Polyhydroxy p-phenylene benzo bisoxazole polymer and preparation and application thereof

A technology of hydroxybenzoxazole and benzobisoxazole, which is applied in the field of benzobisoxazole polymers, can solve the problems of thermal performance degradation and low tensile strength of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1 Preparation of AB type monomer and precursor thereof

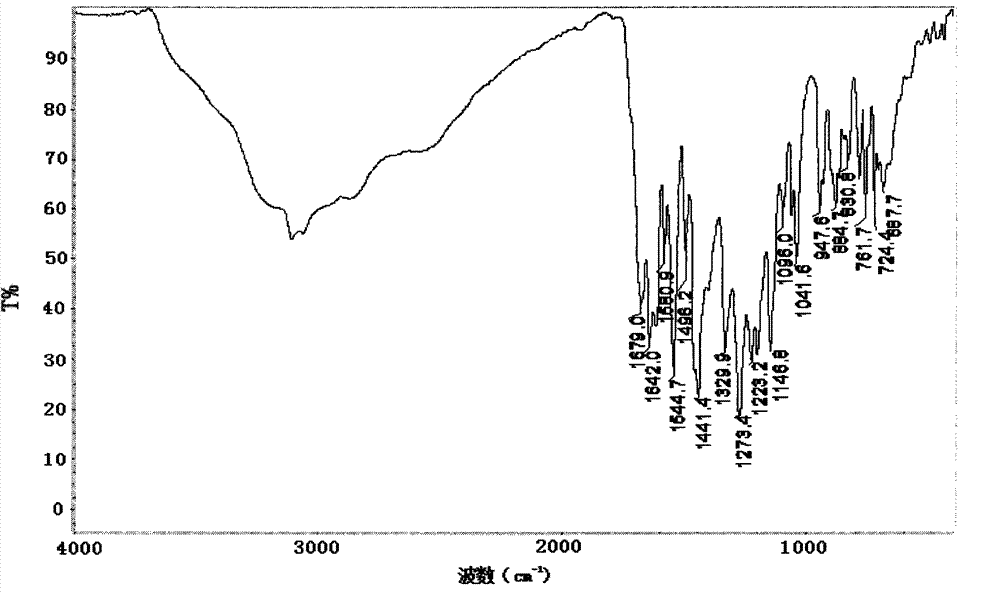

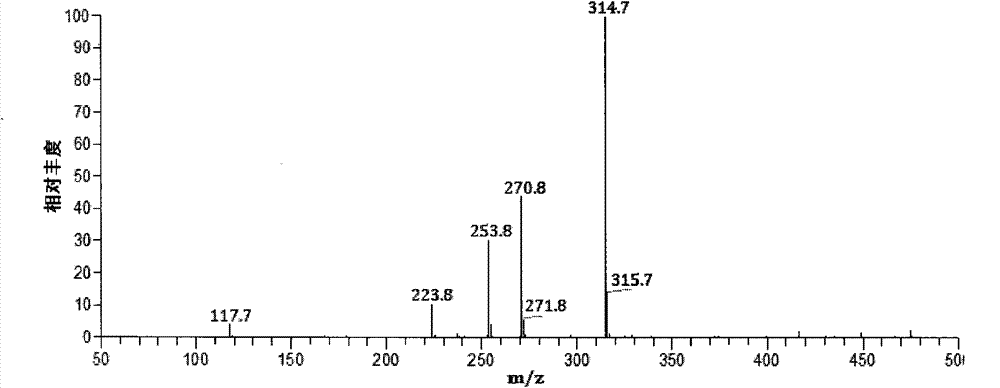

[0056] (1) Synthesis of precursor 2-hydroxyl-4-(5-nitro-6-hydroxybenzoxazol-2-yl)benzoic acid (formula V, HNBA)

[0057] Add 5.50g (0.030mol) of hydroxyterephthalic acid and 100mL of diethylene glycol dimethyl ether to the four-port glass reactor in turn, stir well and add 3.6g (0.0303mol) of SOCl 2 , and start heating to carry out the reaction at 75-80°C for more than 1 hour. After the reaction liquid is clear and transparent, cool it to 50°C, and quickly add 6.20g (0.030mol) of 4-amino-6-nitroisophthalic acid to the reactor. Phenol hydrochloride (ANRHCl), heat up to 105°C, add 7.0g85% PPA (polyphosphoric acid) after condensation reaction for 2h, continue to heat up to reflux for ring closure and dehydration reaction for 3h, cool to room temperature, filter, wash, After drying, 8.27 g of crude HNBA as yellow-brown powder was obtained (crude yield 87.17%, purity 89.23%). The resulting crude product is...

