Preparation method for nano porous metal materials

A metal material, nanoporous technology, applied in metal material coating process, nanotechnology, liquid chemical plating and other directions, to achieve great application prospects, low reaction temperature, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

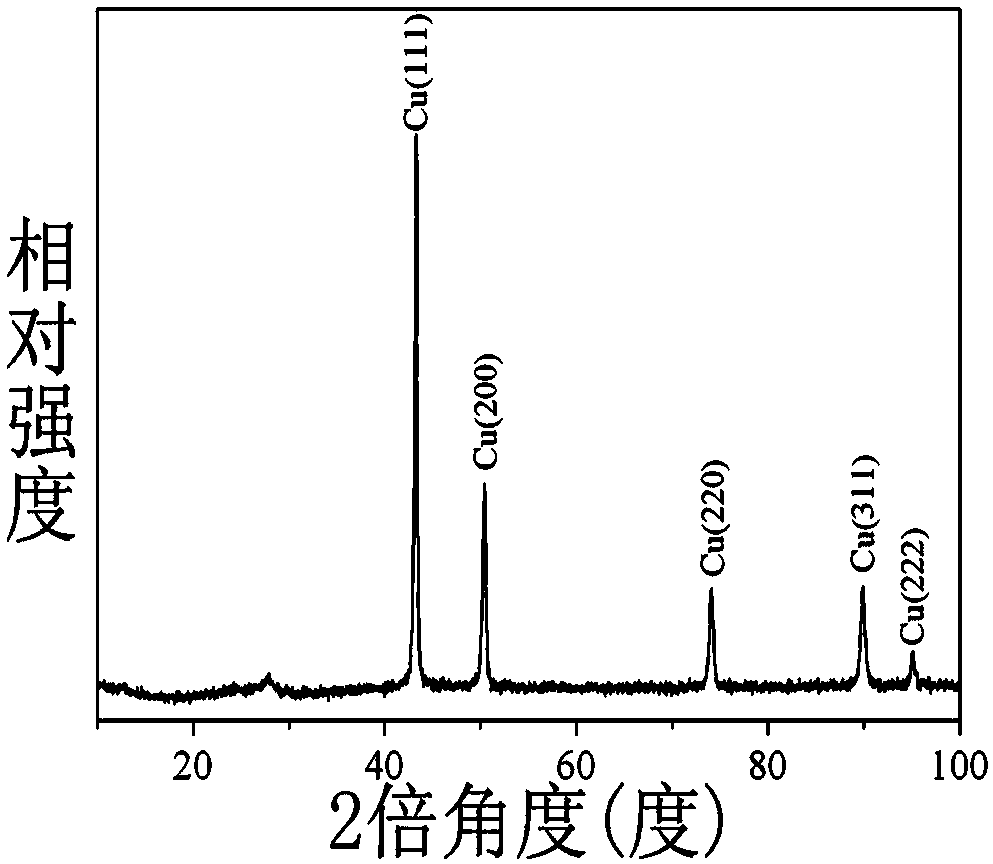

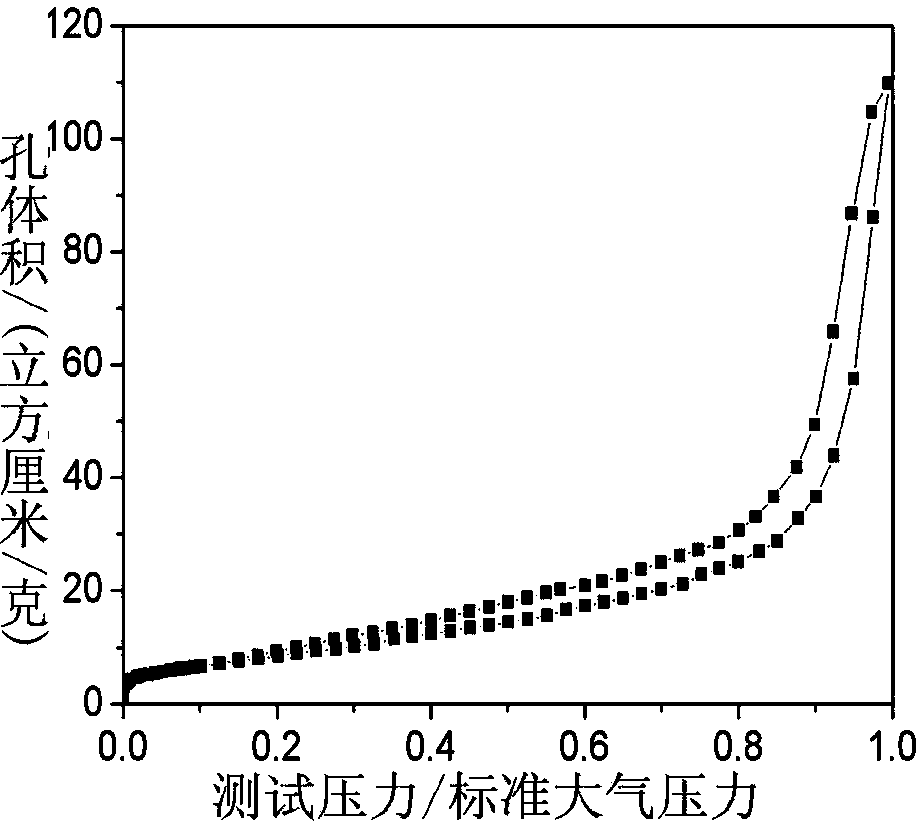

[0062] Example 1 Preparation of Nanoporous Copper Material

[0063] First prepare the electroless copper plating solution, the composition of the electroless copper plating solution is: sodium citrate 15g / L, boric acid 30g / L, copper sulfate 6g / L, sodium hypophosphite 30g / L. The melamine-formaldehyde hydrogel with evenly distributed Pd catalytic active centers in the structure was prepared by the sol-gel method, and the hydrogel was immersed in the prepared electroless copper plating solution. Implement electroless plating in the middle, the length of electroless plating is 90 days, wherein every 3 days change one electroless copper plating solution, the number of times of reaction is 15 times, obtains copper-hydrogel composite material, then this composite material is washed with deionized water, until There are no metal ions in the cleaning solution, and the solvent exchange is performed with acetone until the moisture content in the acetone after exchange is measured by a tr...

Embodiment 2

[0064] Example 2 Preparation of Nanoporous Copper Material

[0065] According to the preparation process of the nanoporous copper material described in Example 1, the difference is that the heat treatment temperature in the technical parameters is 600°C. The specific surface area of the prepared bulk nanoporous copper is 23.215m 2 g -1 , the average pore diameter is 7.316nm.

Embodiment 3

[0066] Example 3 Preparation of Nanoporous Copper Material

[0067] According to the preparation process of the nanoporous copper material described in Example 1, the difference is that the heat treatment temperature in the technical parameters is 700°C. The specific surface area of the prepared bulk nanoporous copper is 12.631m 2 g -1 , the average pore diameter is 8.529nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com