A kind of water-based polyurethane adhesive with high solid content for shoes and preparation method thereof

A water-based polyurethane, high solid content technology, applied in the preparation of sulfonates, organic chemistry, etc., can solve the problems of difficult to control reaction speed, difficult to increase solid content, same activity, etc., to achieve easier control of reaction speed, short drying time, The effect of fast solvent evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

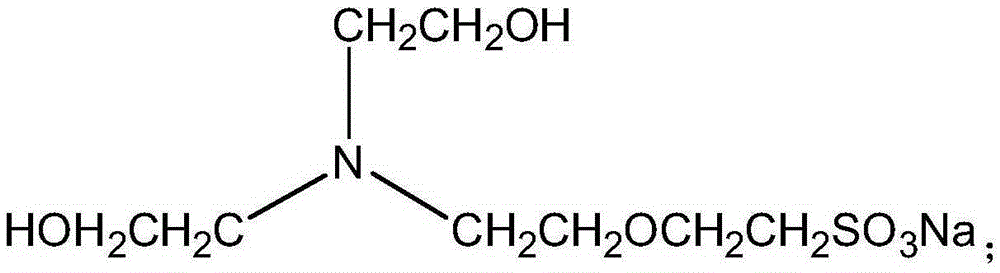

[0045] The dihydric alcohol containing sulfonic acid group used in the embodiment of the present invention, preparation method is as follows:

[0046] In parts by weight, the triethanolamine of 149 parts by weight and sodium isethionate powder of 178 parts by weight are uniformly dissolved in 200 parts by weight of n-decane, and then added to a four-wheel tank equipped with an electric mixer and a serpentine condensing reflux pipe. In the flask, heat up to 210-230°C, add 23 parts by weight of sodium metal, reflux at 220-240°C for 3-4 hours, cool to room temperature, add 50 parts by weight of absolute ethanol to dissolve and filter, and vacuum at -0.1MPa Degree, 140~160 DEG C, vacuum distillation for 2 hours to remove n-decane, absolute ethanol and water, to obtain diols containing sulfonic acid groups, the structural formula of the obtained dibasic alcohols containing sulfonic acid groups is as follows:

[0047]

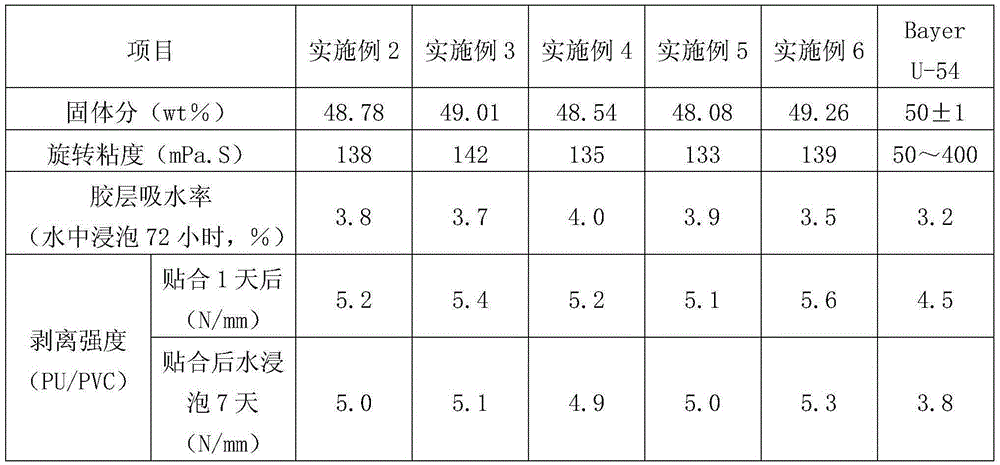

Embodiment 2

[0049]A water-based polyurethane adhesive with high solid content for shoes, the formula composition and dosage are shown in Table 1, and the specific preparation steps are as follows:

[0050] Add the formulated amount of poly(1,4-butylene adipate) and diol containing sulfonic acid groups into the polymerization reactor equipped with a digital display electric stirrer and a thermometer, raise the temperature to 120°C, and depressurize Distill to remove water, keep warm for 2 hours, cool down to 60-70°C after water removal is complete; add catalysts dibutyltin dilaurate and isophorone diisocyanate to the polymerization reactor, heat up to 85°C, and stir for 3.5 h; then lower the temperature to 70°C, add methyl ethyl ketone, stir for 10 minutes, add 1,4-butanediol, and stir for 3 hours; transfer the reaction product in the polymerization reactor to the dispersion barrel, and set the speed of the high-speed shear mixer to 4500rpm , add deionized water to the dispersion tank for ...

Embodiment 3

[0054] A water-based polyurethane adhesive with high solid content for shoes, the formula composition and dosage are shown in Table 2, and the specific preparation steps are as follows:

[0055] Add the formulated amount of poly-1,4-butylene adipate and diol containing sulfonic acid groups into the polymerization reactor equipped with a digital display electric stirrer and a thermometer, raise the temperature to 125°C, and depressurize Distill to remove water, keep warm for 2 hours, cool down to 60-70°C after the end of water removal; add catalysts dibutyltin dilaurate and isophorone diisocyanate to the polymerization reactor, heat up to 80°C, and stir for 2.5 h; then lower the temperature to 75°C, add butanone, stir for 10 minutes, then add 1,4-butanediol, and stir for 2.5 hours; transfer the reaction product in the polymerization reactor to the dispersion barrel, and set the speed of the high-speed shear mixer 5000rpm, add deionized water into the dispersion tank for shear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com