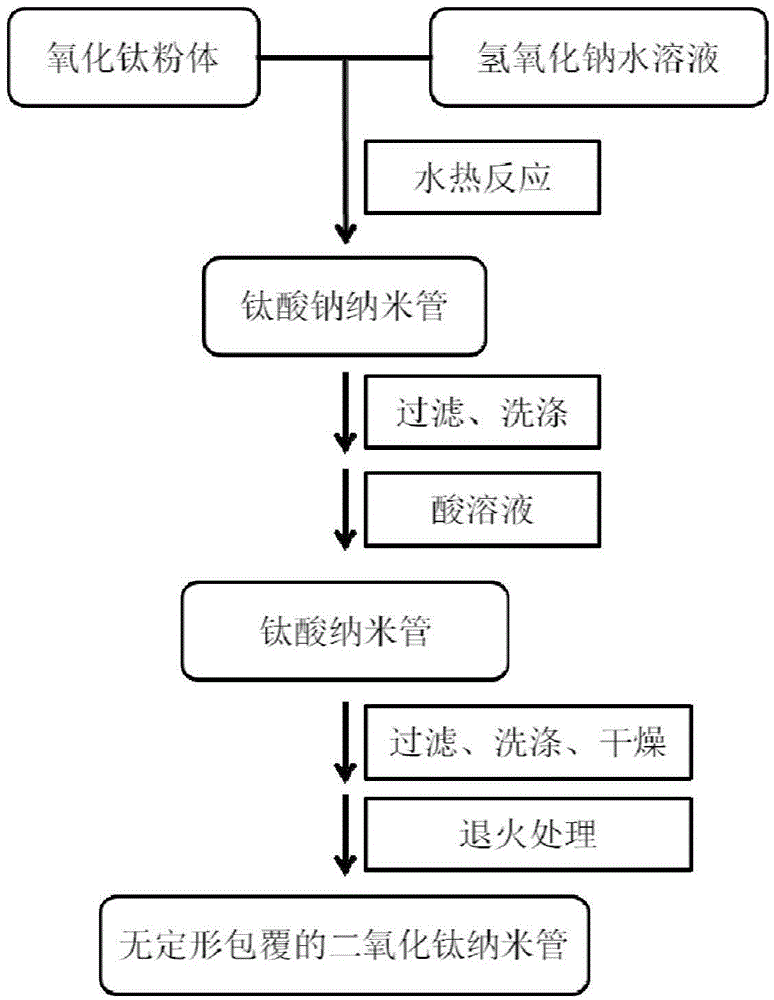

Preparation method and application of TiO2 nanotube coated with amorphous layer

A nanotube, amorphous technology, applied in chemical instruments and methods, physical/chemical process catalysts, titanium dioxide, etc., can solve the problems of low utilization efficiency, low mineralization rate, slow degradation rate, etc., to improve absorption performance, high Mineralization rate, simple effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Disperse 2g of titanium oxide powder (Degussa P25) in 40mL of 10mol / L sodium hydroxide aqueous solution, transfer the solution to a hydrothermal kettle, heat to 150°C, and keep the temperature constant for 24 hours. When the temperature of the reaction kettle drops to room temperature, pour Remove the upper clear layer, transfer the white solid substance at the bottom to a beaker, ultrasonically disperse, and wash with deionized water several times to remove excess sodium hydroxide. The obtained white solid was dispersed into 40 mL of 0.05 mol / L nitric acid solution, and after aging for 6 hours, the white solid was separated by centrifugation. After repeating the above acid exchange process twice, wash with deionized water several times, centrifuge until the pH value of the washing solution reaches neutral, and dry in vacuum at 60°C to obtain titanate nanotube samples.

Embodiment 2

[0045] The titanate nanotube sample obtained in Example 1 was put into a muffle furnace, and the temperature was raised to 350° C. under an air atmosphere, and kept at a constant temperature for 4 hours to obtain a titanium dioxide nanotube sample coated with an amorphous layer.

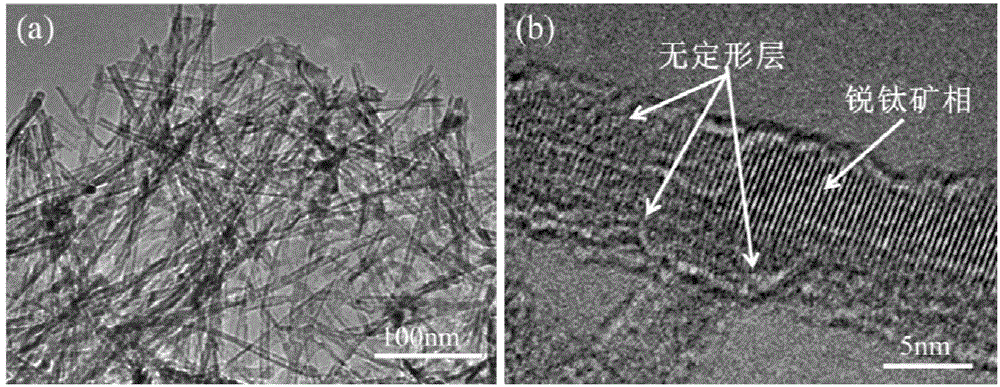

[0046] The transmission electron microscope picture of the titanium dioxide nanotube sample is as follows figure 2 As shown, in the high-resolution transmission electron microscope image (b), it can be seen that the main body of the titanium dioxide nanotube sample is an anatase phase with a one-dimensional tubular structure, and the surface layer is amorphous titanium dioxide.

