Preparation and application of oxidation catalyst taking cerium-zirconium-silicon composite oxide as carrier

A technology of composite oxides and oxidation catalysts, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst carriers, etc., can solve high light-off temperature, low oxidation catalytic activity, and conversion Low-level problems, to achieve the effect of low ignition temperature, large specific surface area and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

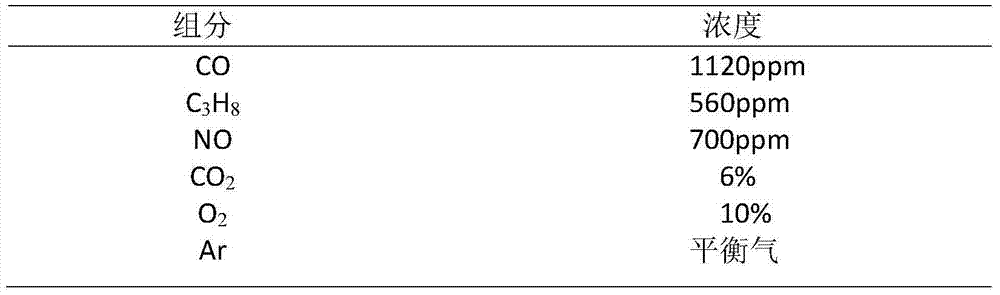

[0035] A method for preparing a diesel vehicle oxidation catalyst with cerium-zirconium-silicon composite oxide as a carrier, the specific preparation steps are as follows:

[0036] The cerium-zirconium-silicon composite oxide support material is prepared by hydrothermal synthesis: under the condition of stirring at room temperature, weigh 5g of cerous nitrate, 2.5g of zirconyl nitrate and 14g of silica sol with a content of 20% (wt) and mix evenly to form Mix the metal salt solution. Under the condition of vigorous stirring, add 2 mol / L ammonia solution dropwise into the metal salt solution until the pH value is 9.5 to stop the dropwise addition. ℃ hydrothermal reaction for 3h. Take it out and cool it down, vacuum filter the resulting precipitate, wash it with deionized water until it is neutral, dry it at 100°C in air atmosphere for 12h, put it in a muffle furnace and bake it at 500-1000°C in air atmosphere for 5h to get cerium Zirconium-silicon composite oxide, the result...

Embodiment 2

[0054] Concrete preparation method step is basically the same with activity evaluation experiment and implementation case 1, and difference is:

