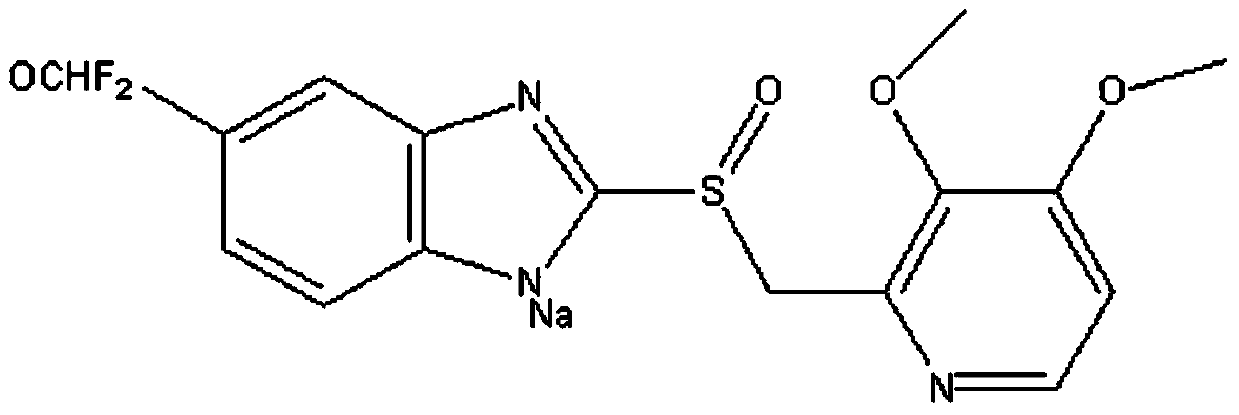

Pantoprazole sodium special ultrafine powder lyophilized preparation and preparation method thereof

A technology of pantoprazole sodium and ultrafine powder, which is applied in the field of medicine, can solve the problems of affecting the deposition effect of drug administration, low purity of pantoprazole sodium, affecting the exertion of drug effect, etc., and achieves good chemical reactivity, strong Surface activity and catalysis, the effect of improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 0.4mol of 2-bromo-3,4-lutidine as raw material and react with CuCN to produce 3,4-dimethoxy-2-cyanopyridine, which is then hydrolyzed in the presence of sodium hydroxide and reacted with diazonium Methane methylation produces methyl esters. The intermediate methyl ester is reduced and then chlorinated to form 2-chloromethyl-3,4-lutidine hydrochloride. Then it is condensed in ethanol solution to produce thioether, and finally oxidized by m-chloroperbenzoic acid in dichloromethane solution to produce crude pantoprazole sodium. The content of pantoprazole sodium is determined to be 86.78%.

[0027] Add anhydrous methanol to the crude product of pantoprazole sodium at a temperature of 10°C, stir and remove the methanol solution by suction filtration to obtain a filter cake of pantoprazole sodium. The amount of anhydrous methanol is pantoprazole sodium 75% of the volume, and then vigorously stirred to form a slurry, then suction filtered to remove the methanol solution to...

Embodiment 2

[0031] Dissolve pantoprazole sodium, calcium glutamate, and disodium edetate in water for injection containing 80 times the weight of pantoprazole sodium under constant speed stirring to obtain a composition solution; Activated carbon that removes heat source within hours is added to the composition solution, the ratio of the added weight of activated carbon to the volume of the drug solution is 0.15%; the combined drug solution is sterilized by moist heat at 121°C for 20 minutes. When the temperature of the drug solution is 70°C, it is filtered with two layers of superimposed membranes. Pass; when the sterilized and filtered combination drug solution is cooled to 10-15℃, adjust the pH value to 7.5-8.0 with 8% sodium hydroxide solution, and filter through the membrane; adjust the pH value to 6.5-7.5 with 8% hydrochloric acid solution , Determine the content of the combined drug components, aseptically dispense into pantoprazole sodium combined drug injection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com