Treatment method of copper-containing industrial wastewater

A technology for industrial wastewater and treatment methods, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as inability to separate in depth, limit applications, and insufficient treatment, and achieve wastewater Good treatment effect, more precipitation generation, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

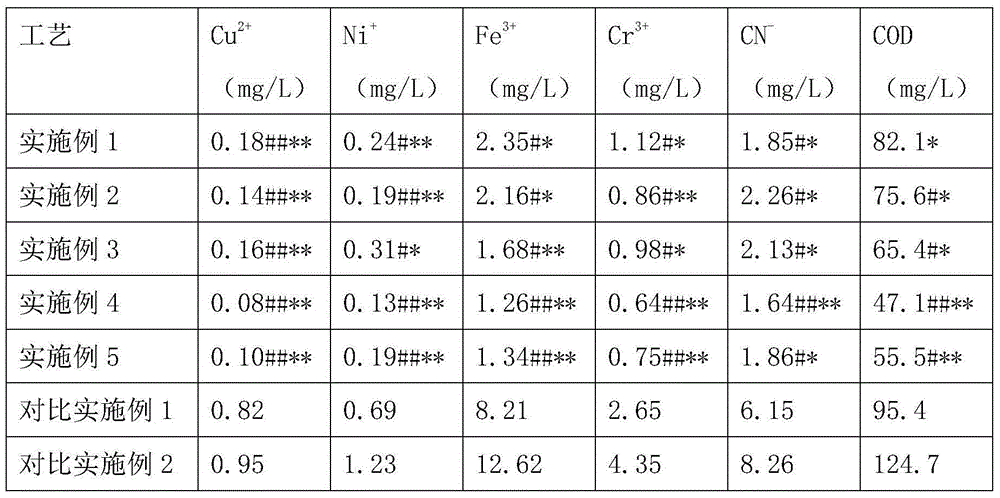

Examples

Embodiment 1

[0021] Embodiment 1 A kind of treatment method of copper-containing industrial wastewater

[0022] A treatment method for copper-containing industrial wastewater, comprising the steps of:

[0023] 1) Iron-carbon micro-electrolysis: adjust the pH of the copper-containing industrial wastewater to 2.0, add iron-carbon micro-electrolysis particles to the copper-containing wastewater, and react for 3 hours; wherein the preparation method of the iron-carbon micro-electrolysis particles is: by weight Accurately weigh 40 parts of iron filings, 20 parts of activated carbon, 10 parts of fly ash, 4 parts of ferrous sulfate, 5 parts of diatomaceous earth, 3 parts of quicklime, and 3 parts of magnesium chloride. Water glass, add 3 times the volume of water of the mixture mass and stir evenly, then extrude the mixture mechanically to obtain spherical particles with a diameter of 60mm, dry the spherical particles at 50°C for 3 hours after natural drying, and isolate the air sintering at 850...

Embodiment 2

[0027] Embodiment 2 A kind of treatment method of copper-containing industrial wastewater

[0028] A treatment method for copper-containing industrial wastewater, comprising the steps of:

[0029] 1) Iron-carbon micro-electrolysis: adjust the pH of the copper-containing industrial wastewater to 3.0, add iron-carbon micro-electrolysis particles to the copper-containing wastewater, and react for 5 hours; the preparation method of the iron-carbon micro-electrolysis particles is: by weight Accurately weigh 40 parts of iron filings, 20 parts of activated carbon, 10 parts of fly ash, 4 parts of ferrous sulfate, 5 parts of diatomaceous earth, 3 parts of quicklime, and 3 parts of magnesium chloride. Water glass, add water 3 times the volume of the mixture and stir evenly, then extrude the mixture mechanically to obtain spherical particles with a diameter of 60mm, dry the spherical particles at 100°C for 2 hours after natural drying, and isolate the air sintering at 1000° C. for 2 hou...

Embodiment 3

[0033] Embodiment 3 A kind of treatment method of copper-containing industrial wastewater

[0034] A treatment method for copper-containing industrial wastewater, comprising the steps of:

[0035] 1) Iron-carbon micro-electrolysis: adjust the pH of the copper-containing industrial wastewater to 2.5, add iron-carbon micro-electrolysis particles to the copper-containing wastewater, and react for 4 hours; wherein the preparation method of the iron-carbon micro-electrolysis particles is: by weight Accurately weigh 40 parts of iron filings, 20 parts of activated carbon, 10 parts of fly ash, 4 parts of ferrous sulfate, 5 parts of diatomaceous earth, 3 parts of quicklime, and 3 parts of magnesium chloride. Water glass, add 3 times the volume of water of the mixture mass and stir evenly, then extrude the mixture mechanically to obtain spherical particles with a diameter of 60mm, dry the spherical particles at 80°C for 3 hours after natural drying, and isolate the air sintering at 900...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com