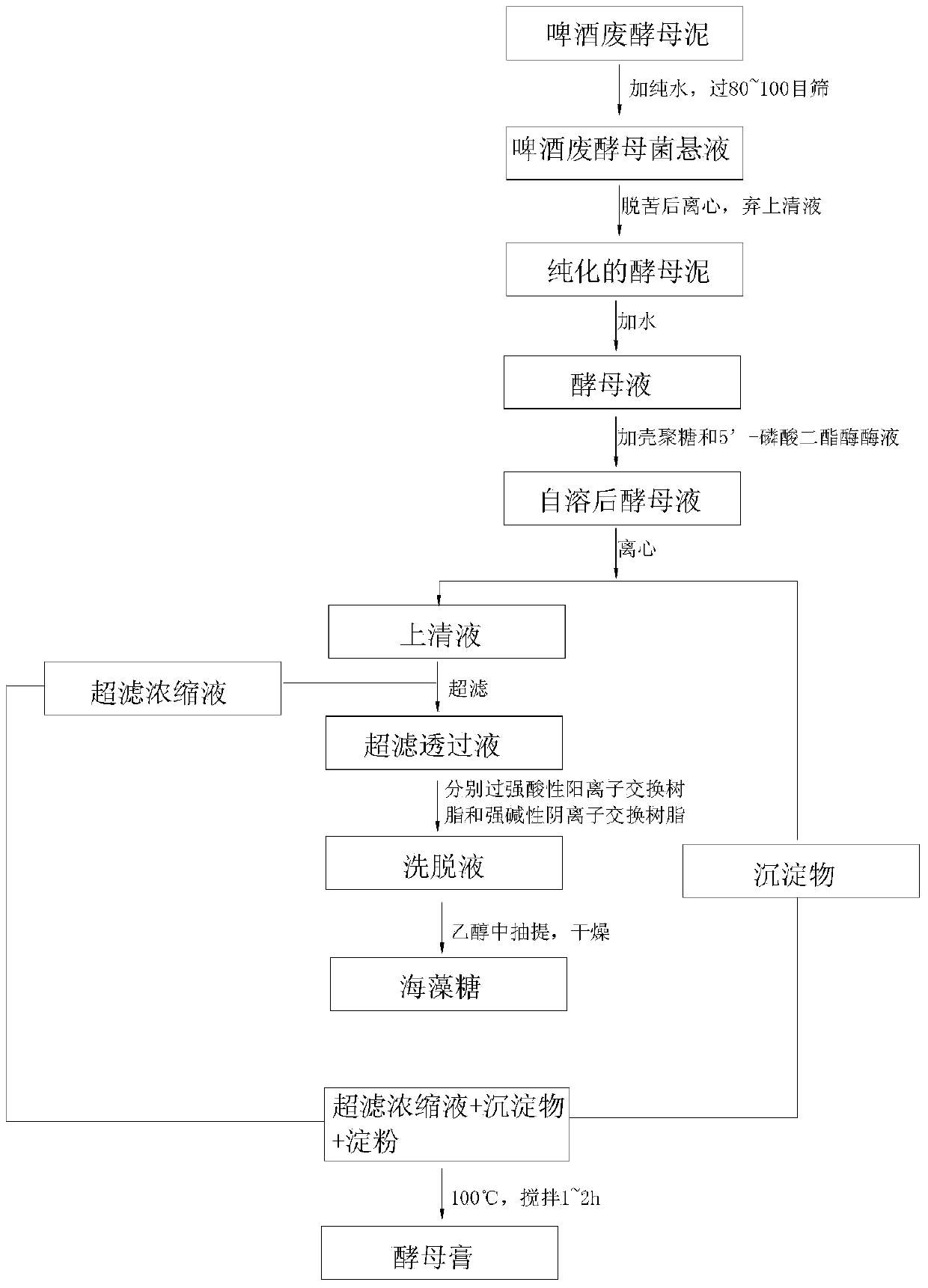

[0027] Such as figure 1 Shown, a kind of method utilizing beer waste yeast to prepare trehalose and yeast extract comprises the following steps:

[0028] 1) Washing, debittering and purification

[0029] Take the waste beer yeast mud, add pure water to the waste beer yeast mud, filter twice through 80~100 mesh sieve to obtain yeast suspension; add tartaric acid to the yeast suspension so that the mass fraction of tartaric acid in the solution is 5%, stir After debittering for 60 min, centrifuge at 4500 rpm for 10 min, discard the supernatant to obtain purified yeast sludge.

[0030] 2) Autolysis

[0031] Add pure water, chitosan acetic acid solution (1.5g chitosan dissolved in 100mL 2% acetic acid solution) and 5'-phosphodiesterase enzyme solution to the purified yeast sludge obtained in step 1) to adjust the pH value of 6.5, stirred at 45 ° C for 15 h to autolyze; the amount of pure water added was 3 times the quality of the purified yeast slime, and the amount of chitosan...

Embodiment 2

[0037] Such as figure 1 Shown, a kind of method utilizing beer waste yeast to prepare trehalose and yeast extract comprises the following steps:

[0038] 1) Washing, debittering and purification

[0039] Take the waste beer yeast sludge, add pure water to the waste beer yeast sludge, filter through 80~100 mesh sieve three times to obtain yeast suspension; add tartaric acid to the yeast suspension so that the mass fraction of tartaric acid in the solution is 7%, stir for 50min After debittering, centrifuge at 4000 rpm for 15 min, discard the supernatant to obtain purified yeast sludge.

[0040] 2) Autolysis

[0041]Add pure water, chitosan acetic acid solution (1.5g chitosan dissolved in 100mL 2% acetic acid solution) and 5'-phosphodiesterase enzyme solution to the purified yeast sludge obtained in step 1) to adjust the pH value was 5.5, and stirred at 38°C for 15 h to autolyze; the amount of pure water added was 5 times the mass of the purified yeast slime, and the amount o...

Embodiment 3

[0047] Such as figure 1 Shown, a kind of method utilizing beer waste yeast to prepare trehalose and yeast extract comprises the following steps:

[0048] 1) Washing, debittering and purification

[0049] Take the waste beer yeast sludge, add pure water to the waste beer yeast sludge, and filter twice through a 80-100 mesh sieve to obtain a yeast suspension; add sodium bicarbonate to the yeast suspension, so that the mass fraction of sodium bicarbonate in the solution is 0.2%, after stirring for 60 minutes to remove bitterness, centrifuge at 4000 rpm for 15 minutes, discard the supernatant to obtain purified yeast sludge.

[0050] 2) Autolysis

[0051] Add pure water, chitosan acetic acid solution (1.5g chitosan dissolved in 100mL 2% acetic acid solution) and 5'-phosphodiesterase enzyme solution to the purified yeast sludge obtained in step 1) to adjust the pH value was 4.5, and stirred at 35°C for 20 h to autolyze; the amount of pure water added was 4 times the mass of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com