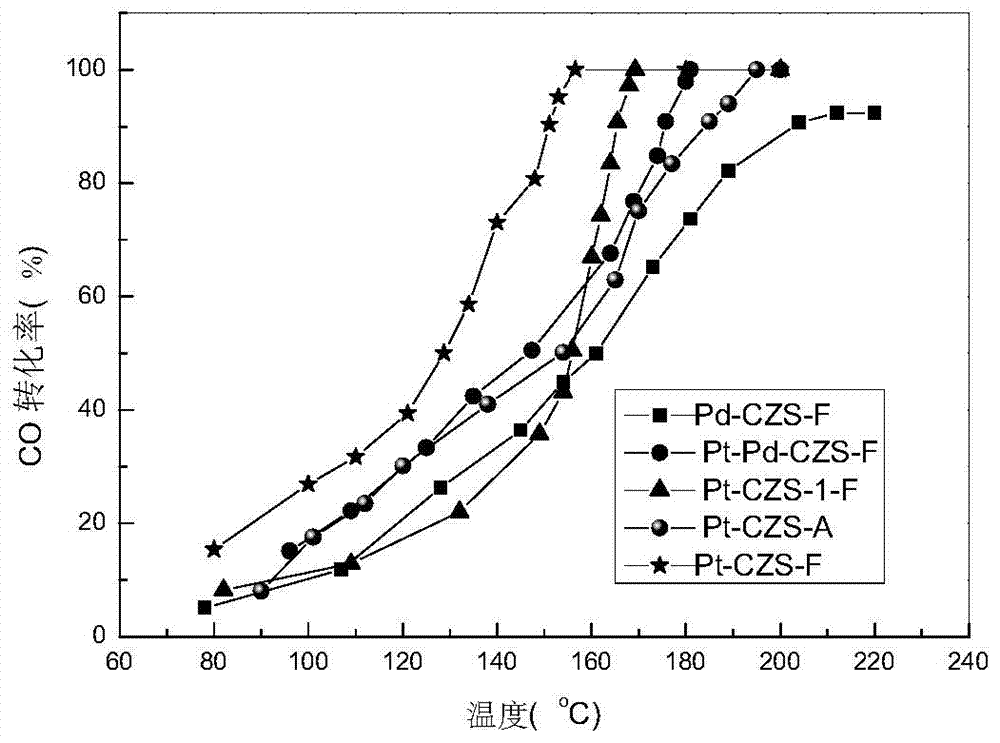

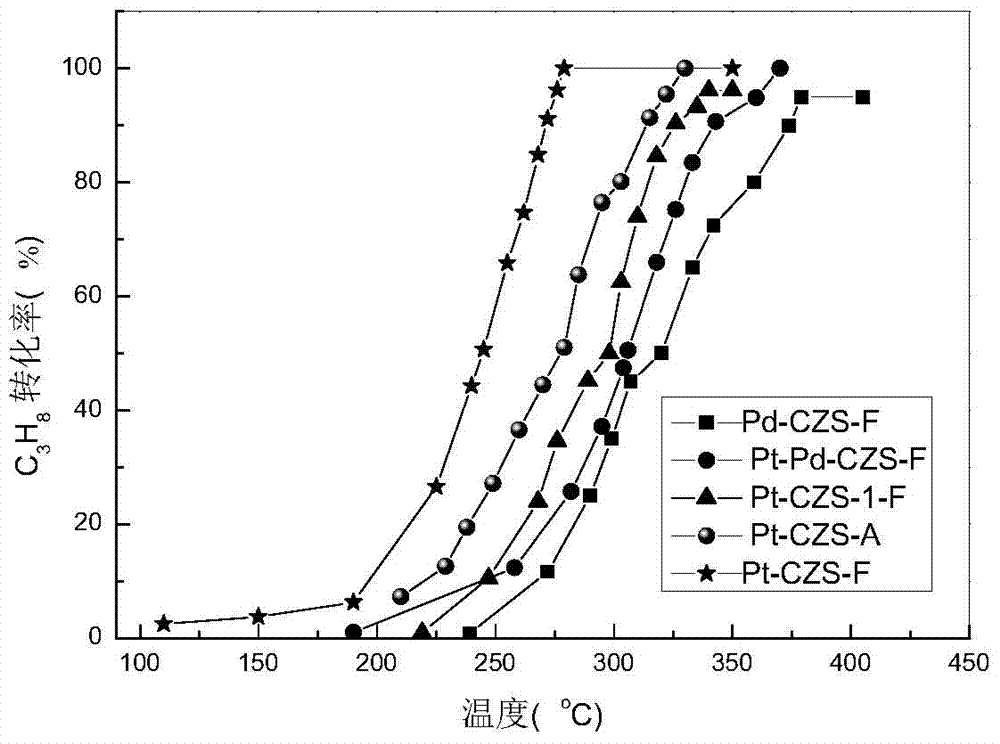

[0055] When preparing the cerium-zirconium-silicon composite oxide support material, under the condition of stirring at room temperature, weigh 13g of cerous nitrate, 7.5g of zirconyl nitrate and 35g of silica sol with a content of 20% (wt) and mix evenly to form a mixed metal salt solution . The cerium-zirconium-silicon composite oxide support material is obtained by calcination at 1000°C for 5 hours, and its specific surface area is 196.1m 2 / g, the pore volume is 0.39cm 3 / g, the average pore diameter is 6.4nm, and the catalyst obtained is denoted as Pt-CZS-A. Carry out the activity evaluation experiment such as embodiment 1 under the simulated atmosphere of diesel vehicle exhaust in the laboratory, the catalyst Pt-CZS-A prepared is to the CO catalytic oxidation activity in diesel vehicle exhaust see figure 1 , for C in diesel ...

Embodiment 3

[0057] The specific steps of the preparation method and the activity evaluation experiment are basically the same as those in Example 1, the difference is: when preparing the cerium-zirconium-silicon composite oxide carrier material, weigh 9g of cerous nitrate, 5g of zirconyl nitrate and stir at room temperature. Mix evenly with 24.5g content of 20% (wt) silica sol to form a mixed metal salt solution, the amount of noble metal added is 0.5% (wt) of the slurry, and the resulting catalyst is designated as Pt-CZS-1-F. Carry out the activity evaluation experiment as embodiment 1 under the simulated atmosphere of diesel vehicle exhaust in the laboratory, the catalyst Pt-CZS-1-F prepared is to the CO catalytic oxidation activity in diesel vehicle exhaust see figure 1 , for C in diesel vehicle exhaust 3 h 8 Catalytic oxidation activity see figure 2 , Table 2 lists the Pt-CZS-1-F catalyst for CO and C 3 h 8 Catalytic oxidation results, it was found from Table 2 that the Pt-CZS-1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com