Silica aryne resin containing carborane unit in main chain framework and preparation method thereof

A technology for siloxane and carborane, which is applied in the field of siloxane resin and its preparation, can solve the problems of limiting the number of carborane units, hindering the reaction, high brittleness, etc., and achieves excellent mechanical properties and good processing performance. , the effect of excellent heat resistance and thermo-oxidative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

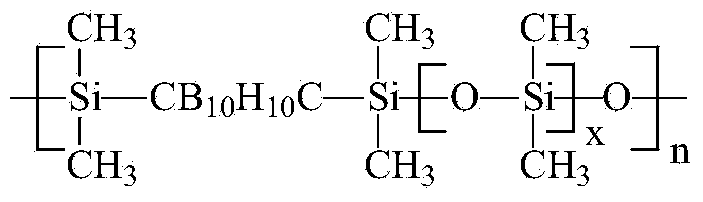

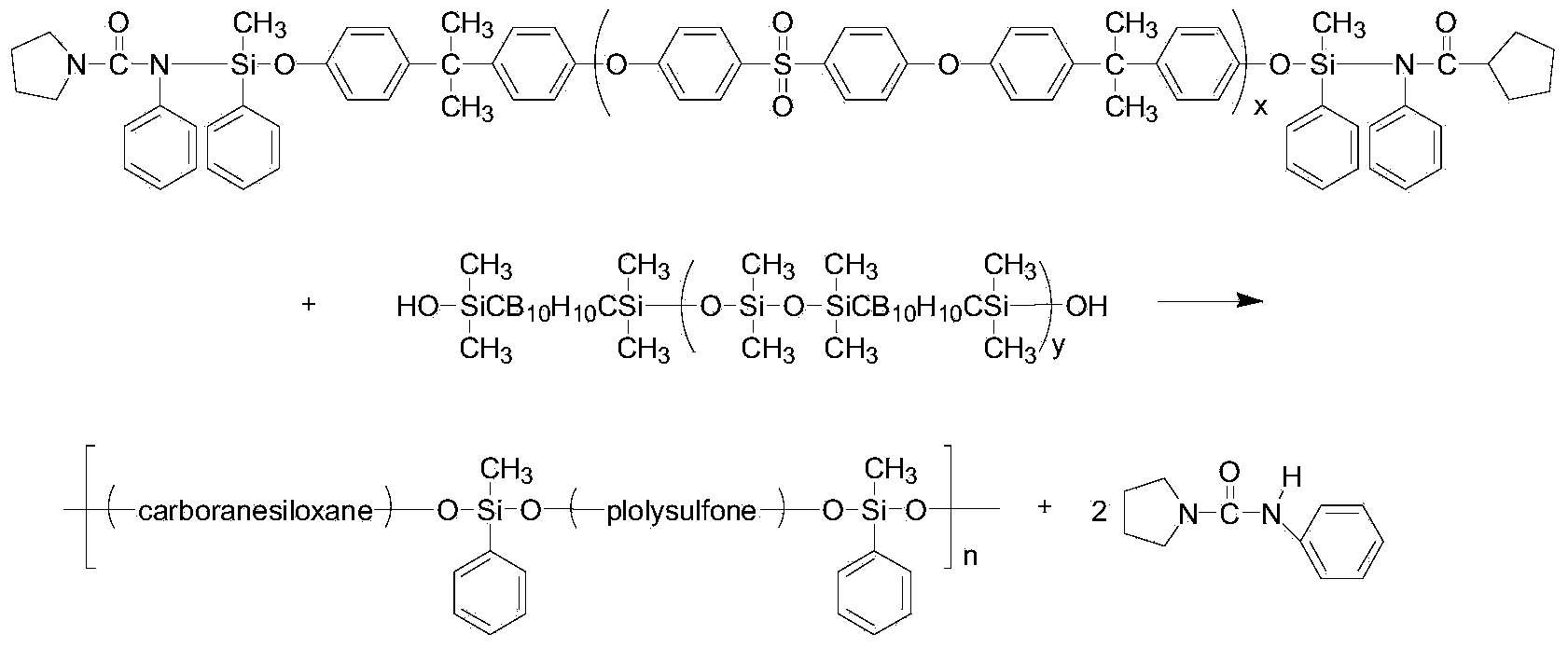

[0054] Preparation of disiloxane-type siloxyaryne resin CB-2-PSOA-10 containing carborane units in the main chain

[0055] 1) Synthesis of 1,3-dichloro-1,1,3,3-tetramethyldisiloxane

[0056] In a 500mL four-neck round bottom flask equipped with a constant pressure funnel, a spherical condenser and a magnetic Teflon stirrer, add PdCl 2 20mg and CCl 4 100mL, protected by nitrogen gas, stirred evenly, and added dropwise 26.8g (0.2mol) of 1,1,3,3-tetramethyldisiloxane CCl at room temperature 4 150mL solution, the dropwise addition time is about 2h, after the dropwise addition is completed, continue to stir at room temperature for 72h. After the reaction was completed, the solvent was removed and distilled under reduced pressure to obtain 32.5 g of a colorless and transparent liquid with a yield of 80.0%.

[0057] 2) Synthesis of disiloxane type siloxyaryne resin (2-PSOA)

[0058] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, a constant pressure funn...

