Silicon-containing polyimide coating adhesive with high adhesion and preparation method of silicon-containing polyimide coating adhesive

A polyimide coating, high-adhesion technology, applied in the field of microelectronic information, can solve the problems of high cost, lack of extensiveness, large amount of double-ended aminotetramethylsiloxane added, etc., and achieve excellent adhesion , the effect of product cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

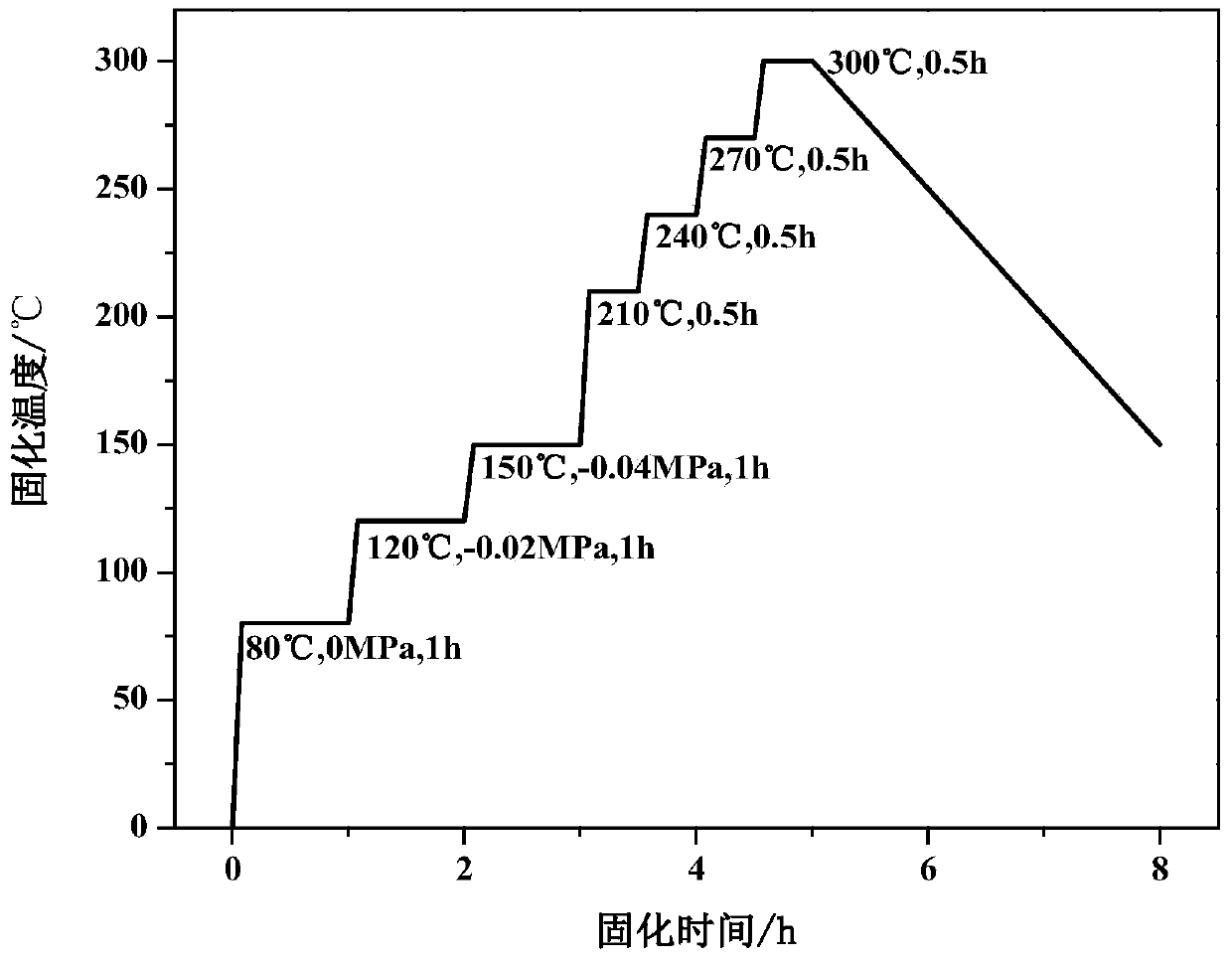

[0027] Dissolve 7.7 parts of 4,4'-diaminodiphenyl ether in 55.5 parts of N-methylpyrrolidone at 10-30°C, and add 0.3 parts of 1,3-bis(3-aminopropyl)-1 , 1,3,3-Tetramethyldisiloxane. Then add 0.6 parts of 1,3-bis(3,4-dicarboxyphenyl)-1,1,3,3-tetramethyldisiloxane dianhydride and 0.4 parts of A mixture of pyromellitic dianhydride, 2 parts of 3,3',4,4'-benzophenone tetracarboxylic dianhydride and 9.7 parts of 3,3',4,4'-diphenylmethyl ether tetracarboxylic dianhydride For copolymerization, continue to add 23.8 parts of solvent, and carry out the reaction for 3 hours under vigorous stirring, and the obtained yellow homogeneous viscous liquid is silicon-containing polyimide coating glue. Apply coating glue to aluminum, copper, nickel, single crystal silicon wafer, glass or Al 2 o 3 , AlN, BeO, SiC and Si 3N 4 The surface of the ceramic material is placed in a vacuum oven at 80°C, 0MPa, 120°C, -0.02MPa, 150°C, and -0.04MPa for 1 hour, and then placed in a muffle furnace at 210°C...

Embodiment 2

[0029] Dissolve 8.4 parts of 4,4'-diaminodiphenyl ether in 54 parts of N-methylpyrrolidone at 10-30°C, and add 0.3 parts of 1,3-bis(3-aminopropyl)-1 , 1,3,3-tetramethyldisiloxane and 0.3 parts of 1,3-bis(3-aminobutyl)-1,1,3,3-tetramethyldisiloxane. Then add 0.5 parts of 