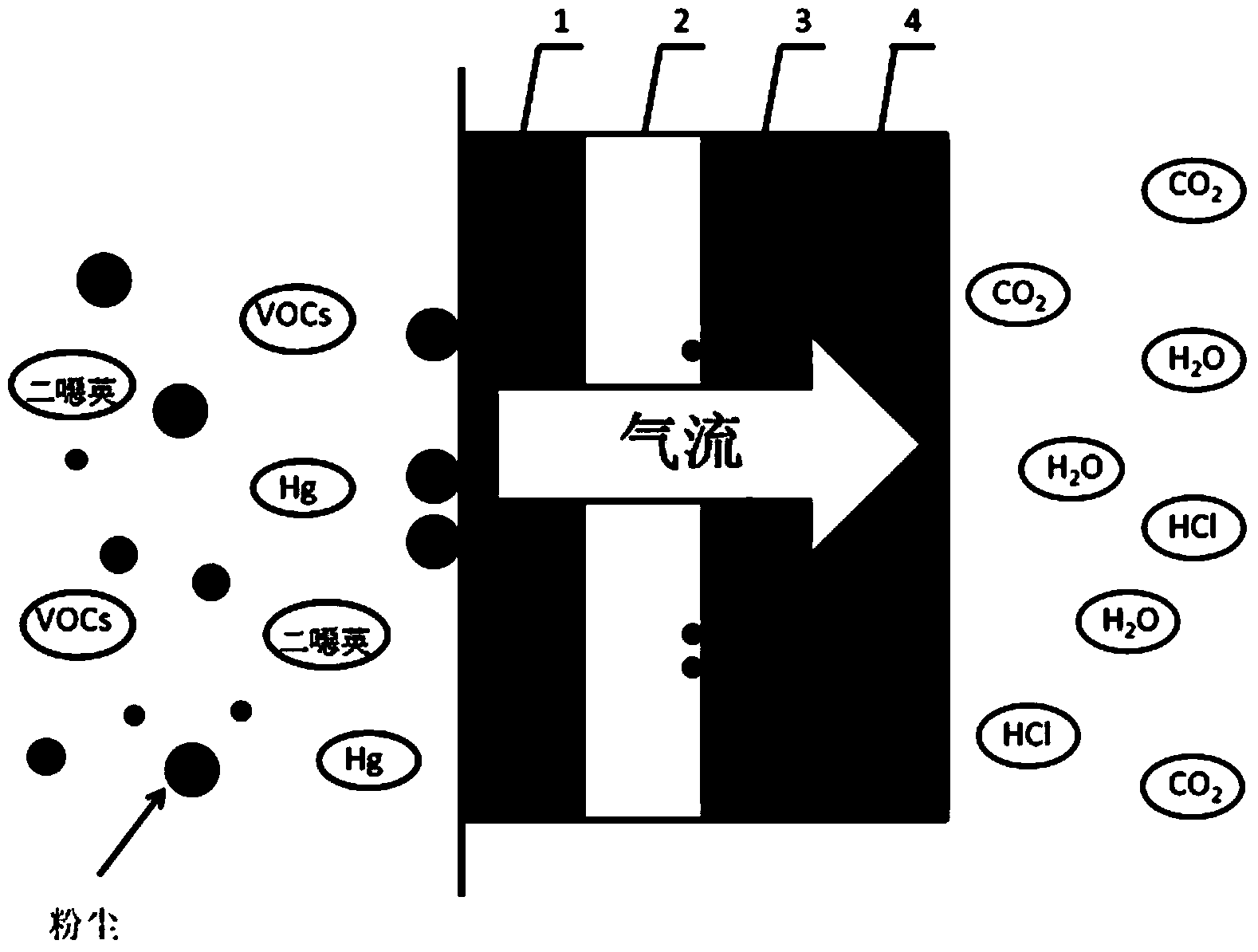

Composite nanometer filter material with catalytic function as well as preparation method and application of composite nanometer filter material

A composite and nanofiltration technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problem of small contact area between catalyst and gas, low porosity of fibrous layer, lack of catalytic effect, etc. problems, to achieve good application prospects, high removal efficiency, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

