Antibacterial medical dressing film carrying nano-silver and cellulose nanocrystalline hybrid materials and preparation method thereof

A hybrid material and cellulose technology, applied in the field of new multifunctional fully biodegradable composite membrane and its preparation, can solve the problems of difficulty in blocking bacterial re-infection, lack of effective combination of nano silver and cellulose nanocrystals, etc. Biocompatibility and cytocompatibility, increase synergistic enhancement effect, increase reproduction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

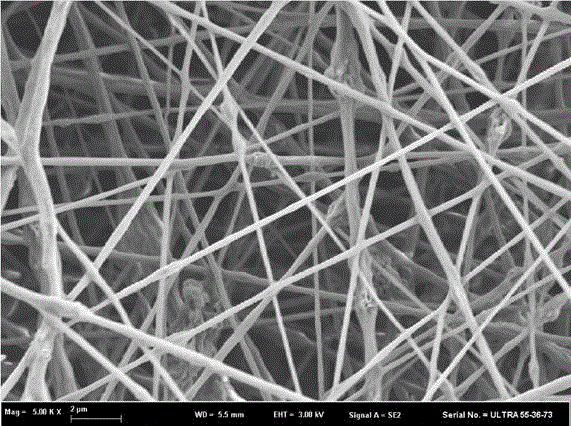

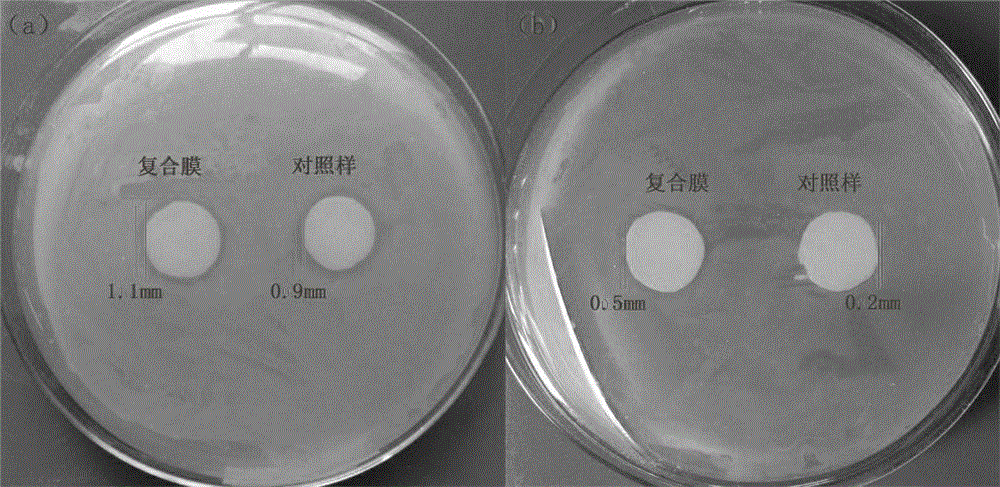

[0036]Add the hemp fiber into the formic acid-hydrochloric acid solution and react at 48°C for 12 hours. The solid-to-liquid ratio of microcrystalline cellulose and the mixed acid aqueous solution is 1:60 g / mL. mol / L) volume ratio is 6:1, after the reaction is finished, the reaction product is washed with deionized water until neutral, and the aldylated cellulose nanocrystals can be obtained; then the aldylated cellulose nanocrystals are added to In a 0.03 mol / L silver nitrate solution, react at 85°C for 20 min, in which the solid-to-liquid ratio of the aldylated cellulose nanocrystals to the silver nitrate solution is 1:100 g / mL. Dilute the reaction product with water, centrifuge several times to remove the inorganic ions, and then vacuum-dry the dispersion to obtain the nanosilver-cellulose nanocrystalline hybrid material;

[0037] Add nano-silver-cellulose nanocrystalline hybrid material and polyhydroxybutyrate valerate (PHBV) into chloroform, raise the temperature to 70°C,...

Embodiment 2

[0041] Add microcrystalline cellulose into formic acid-hydrochloric acid solution and react at 70°C for 2 h. The solid-to-liquid ratio of hemp fiber to mixed acid aqueous solution is 1:50 g / mL. Formic acid (5 mol / L) and hydrochloric acid ( 7 mol / L) with a volume ratio of 8:1. After the reaction, the reaction product was washed with deionized water until neutral to obtain aldylated cellulose nanocrystals; then the aldylated cellulose nanocrystals Add 0.3 mol / L silver nitrate solution, react at 80°C for 35 min, wherein the solid-liquid ratio of cellulose nanocrystals and silver ammonia solution is 1:220 g / mL, after the reaction is finished, use Dilute the reaction product with ionized water, centrifuge several times to remove the inorganic ions, and then vacuum-dry the dispersion to obtain the nanosilver-cellulose nanocrystalline hybrid material;

[0042] Add the nanosilver-cellulose nanocrystalline hybrid material to the N,N-dimethylformamide solution of polyhydroxybutyrate val...

Embodiment 3

[0046] The hemp fiber was added into the formic acid-hydrochloric acid solution and reacted at 40°C for 8 h. The solid-liquid ratio of the bamboo fiber to the mixed acid aqueous solution was 1:60 g / mL, and the formic acid (6 mol / L) and hydrochloric acid (4 mol / L) volume ratio is 8:1, after the reaction is finished, the reaction product is washed with deionized water to neutrality, and aldehyde-based cellulose nanocrystals can be obtained; then add 0.08 mol / L silver-ammonia solution, reacted at 78 °C for 51 min, and the solid-liquid ratio of cellulose nanocrystals and silver-ammonia solution was 1:150 g / mL. Dilute the reaction product, centrifuge several times to remove inorganic ions, and then vacuum-dry the dispersion to obtain nanosilver-cellulose nanocrystalline hybrid material;

[0047] Add the nano-silver-cellulose nanocrystalline hybrid material to the ethyl acetate solution of polycaprolactone (PCL), raise the temperature to 48°C, and stir thoroughly to obtain a transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com