Friction electric nanometer sensor

A nano-sensor and sensor technology, applied in the field of sensors, achieves the effects of convenient fabrication, cost reduction, and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

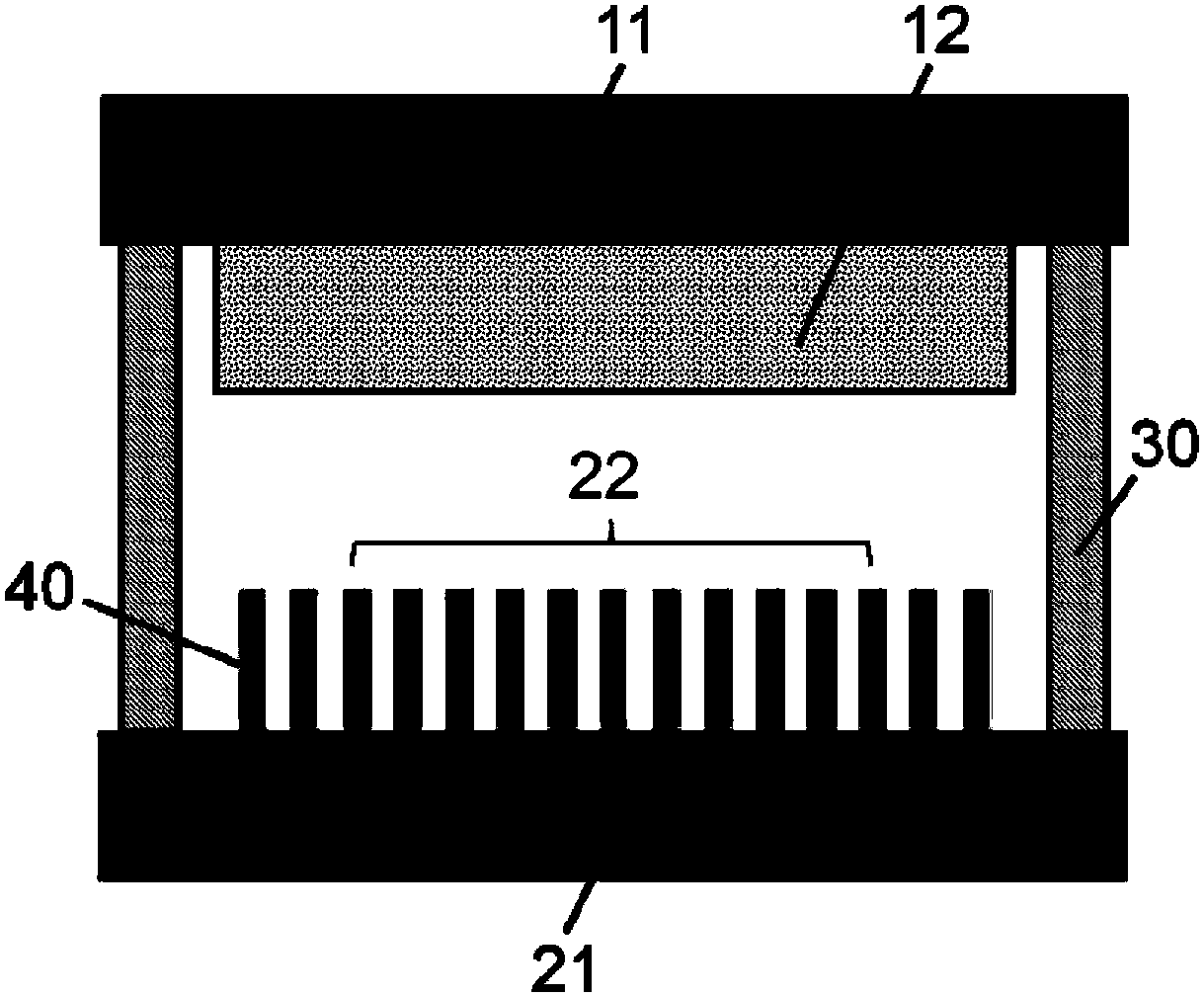

preparation example Construction

[0103] The present invention also provides a method for preparing the above-mentioned friction nanosensor, comprising the following steps:

[0104] (1) To clean the second conductive element, it can be cleaned with organic solvents and / or water, such as common cleaning agents such as acetone, ether, and ethanol;

[0105] (2) In-situ growth of nanostructures on the surface of the second conductive element to form the second friction layer; wherein the in-situ growth method can be selected according to the different types of the second conductive element and the nanostructure. In order to improve the charge transfer efficiency between the conductive element and the friction layer, it is preferable to use a metal conductive element, and use its corresponding metal oxide as a nanostructure, and the in-situ growth method can use hydrothermal reaction method, epitaxial growth method and electrochemical Etching method, etc.; preferably using hydrothermal reaction method and epitaxial...

