Weather-resistant power pipe

A weather resistance and power technology, applied in the field of power pipes, can solve the problems of the original performance decline, low density and instability of PP materials, and achieve the effects of improving rigidity, reducing size and improving lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

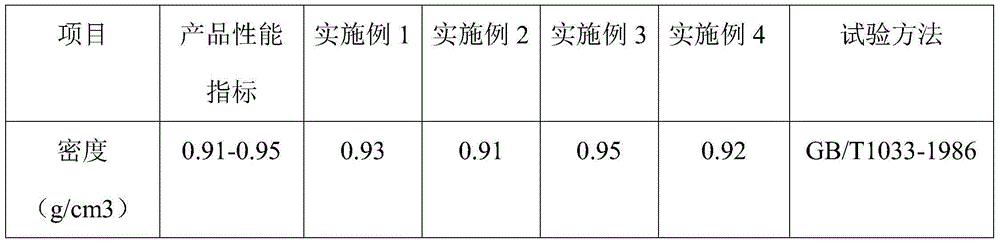

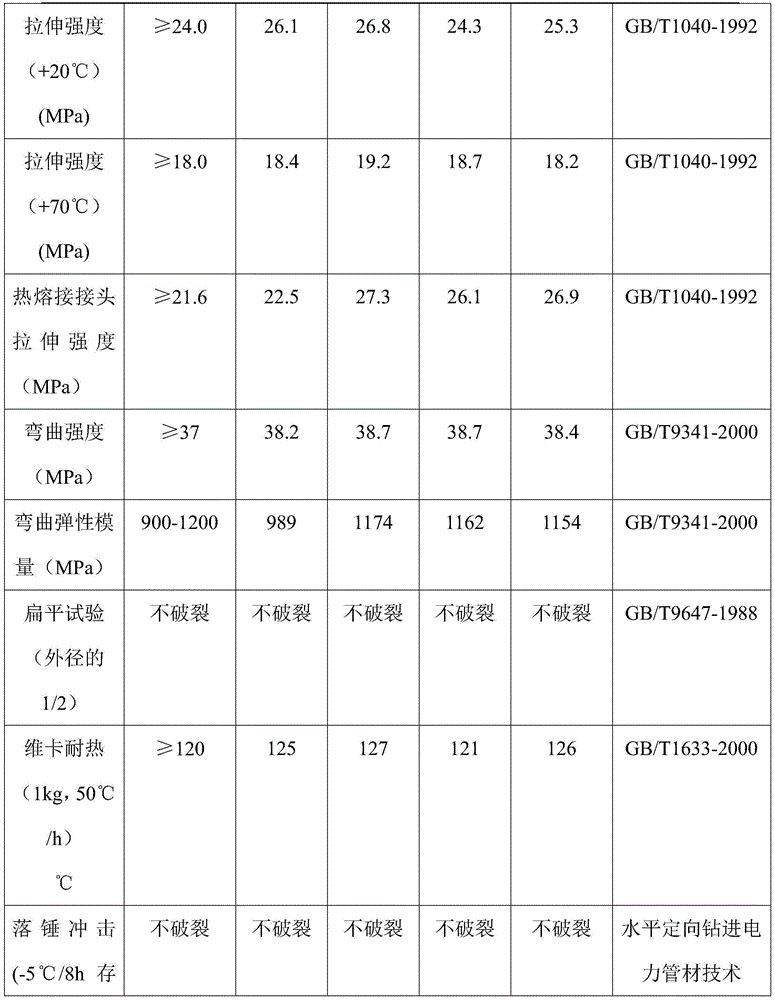

Examples

Embodiment 1

[0026] The weather-resistant electric pipe material of the present invention, its raw material comprises by weight: 80 parts of polypropylene, 7 parts of silicon rubber particles, 3.4 parts of active light calcium carbonate, 0.2 part of zinc oxide, 0.5 part of flaky talcum powder, calcined kaolin 3.6 parts, 1.3 parts of brucite powder, 12 parts of modified silica fume, 3 parts of modified attapulgite, 0.2 parts of colorant, 5 parts of new nucleating agent, 1.6 parts of antioxidant, 1.1 parts of polytetrafluoroethylene, 2 parts of toughening masterbatch, 6 parts of melamine cyanurate, 5 parts of modified whiskers, and 1 part of stabilizer;

[0027] The modified attapulgite is prepared by the following process: 2 parts of polypropylene grafted maleic anhydride and 3 parts of decahydronaphthalene are heated and dissolved at 130°C, and then 20 parts of attapulgite are added. Ultrasonic oscillation for 1.3h, vacuum drying at 75°C for 25h to obtain modified attapulgite;

[0028] Th...

Embodiment 2

[0030] The weather-resistant electric pipe material of the present invention, its raw material comprises by weight: 120 parts of polypropylene, 11 parts of silicon rubber particles, 2 parts of active light calcium carbonate, 0.4 part of zinc oxide, 4 parts of flaky talcum powder, calcined kaolin 5 parts, 0.3 parts of brucite powder, 10 parts of modified silica fume, 2 parts of modified attapulgite, 3 parts of colorant, 2 parts of new nucleating agent, 2.7 parts of antioxidant, 0.5 part of polytetrafluoroethylene, 10.2 parts of toughening masterbatch, 10 parts of melamine cyanurate, 15 parts of modified whiskers, 1.5 parts of stabilizer;

[0031] The modified attapulgite is prepared by the following process: heat and dissolve 2.26 parts of polypropylene grafted maleic anhydride and 3.6 parts of decahydronaphthalene at 138°C, add 28 parts of attapulgite, and heat at 89°C Under ultrasonic vibration for 0.5h, vacuum drying at 58°C for 19h to obtain modified attapulgite;

[0032] ...

Embodiment 3

[0037] The weather-resistant power pipe material of the present invention, its raw materials include by weight: 112 parts of polypropylene, 15 parts of silicon rubber particles, 4.8 parts of active light calcium carbonate, 0.8 parts of zinc oxide, 3 parts of flaky talcum powder, calcined kaolin 4 parts, 3 parts of brucite powder, 25 parts of modified silica fume, 5 parts of modified attapulgite, 2.4 parts of colorant, 5.9 parts of new nucleating agent, 1 part of antioxidant, 3 parts of polytetrafluoroethylene, 12 parts of toughening masterbatch, 4 parts of melamine cyanurate, 8 parts of modified whiskers, and 1.4 parts of stabilizer;

[0038] The modified attapulgite is prepared by the following process: 3 parts of polypropylene-grafted maleic anhydride and 5 parts of decahydronaphthalene are heated and dissolved at 132°C, and then 35 parts of attapulgite are added, and at 75°C Ultrasonic vibration for 1.5h, vacuum drying at 50°C for 15h to obtain modified attapulgite;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com