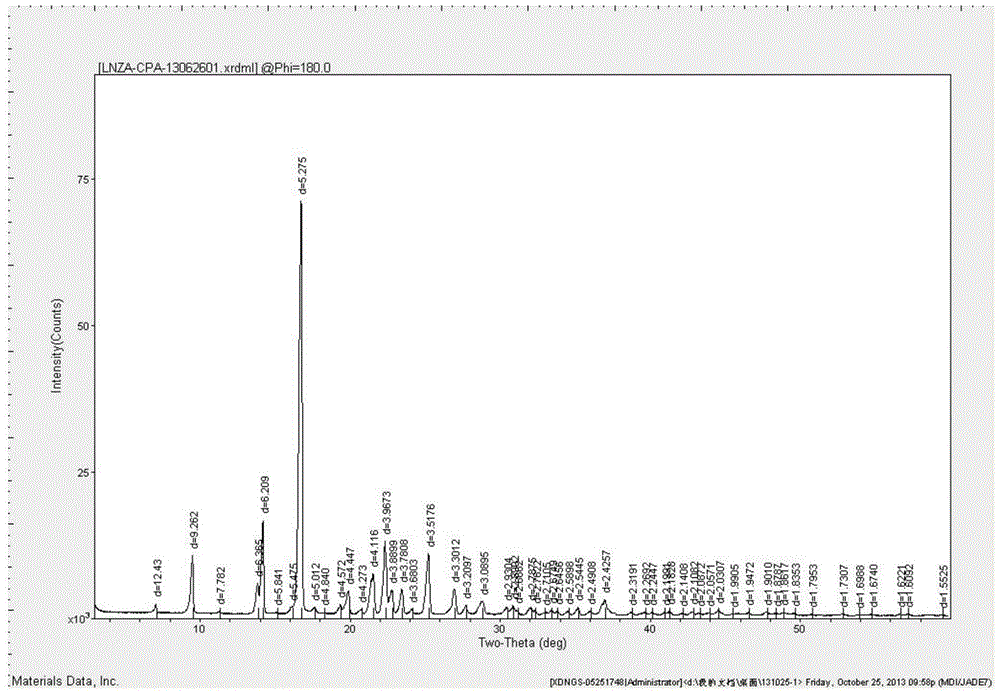

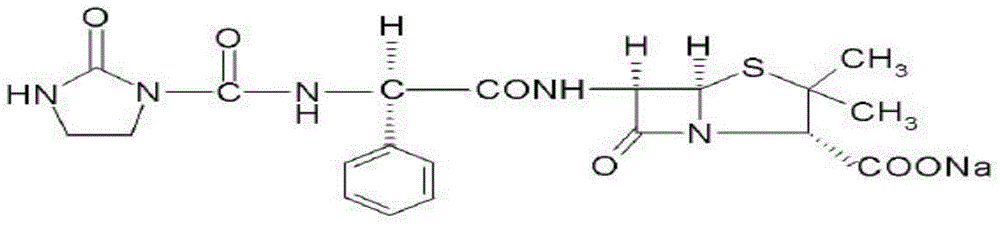

New penicillin crystal preparation and preparation method thereof

A technology of new penicillin and crystal, which is applied in the field of new penicillin crystal preparation and its preparation, can solve the problems of product safety, production safety and safety hazards, poor product stability, and low flash point of acetone, etc. The effect of low residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 1.5kg of commercially available crude penicillin (that is, the purity of new penicillin is not higher than 85%) in a mixed solvent composed of 1.0kg of methanol and 2.0kg of methyl ethyl ketone; stir at room temperature for 1h, then add 100g of activated carbon for adsorption and filter solution, the filtrate was cooled to 0°C, stirred for 1 hour until a large amount of crystals were precipitated; the crystals were washed with a mixed solution of methanol and methyl ethyl ketone (weight ratio 1:2), and dried under reduced pressure at 30°C to obtain the first refined new Penicillin product 1.23kg.

[0030] Add 1.23 kg of neopenicillin obtained above into 30 kg of methyl ethyl ketone solvent (temperature 55° C.), and stir until completely dissolved. Then the solution was filtered through a high-efficiency filter to a crystallization tank, and then the temperature was gradually lowered to 35° C. and concentrated under reduced pressure at this temperature to the re...

Embodiment 2

[0035] Dissolve 1.5kg of commercially available crude penicillin (that is, the purity of new penicillin is not higher than 85%) in a mixed solvent composed of 0.8kg of methanol and 1.6kg of methyl ethyl ketone; stir at room temperature for 1h, then add 100g of activated carbon for adsorption and filter to dissolve liquid, the filtrate was cooled to 2.5°C, and stirred for 1.2h until a large amount of crystals precipitated; the crystals were washed with a mixed solution of methanol and methyl ethyl ketone (1:2 by weight), and dried under reduced pressure at 25°C to obtain the first refined new Penicillin product 1.18kg.

[0036] Add 1.18 kg of neopenicillin obtained above into 25 kg of methyl ethyl ketone solvent (temperature 50° C.), and stir until completely dissolved. Then the solution was filtered through a high-efficiency filter to a crystallization tank, and then the temperature was gradually lowered to 30° C. and concentrated under reduced pressure at this temperature to ...

Embodiment 3

[0039] Dissolve 1.5kg of commercially available crude penicillin (that is, the purity of new penicillin is not higher than 85%) in a mixed solvent composed of 1.5kg of methanol and 3.0kg of methyl ethyl ketone; stir at room temperature for 1h, then add 100g of activated carbon for adsorption and filter to dissolve liquid, the filtrate was cooled to 5°C, and stirred for 1.5h until a large amount of crystals precipitated; the crystals were washed with a mixed solution of methanol and methyl ethyl ketone (1:2 by weight), and dried under reduced pressure at 35°C to obtain the first refined new Penicillin product 1.10kg.

[0040] Add 1.10 kg of neopenicillin obtained above into 35 kg of methyl ethyl ketone solvent (temperature 60° C.), and stir until completely dissolved. Then the solution was filtered through a high-efficiency filter to a crystallization tank, and then the temperature was gradually lowered to 40° C. and concentrated under reduced pressure at this temperature to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com