Sedimentation-reverse perfusion-flow coupling method for preparing DHA-rich oil and its special cell sedimentation tank

A settling tank, cell technology, applied in microorganism-based methods, biochemical equipment and methods, specific-purpose bioreactors/fermenters, etc., can solve the problem of unstable DHA yield, reduced DHA yield, and reduced oil quality and other problems to achieve the effect of avoiding cell loss, avoiding stasis and senescence, maintaining activity and accumulation of fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of oil rich in DHA by conventional cell settling tank sedimentation-reverse perfusion-discharge coupling

[0036] Preservation and cultivation of microalgae: Schizochytrium sp. CGMCC No. 7693 in this example was submitted to the General Microorganism Center of China Committee for the Collection of Microorganisms (CGMCC for short) for preservation on June 9, 2013. The composition of the solid preservation, expansion and fermentation medium of algae species is: glucose 10g / L, tryptone 1g / L, yeast extract 3g / L, sodium chloride 15g / L, magnesium sulfate 2g / L, potassium dihydrogen phosphate 0.5g / L, potassium chloride 1g / L, calcium chloride 0.5g / L, ammonium sulfate 0.2g / L, sodium bicarbonate 0.1g / L, boric acid 34.2mg / L, edetate disodium 40mg / L L, manganese chloride 2.5mg / L, ferric chloride 2.5mg / L, cyanocobalamin 0.1mg / L, zinc chloride 2mg / L, cobalt chloride 0.5mg / L, copper sulfate 0.02mg / L, pH = 6, add agar 15g / L to the solid medium. After the medium is prepared...

Embodiment 2

[0039] Preparation of DHA-enriched oil in a 10-liter fermenter using sedimentation-backflow-flow coupling

[0040] In the present embodiment, carry out the activation and expansion culture of bacterial classification by the method identical with embodiment 1, prepare 9L fermentation culture and be based on in 10L fermenter, the composition of culture medium is: glucose 20g / L, tryptone 1g / L, Yeast extract 5g / L, sodium chloride 25g / L, magnesium sulfate 1g / L, potassium dihydrogen phosphate 5g / L, potassium chloride 0.1g / L, calcium chloride 0.3g / L, ammonium sulfate 1g / L, carbonic acid Sodium Hydrogen 0.5g / L, Boric Acid 25mg / L, Disodium EDTA 50mg / L, Manganese Chloride 0.5mg / L, Ferric Chloride 5mg / L, Cyanocobalamin 0.2mg / L Zinc Chloride 1.5mg / L, cobalt chloride 0.05mg / L, copper sulfate 0.01mg / L, pH=6.5, add agar 15g / L to the solid medium. Cool after sterilization, inoculate into a fermenter according to 5% inoculation amount, the fermentation temperature is 20-30 DEG C, the pH is co...

