A polycarboxylate water reducer for prestressed high-strength concrete pipe piles and its application

A technology of high-strength concrete and water-reducing agent, applied in the field of concrete admixtures, can solve the problems of high requirements, complex process, unfavorable industrial production, etc., and achieve the effects of low air entrainment, abundant sources, and not easy to hang slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

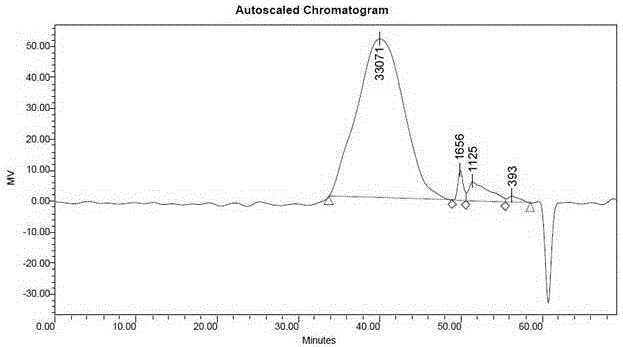

Image

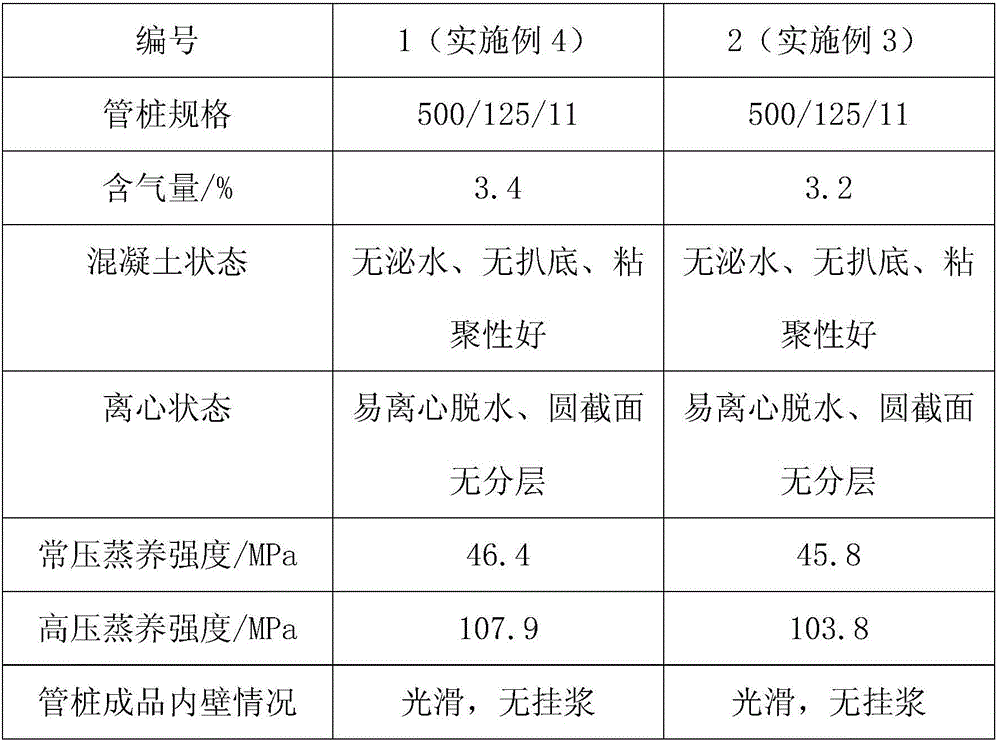

Examples

Embodiment 1

[0027] Take 59g of methallyl polyoxyethylene ether 2400 (HPEG2400), 30g of isoprenol polyoxyethylene ether 2400 (TPEG2400), 8.9g of acrylic acid, 0.6g of sodium methacryl sulfonate, N-methylol propylene Amide 0.45g, mercaptopropionic acid 0.2g, mass fraction of 30% hydrogen peroxide 0.65g, vitamin C 0.2g.

[0028] Add 70g of soft water, 0.65g of 30% hydrogen peroxide, 59g of HPEG2400, and 30g of TPEG2400 into a four-neck flask equipped with a thermometer, a speed-adjustable stirrer, a reflux condenser, and a dropping device, then stir and heat to about 80°C. Next, add dropwise an aqueous solution composed of 8.9g of acrylic acid, 0.6g of sodium methacrylsulfonate, 0.45g of N-methylolacrylamide, and 0.2g of mercaptopropionic acid. g of vitamin C aqueous solution, drop it in 210 minutes, keep it warm for 90 minutes, then cool down to 50°C, and then adjust the pH value to 7 with a mass fraction of 30% sodium hydroxide solution to obtain 40% of the required polycarboxylate superpl...

Embodiment 2

[0030] Take methallyl polyoxyethylene ether 2400 (HPEG2400) 59g, prenol polyoxyethylene ether 2400 (TPEG2400) 30g, acrylic acid 4.5g, maleic anhydride 4.4g, sodium methacrylate sulfonate 0.7g, N-methylolacrylamide 0.35g, mercaptopropionic acid 0.2g, 30% hydrogen peroxide 0.65g, vitamin C 0.2g.

[0031] Add 75g of soft water, 0.65g of 30% hydrogen peroxide, 59g of HPEG2400, and 30g of TPEG2400 into a four-necked flask equipped with a thermometer, a speed-adjustable stirrer, a reflux condenser, and a dropping device, then stir and heat to about 80°C. Next, add dropwise an aqueous solution composed of 4.5g of acrylic acid, 4.4g of maleic anhydride, 0.7g of sodium methacrylate, 0.35g of N-methylolacrylamide, and 0.2g of mercaptopropionic acid, and drop them in 180 minutes. At the same time, 0.2g of vitamin C aqueous solution was added dropwise for 210 minutes, kept for 90 minutes, then cooled to 50°C, and then adjusted to pH 7 with 30% sodium hydroxide solution to obtain 40% of th...

Embodiment 3

[0033] Take methallyl polyoxyethylene ether 2400 (HPEG2400) 59g, prenol polyoxyethylene ether 2400 (TPEG2400) 30g, acrylic acid 5.9g, maleic anhydride 3g, sodium methacrylate sulfonate 0.7g, N -Methylolacrylamide 0.35g, mercaptopropionic acid 0.2g, 30% hydrogen peroxide 0.65g, vitamin C 0.2g.

[0034] Add 75g of soft water, 0.65g of 30% hydrogen peroxide, 59g of HPEG2400, and 30g of TPEG2400 into a four-necked flask equipped with a thermometer, a speed-adjustable stirrer, a reflux condenser, and a dropping device, then stir and heat to about 80°C. Next, add dropwise an aqueous solution composed of 8.9g of acrylic acid, 4.4g of maleic anhydride, 0.6g of sodium methacrylate, 0.45g of N-methylol acrylamide, and 0.2g of mercaptopropionic acid. After dropping, add 0.2g vitamin C aqueous solution dropwise at the same time, finish dropping for 220 minutes, keep warm for 90 minutes, then cool down to 50°C, and then adjust the pH value to 7 with a mass fraction of 30% sodium hydroxide so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com