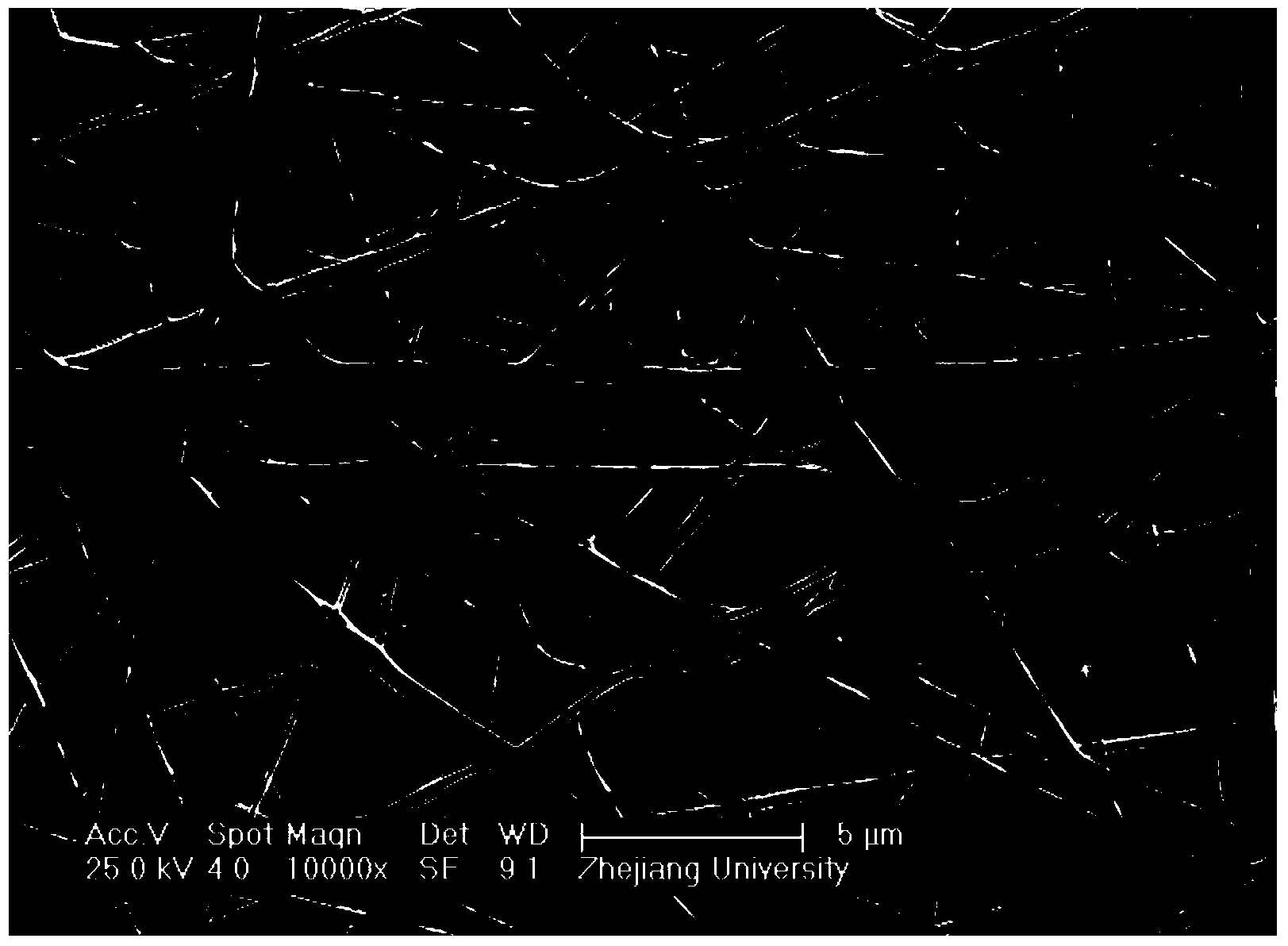

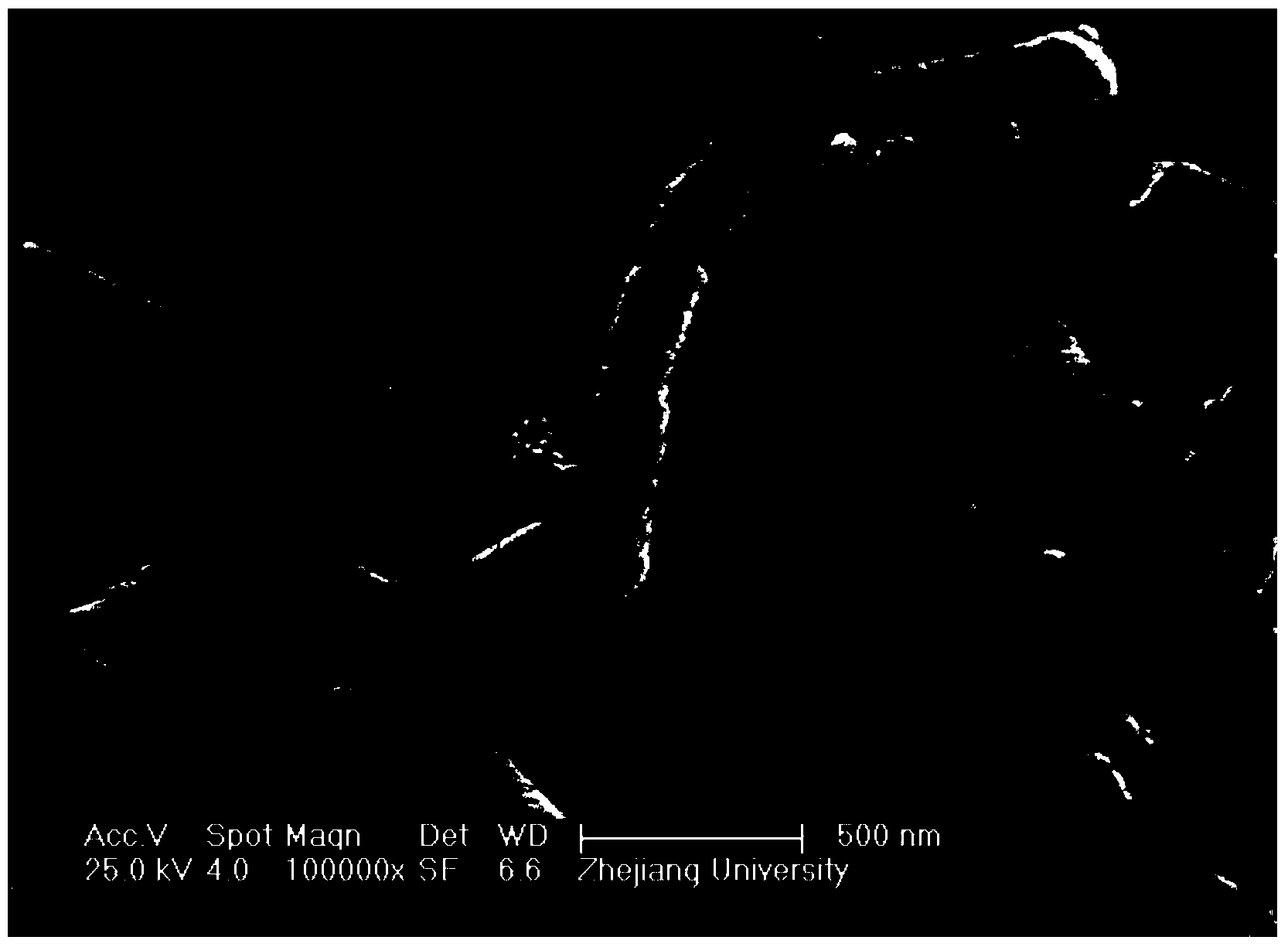

[0041] Preparation of catalytic filter layer

[0042] (1) Preparation of nanofibers by electrospinning

[0043] Take PVP (molar mass 45,000-55,000g / mol) and add it to absolute ethanol, stir magnetically for 30 minutes until PVP is completely dissolved, add tetrabutyl titanate and glacial acetic acid to make a Ti precursor solution, and stir magnetically at room temperature for 18 hours to obtain the precursor Precursor solution; take 9mL precursor solution with a plastic syringe, fix it at a position 15cm away from the center of the drum, and wrap aluminum foil on the drum as a receiving device for nanofibers; apply a high voltage power supply of 15kV to the stainless steel needle, rotate the drum at 50r / min, and inject the syringe at a speed of 1mL / min, get TiO 2 Nanofibers;

[0044] (2) Calcination to form nanofiber carrier

[0045] After spinning, remove the aluminum foil and place it at room temperature for 12 hours to fully hydrolyze the nanofibers; put the placed alum...

Embodiment 2

[0049] Preparation of catalytic filter layer

[0050] (1) Preparation of nanofibers by electrospinning

[0051] Take PVP (molar mass 45000-55000g / mol) and add it to absolute ethanol, stir magnetically for 30 minutes until PVP is completely dissolved, add tetrabutyl titanate, ethyl orthosilicate and glacial acetic acid to make Si / Ti molar ratio 1 : 9 precursor solution, magnetically stirred for 18h at room temperature; 9mL precursor solution was taken with a plastic syringe, fixed