Embodiment 3

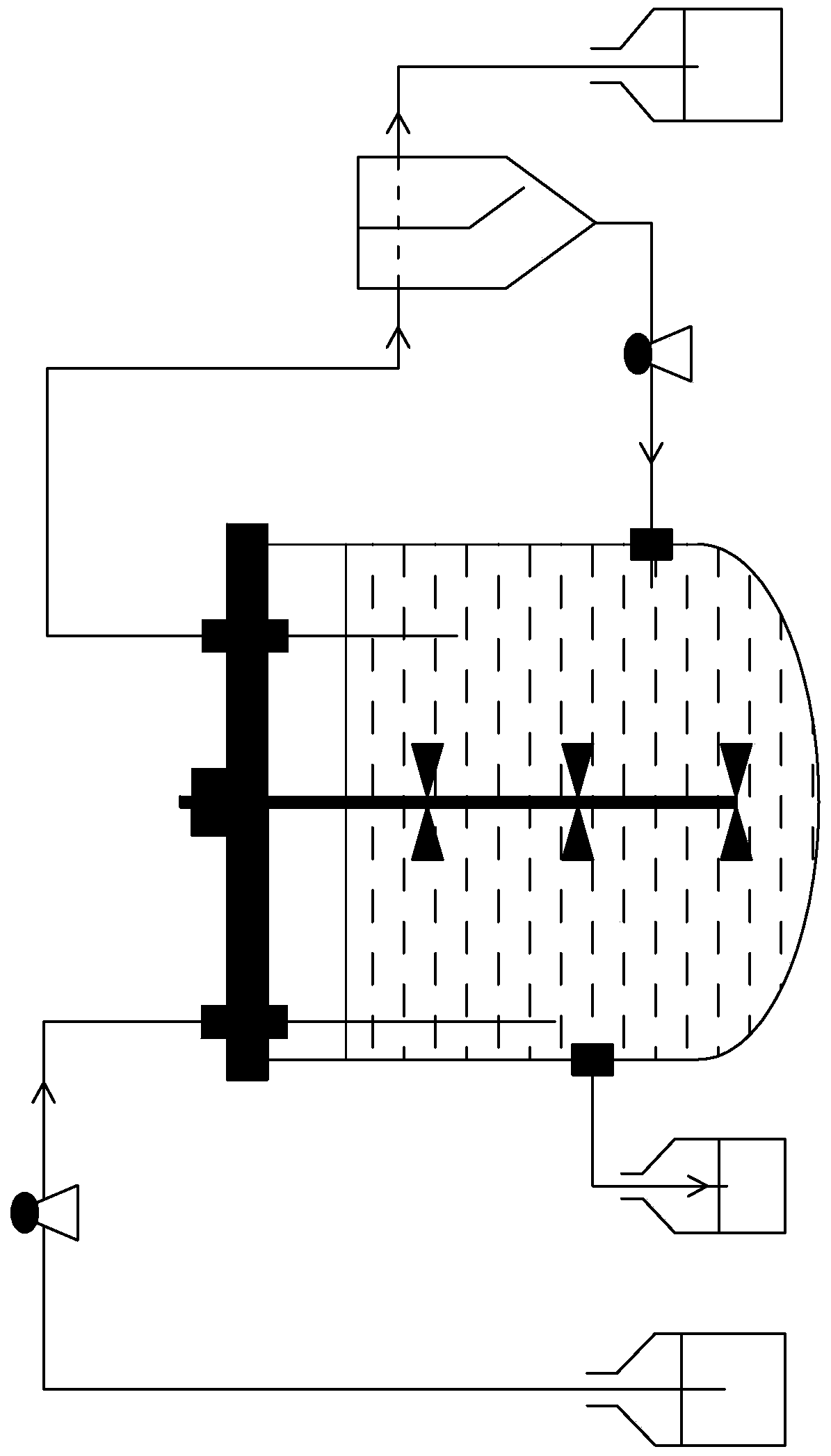

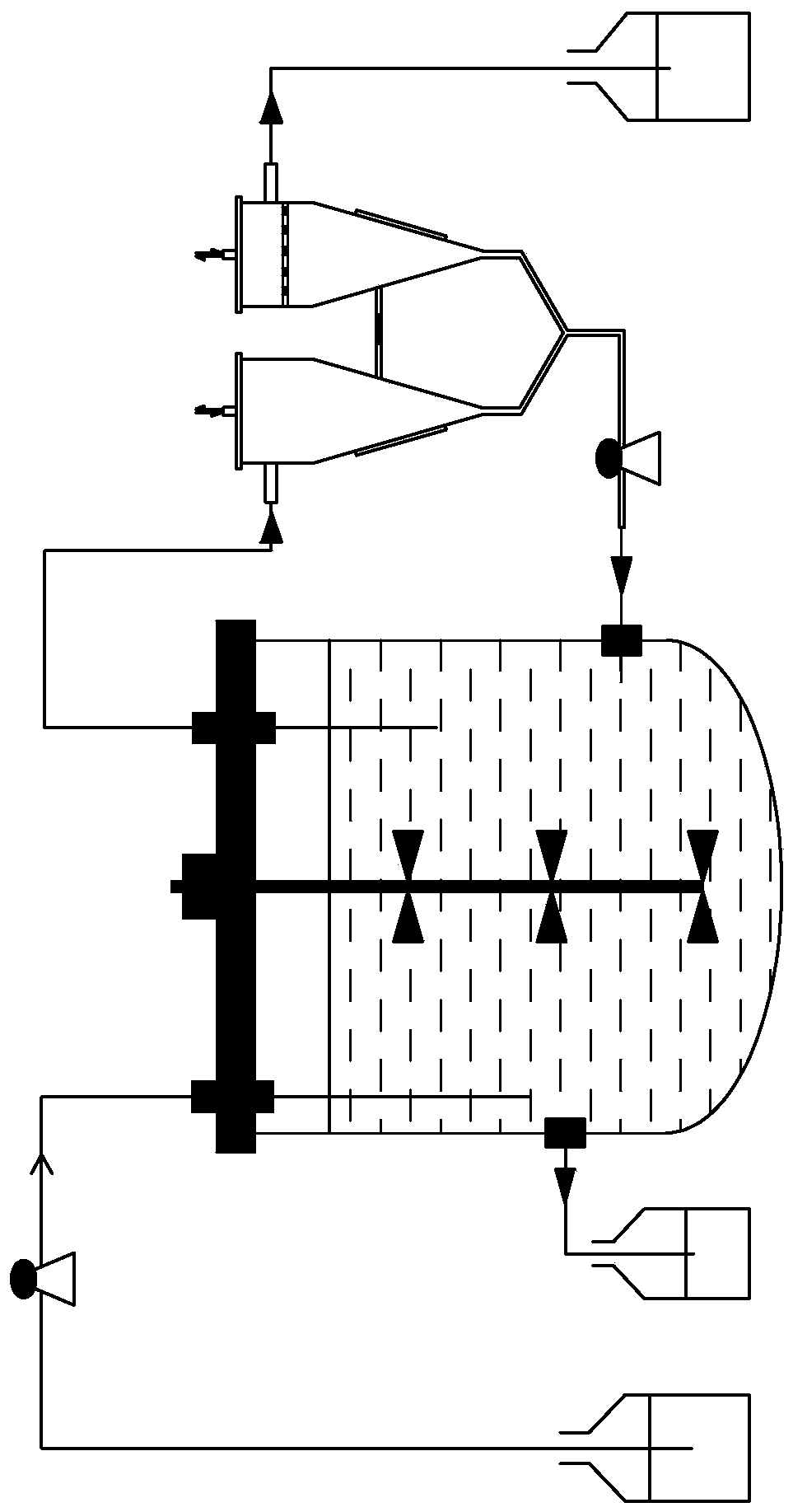

[0042] Preparation of oil rich in DHA by coupling cell sedimentation-reverse perfusion-discharge in a special cell sedimentation tank