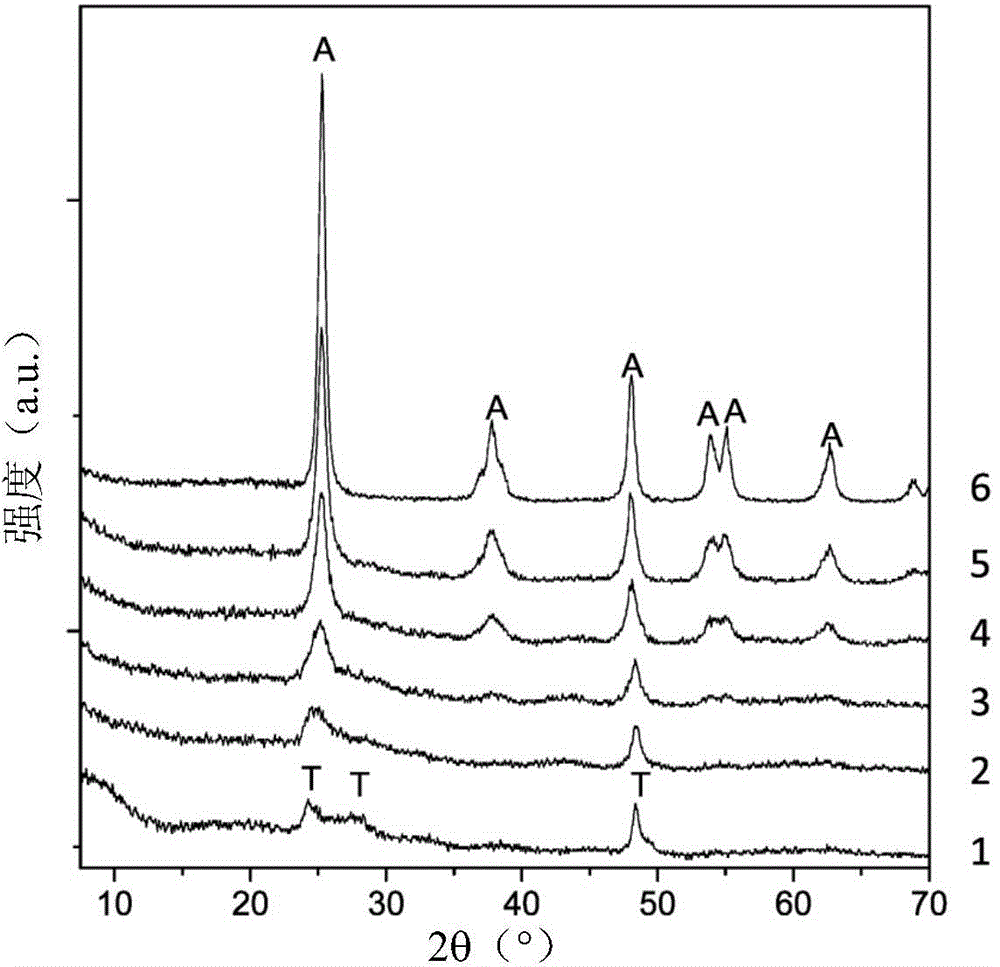

[0047] The titanate nanotubes prepared in Example 1, and the XRD patterns of the titanium dioxide nanotubes after annealing at different treatment temperatures for 4 hours are as follows image 3 As shown, it can be seen that with the increase of annealing temperature, the content of titanium dioxide in the anatase phase gr...

Embodiment 3

[0049] 30 mg of the titanium dioxide sample prepared in Example 2 was ultrasonically dispersed in 100 mL of 10 mg / L rhodamine B aqueous solution, and after stirring for 30 minutes in a dark place, visible light photosensitized degradation of rhodamine B was achieved under the irradiation of a 300W Xe lamp. The ultraviolet component in is filtered out by cut-off filter (exit light wavelength>420nm). Samples were taken at different time intervals, the titanium oxide nanotubes were removed by centrifugation, and the absorption spectrum of the supernatant was measured to obtain Figure 4 The change process shown, while measuring the total carbon content (TOC) in the solution to get Figure 5 .

[0050] from Figure 4 It can be seen that the photosensitized degradation process of rhodamine B is completed in about 1 hour. With commercial P25 particles (Degussa, Degussa) as a contrast, using Rhodamine B as a substitute for organic pollutants, under the same conditions, the photose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com