Method for quantitatively detecting thiocyanate in milk and milk products

A quantitative detection and thiocyanate technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of unfavorable use and promotion of small enterprises, low accuracy of thiocyanate, inconvenient to carry and rapid detection, etc., and achieve short detection time , high accuracy and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 measures the accuracy and repeatability experiment of sample

[0049] (1) Sample pretreatment

[0050] Weigh 6 parts of 2.5 grams of certain milk samples into 25mL colorimetric tubes, dilute to 10mL with distilled water, shake well, add 0.5mL sodium thiocyanate reagent A, dilute to 25mL with distilled water, cover, mix well, and let stand Filter after 5 minutes, and the filtrate is set aside;

[0051] Weigh 6 parts of 1.00 g pulverized milk powder samples into 25 mL colorimetric tubes, dilute to 10 mL with distilled water, cover and stopper, mix well, add 0.5 mL of sodium thiocyanate reagent A, dilute to 25 mL with distilled water, cover and stopper , mix well, filter after standing for 5 minutes, and set aside the filtrate;

[0052] (2) Determination of samples

[0053] ① Sample solution: Take 1mL filtrate in a 10mL colorimetric tube, add 4mL distilled water, shake well, add 0.5mL sodium thiocyanate reagent B, shake well, add 5 drops (0.25mL) sodium thi...

Embodiment 2

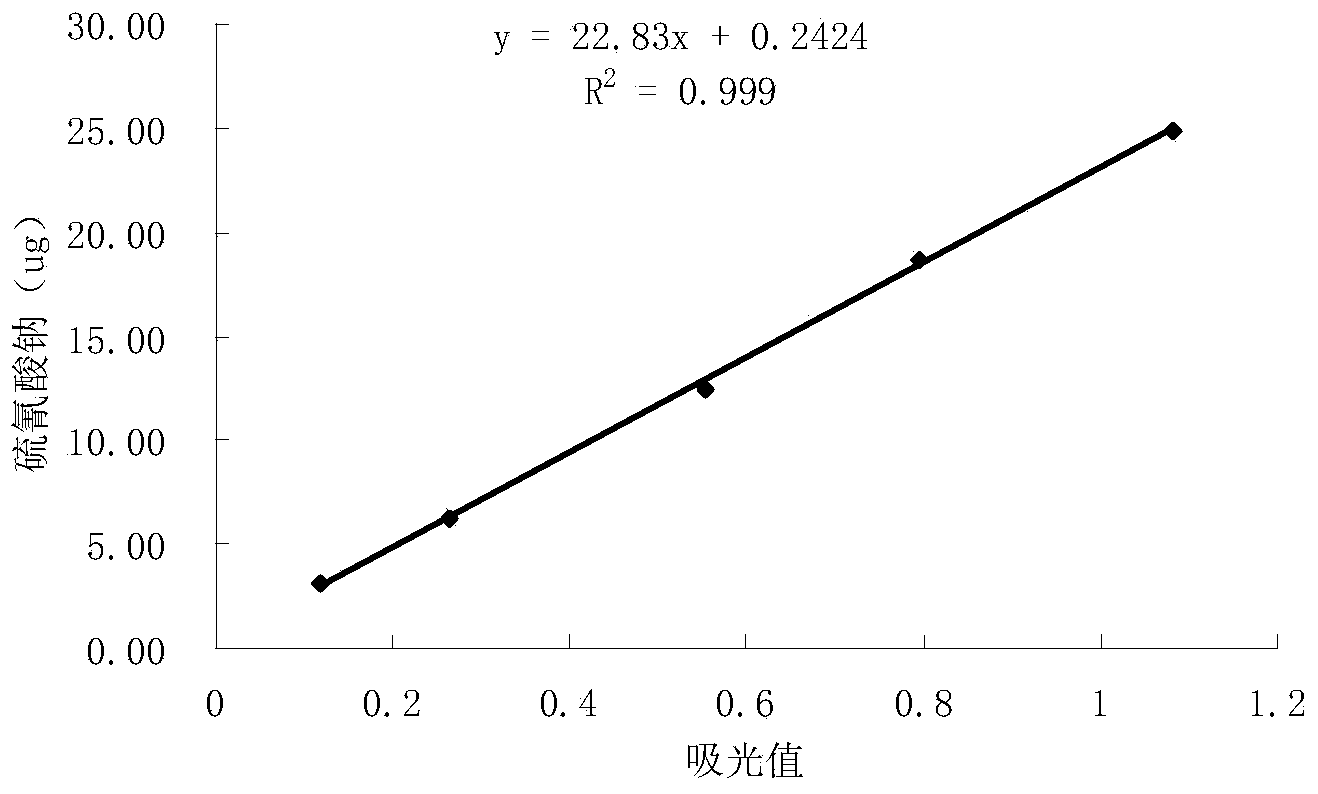

[0063] Accuracy and repeatability experiment when embodiment 2 measures standard solution

[0064] When determining the accuracy, three standard solutions with concentrations of 5.968ug, 14.920ug and 23.872ug were selected, and the test results are shown in Table 3. The accuracies were 1.37%, 4.95%, 2.23%, respectively, and the RSDs were 4.2%, 3.5%, 2.4%, indicating that the accuracy and repeatability of the method were good.

[0065] Table 3 Sodium thiocyanate accuracy

[0066]

[0067]

Embodiment 3

[0068] Embodiment 3 standard addition recovery rate experiment

[0069] The milk powder and milk were subjected to the spike recovery experiment, and the test results are shown in Table 4 and Table 5. It can be seen from the table that the recovery rate of the sample addition is between 90.2% and 97.7%, which meets the requirement of recovery rate of 80% to 120%, indicating that the method has high accuracy.

[0070]Table 4 The test results of milk powder spiked recovery rate

[0071]

[0072] Table 5 The test results of milk spiked recovery rate

[0073]

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com