at a position 15cm away from the center of the drum, and aluminum foil was wrapped on the drum as a receiving device for nanofibers; a high voltage power supply of 15kV was added at the stainless steel needle, The rotating speed of the drum is 50r / min, the perfusion speed of the syringe is 1mL / min, SiO 2 -TiO 2 Composite nanofibers;

[0052] (2) Calcination to form nanofiber carrier

[0053] After spinning, remove the aluminum foil and place it at room temperature for 12 hours to fully hydrolyze t...

Embodiment 3

[0057] Preparation of catalytic filter layer

[0058] (1) Preparation of nanofibers by electrospinning

[0059] Take PVP (molar mass 45000-55000g / mol) and add it to absolute ethanol, stir magnetically for 30 minutes until PVP is completely dissolved, add tetrabutyl titanate, ethyl orthosilicate and glacial acetic acid to make Si / Ti molar ratio 1 :4 precursor solution, magnetically stirred at room temperature for 18h; 9mL precursor solution was taken with a plastic syringe, fixed at a position 15cm away from the center of the drum, and aluminum foil was wrapped on the drum as a receiving device for nanofibers; The rotating speed of the drum is 50r / min, the perfusion speed of the syringe is 1mL / min, SiO 2 -TiO 2 Composite nanofibers;

[0060] (2) Calcination to form nanofiber carrier

[0061] After spinning, remove the aluminum foil and place it at room temperature for 12 hours to fully hydrolyze the nanofibers; put the placed aluminum foil in a crucible and put it into a mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com