Antibacterial polyelectrolyte composite nanofiber membrane and preparation method thereof

A technology of composite nanofibers and nanofiber membranes, which is applied in the field of biomedical materials and medical devices, can solve the problems such as the lack of antibacterial properties of nanobacterial cellulose membranes, the unsatisfactory effect of wound healing, and the inability to inhibit wound infection, and achieve good results. The effects of biodegradability, simple and easy preparation, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

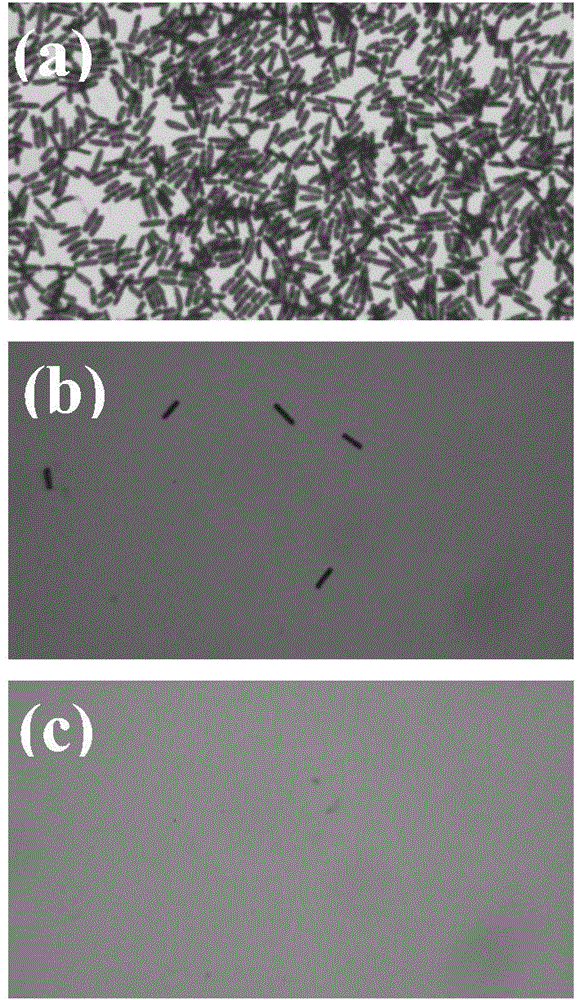

Image

Examples

preparation example Construction

[0027] The preparation method of described antibacterial polyelectrolyte composite nanofiber membrane comprises the steps:

[0028] (1) The commercially available bacterial cellulose nanofiber membrane is oxidized and modified by using sodium bromide, sodium hypochlorite, and tetramethylpiperidine to obtain a negatively charged bacterial cellulose nanofiber membrane, and freeze-dried; for specific methods, refer to CN101182561A nano-bacteria fiber The method of aldolization modification is described in the detailed description.

[0029] (2) Immerse the negatively charged basement membrane prepared in step (1) in a chitosan cationic polymer solution with a concentration of 0.1 to 50 g / L, take it out after 1 to 10 minutes, and wash it with deionized water Net surface residual polycation solution;

[0030] (3) Then immerse the membrane in a polyanion solution with a concentration of 0.1 to 50 g / L, take it out after 1 to 10 minutes, wash the residual polyanion solution on the sur...

Embodiment 1

[0037] Bacterial cellulose film (specification model 25*35cm; thickness 3-4mm; supplier Hainan Yide Food Co., Ltd.) was obtained by fermentation of Acetobacter xylinum. In an aqueous solution of sodium, 12wt% sodium hypochlorite, and 1wt% tetramethylpiperidine, stir constantly, react at 0-4° C. for 4 hours, and adjust the pH to 10 with sodium hydroxide. After the reaction was completed, the oxidized bacterial cellulose membrane was fully washed with deionized water and freeze-dried. Immerse the oxidized bacterial cellulose membrane in the quaternized N-aryl chitosan with a concentration of 10g / L, take it out after 10 minutes, wash the residual polycation solution on the surface with deionized water, and freeze-dry to obtain Bacterial cellulose nanofiber membranes containing quaternized N-aryl chitosan.

Embodiment 2

[0039] Bacterial cellulose film (specification model 25*35cm; thickness 3-4mm; supplier Hainan Yide Food Co., Ltd.) was obtained by fermentation of Acetobacter xylinum. In an aqueous solution of sodium, 10wt% sodium hypochlorite, and 1wt% tetramethylpiperidine, stir constantly, react at 0-4° C. for 6 hours, and adjust the pH to 11 with sodium hydroxide. After the reaction was completed, the oxidized bacterial cellulose membrane was fully washed with deionized water and freeze-dried. Immerse the oxidized bacterial cellulose membrane in the chitosan cationic solution containing hydroxypropyl trimethyl quaternary ammonium salt with a concentration of 1g / L, take it out after 2 minutes, wash the residual polycation solution on the surface with deionized water, and continue Soak the membrane in a sodium hyaluronate polyanion solution with a concentration of 1 g / L, take it out after 2 minutes, wash the residual polyanion solution on the surface with deionized water, and repeat the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com