Embodiment 1

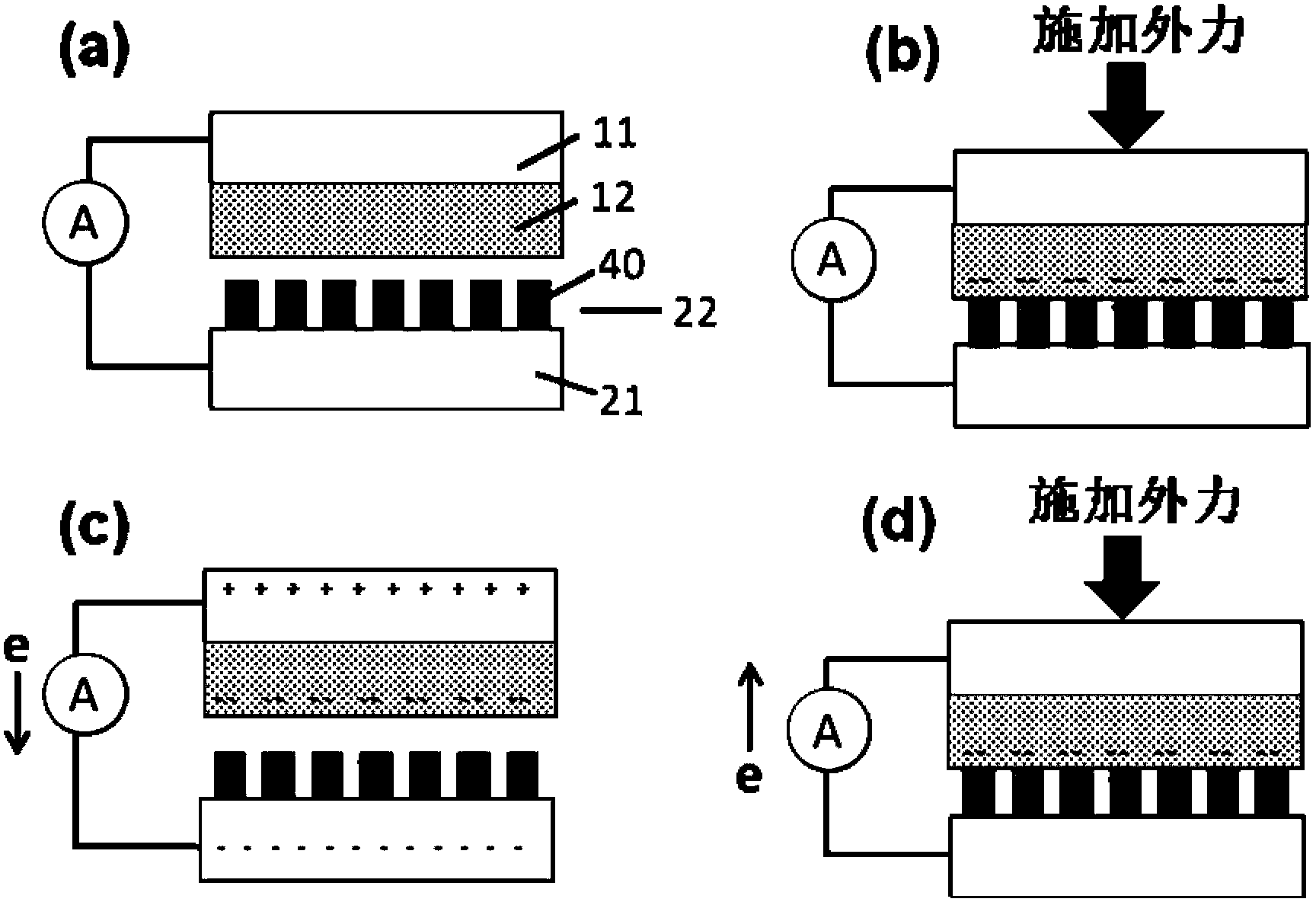

[0111] Example 1 Catechin (i.e. catechol) sensor

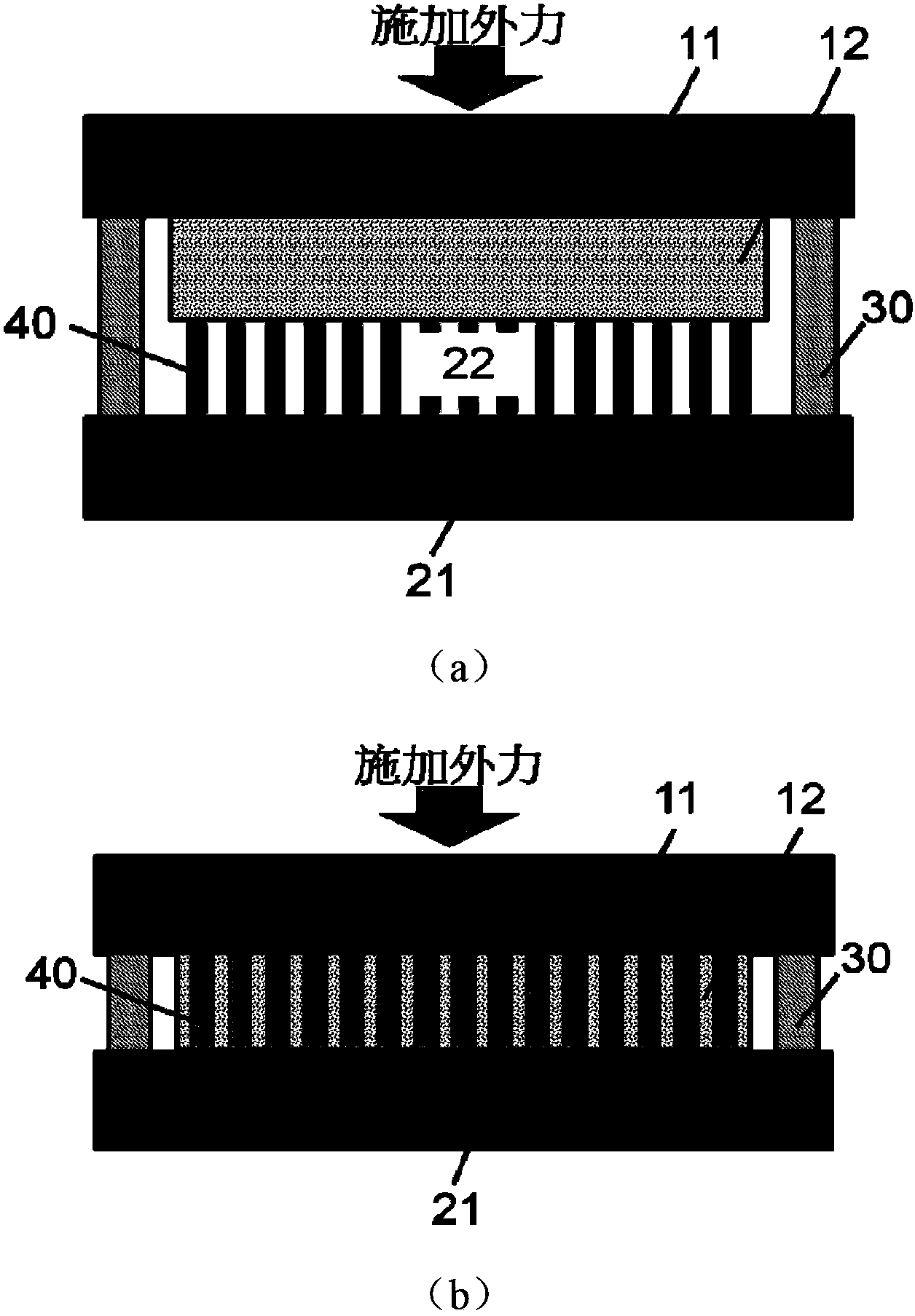

[0112] A metal gold film layer with a thickness of 50nm and a size of 1.8cm×0.6cm is used as the first conductive layer, and a polytetrafluoroethylene (PTFE) film layer with a thickness of 25μm is used as the first friction layer. A metal titanium thin film layer of 1.8cm×0.6cm is used as the second conductive layer, and a titanium dioxide nanowire array with a length of 4.2 μm is grown in situ on the titanium thin film by the hydrothermal method as the second friction layer. This titanium dioxide nanowire array can not only As a friction layer, it can also cause selective adsorption of catechins, and then become a catechin sensor, such as Figure 8 shown. Both the first insulating support layer and the second insulating support layer are plexiglass plates, and the two are connected by springs. For the connection method, see Figure 7 . When no external force is applied on the first support layer or the second support layer...

Embodiment 2

[0114] Embodiment 2 dopamine sensor

[0115] A metal aluminum sheet with a thickness of 5mm and a size of 2cm×2cm is used as the first conductive element, with a thickness of 40μm and a pyramid-shaped polydimethylsiloxane (PDMS) film layer as the first friction layer. A layer of photoresist is spin-coated on the silicon wafer, and a square window array with a side length of micron or sub-micron level is formed on the photoresist by photolithography; the first friction layer after photolithography is completed Chemical etching of hot potassium hydroxide forms a pyramid-shaped array of recessed structures at the window. A metal copper thin plate with a thickness of 5mm and a size of 2cm×2cm was used as the second conductive element, and a ferric oxide nanowire array with a length of 5 μm was grown in situ on it as the second friction layer. Use elastic rubber as an insulating space holder to connect the metal copper sheet and the metal aluminum sheet so that the polydimethylsil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com