1,3-bis(3,4-dicarboxyphenyl)-1,1,3,3-tetramethyldisiloxane dianhydride and 2.2 parts of 3 , 3',4,4'-Benzophenone tetra-acid dianhydride and 11.2 parts of 3,3',4,4'-Diphenylmethyl ether tetra-acid dianhydride are copolymerized, then add 23.1 parts of solvent, violent The reaction was carried out for 6 hours under stirring, and the obtained yellow homogeneous viscous liquid was silicon-containing polyimide coating glue. Apply coating glue to aluminum, copper, nickel, single crystal silicon wafer, glass or Al 2 o 3 , AlN, BeO, SiC and Si 3 N 4 Etc ceramic material surface, the heat treatment step is the same as that of Example 1, to obtain silicon-containing polyimide composite boards with different substrate...

Embodiment 3

[0031] Dissolve 8 parts of 4,4'-diaminodiphenyl ether in 52.3 parts of N,N-dimethylacetamide at 10-30°C, add 0.3 parts of 1,3-bis(3-aminopropyl base)-1,1,3,3-tetramethyldisiloxane and 0.3 parts of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethylpolysiloxane ( n=4). Then, 0.3 parts of 1,3-bis(3,4-dicarboxyphenyl)-1,1,3,3-tetramethyldisiloxane dianhydride and 16.4 parts of Polymerize 3,3',4,4'-triphenylene ether tetraacid dianhydride, then add 22.4 parts of solvent, and react under vigorous stirring for 8 hours, the obtained yellow homogeneous viscous liquid is silicon-containing polyimide Coating glue. Apply coating glue to aluminum, copper, nickel, single crystal silicon wafer, glass or Al 2 o 3 , AlN, BeO, SiC and Si 3 N 4 Etc ceramic material surface, the heat treatment step is the same as that of Example 1, to obtain silicon-containing polyimide composite boards with different substrates. After the adhesion test, the adhesion between the coating and different substrates ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Onset decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com