[0043] This embodiment provides an improved settling device for intercepting easily-settled microbial cells, so as to more effectively complete the cell concentration reflux in the process of settling-counterperfusion microalgae cell culture. What needs to be solved is the problem that the cells are not easy to settle due to the disturbance of the fermentation liquid in the ordinary settling tank, and the problems that the hollow fiber membrane is easy to be blocked, difficult to clean, and has a short life.

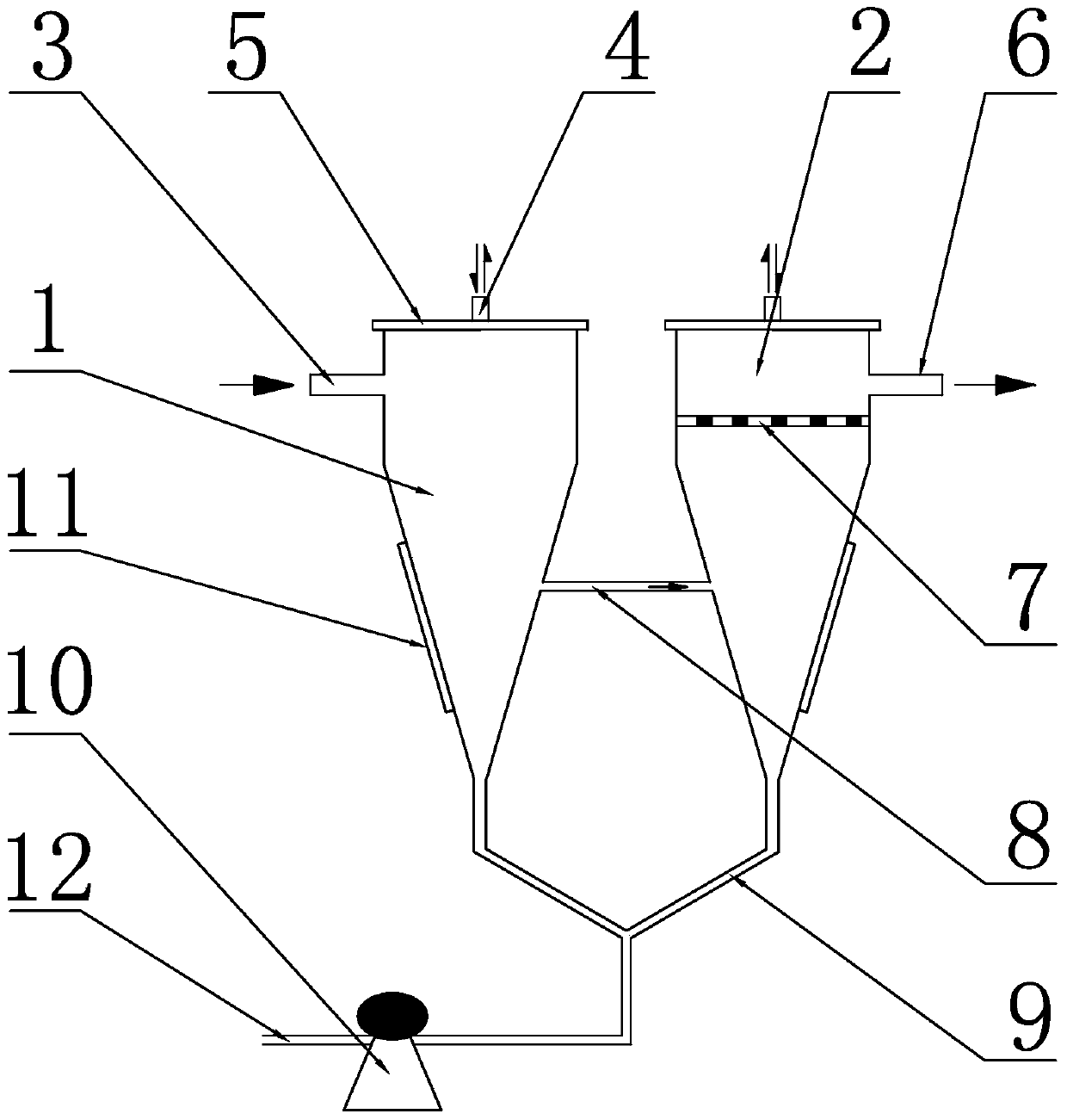

[0044] The settling tank specifically includes (as image 3 ): special settling tank, including two first-level settling tank 1 and second-level settling tank 2 arranged at intervals and conical in shape, and a cover 5 arranged on the first-level settling tank 1 and second-level settling tank 2, The opening 4 opened on the cover 5 is op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com