Embodiment 2

[0061] Embodiment 2 Poly 3'-hydroxyl-1', 4'-phenylene-2,6-benzobisoxazole (formula I, ord-PBO-II) and fiber preparation

[0062] (AB type monomer polycondensation method)

[0063] Add 3.2g of P successively into the glass polymerization reactor 2 o 5 and 24.0g83%PPA, heated up to 90°C and stirred for 1h until clear and transparent, that is, the formation of 85.0%PPA 2 o 5 PPA, add 4.11g AB type monomer 2-hydroxyl-4-(5-amino-6-hydroxyl benzoxazol-2-yl) benzoic acid (HABA, 0.0143mol) to make a monomer concentration of 18.0% (wt); heat up to 110°C and stir for 1.5h to dissolve, gradually heat up to 125°C for 45min to appear whole-body fluorescence, react at 125°C for 40min and then gradually heat up to 150°C for 1h, showing silk Then the temperature was raised to 160° C. for 20 minutes to complete the polymerization reaction, and the liquid crystal stock solution of the ordered polymer (ord-PBO-II) was obtained. Directly from the liquid crystal stock solution at 120°C, the f...

Embodiment 3

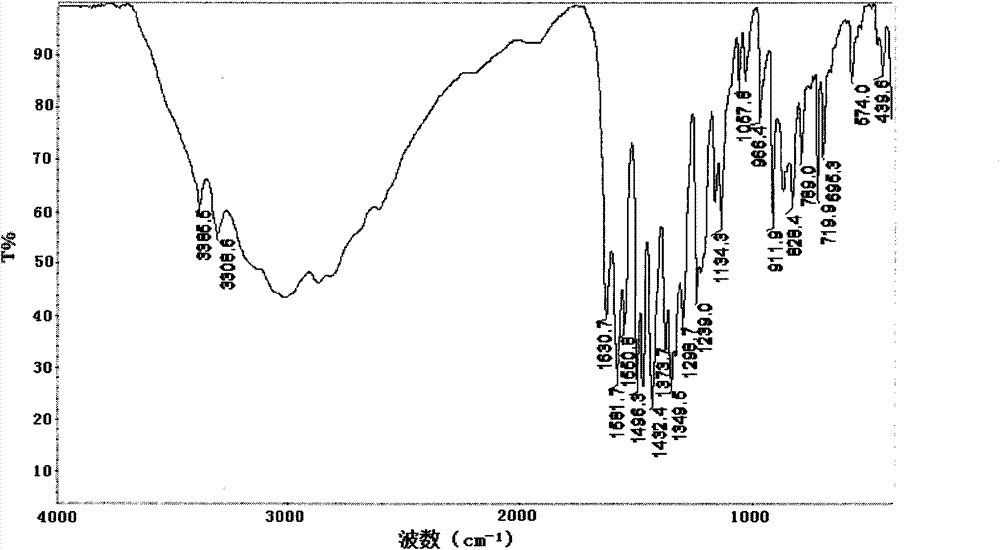

[0064] Example 3 Preparation of key monomer 4,6-diaminoresorcinol hydrochloride (DARHCl)

[0065] Add 41.32g (0.20mol) 4-amino-6-nitroresorcinol hydrochloride (ANR·HCl) and 300g water in the four-hole glass reactor, after stirring and dissolving under the protection of nitrogen, add 80g water dropwise And the dilute alkali solution that 9.17g96%NaOH (0.22mol) is made into, carries out neutralization reaction 10min under the protection of nitrogen, then transfers to acid-resistant autoclave rapidly, and adds 1.0g5%Pd / C catalyst (solid content 50%), After closing the autoclave, successively use N 2 Replace the air 4 times with H 2 replace N 2 After 2 times, control the temperature of 35~45℃, under the hydrogen pressure lower than 1MPa, stir the catalytic hydrogenation for 3h to complete the reaction; 2 After protection and stirring, the filtrate was quickly added to 3.2g SnCl after the catalyst was filtered out. 2 2H 2 In the acidic aqueous solution made of O, 50g36% hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com