Embodiment 2

[0065] Preparation of disiloxane-type siloxyaryne resin CB-2-PSOA-40 containing carborane units in the main chain

[0066] Under nitrogen protection, 250 mL of dry toluene, 10 g of 2-PSOA, 4 g of decaborane, and 20 mL of diethyl sulfide were added to a 500 mL flask, and the reactant was magnetically stirred at room temperature for 2 h. Then the solution was heated to 85°C and reacted for 48h. After the reaction was completed, 60 mL of methanol was added (hydrogen gas was generated), allowed to stand overnight, and then refluxed at 65° C. for 12 h. The reaction solution was cooled, washed with water, separated, and the organic phase was dried over anhydrous sodium sulfate. The solvent was distilled off under reduced pressure to obtain 12.1 g of a tan solid product with a yield of 86.4%. FTIR (KBr, cm -1 ): 3290 (v C-H ,≡C-H), 3062(v C-H , Ar) and (v C-H , cage), 2962 (v C-H , Si-CH 3 ), 2572(v B-H ), 2155(v C≡C ), 1257(v Si-C , Si-CH 3 ), 1048(v Si-O ); 1 H-NMR (C...

Embodiment 3

[0069] Preparation of High Molecular Weight Disiloxane Type Silicone Aryne Resin CB-2u-PSOA-20 Containing Carborane Units in Main Chain Skeleton

[0070] 1) Synthesis of high molecular weight disiloxane type silicone aryne resin (2u-PSOA)

[0071] In a 250mL four-necked flask equipped with a stirrer, a reflux condenser, a constant pressure funnel and a thermometer, nitrogen protection was applied, 6g (0.247mol) of magnesium powder and 50mL of tetrahydrofuran were added, and ethyl bromide was slowly added dropwise at room temperature with a constant pressure funnel The mixed solution of 21.6g (0.198mol) and 50mL tetrahydrofuran was added dropwise for about 1.5h. After the dropwise addition, reflux at 50° C. for 1.5 h, and cool to room temperature. At this time, the reaction solution is gray-black. Weigh a mixed solution of 11.35 g (0.090 mol) of diethynylbenzene and 50 mL of tetrahydrofuran, and slowly add it dropwise into the reaction system under cooling in an ice-water bath...

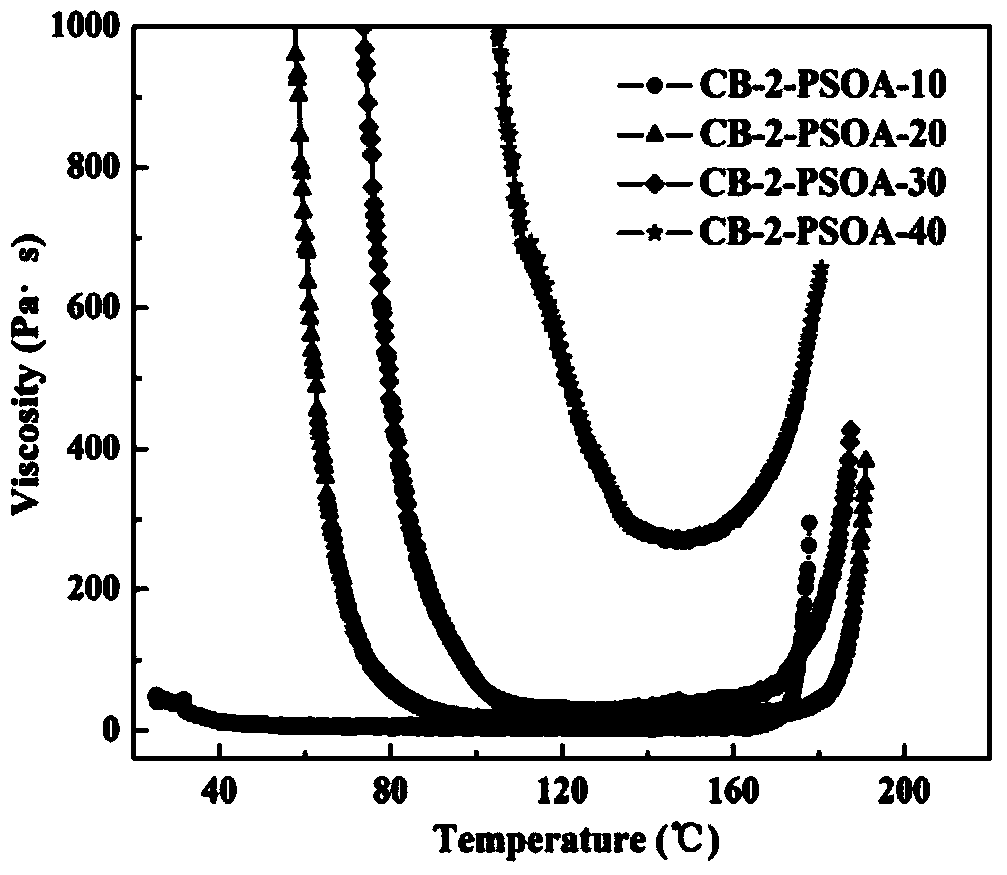

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting range | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com