Method for preparing copper, zinc, tin and sulfur film material

A technology of copper-zinc-tin-sulfur and thin-film materials, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, and photovoltaic power generation. It can solve the problems of difficult process control, high manufacturing cost, and poor operation convenience, and improve solar energy absorption. High efficiency and photoelectric conversion efficiency, easy operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

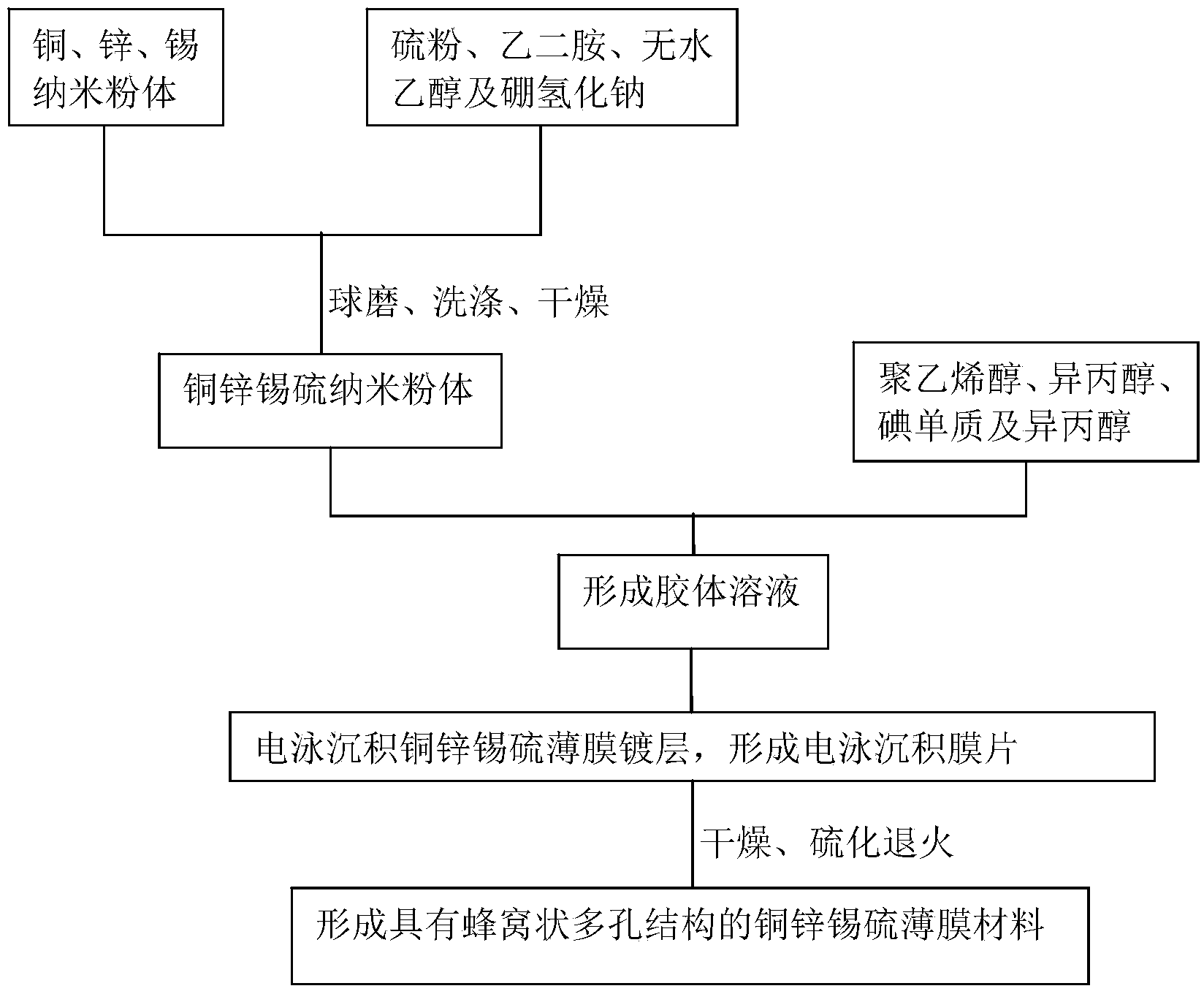

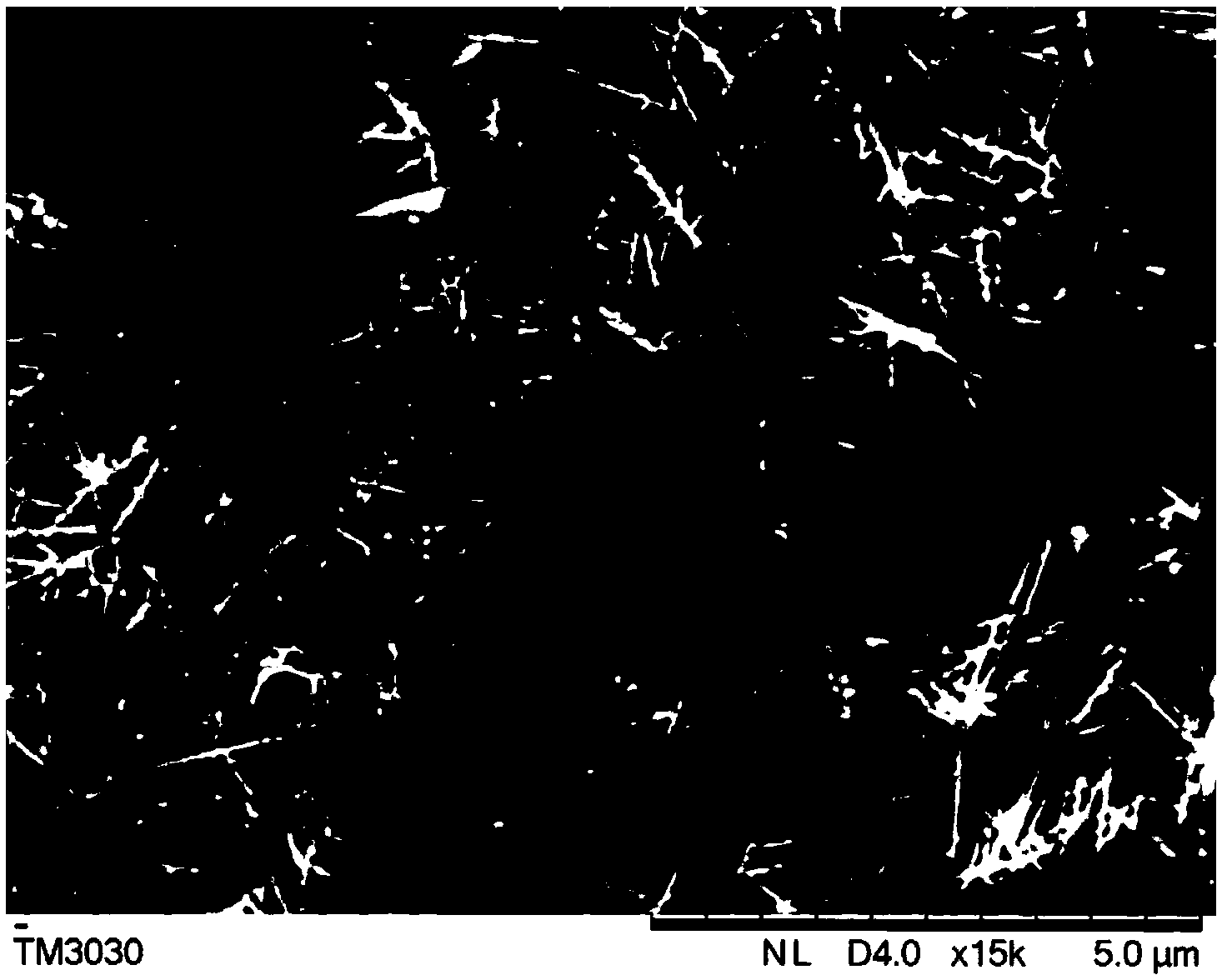

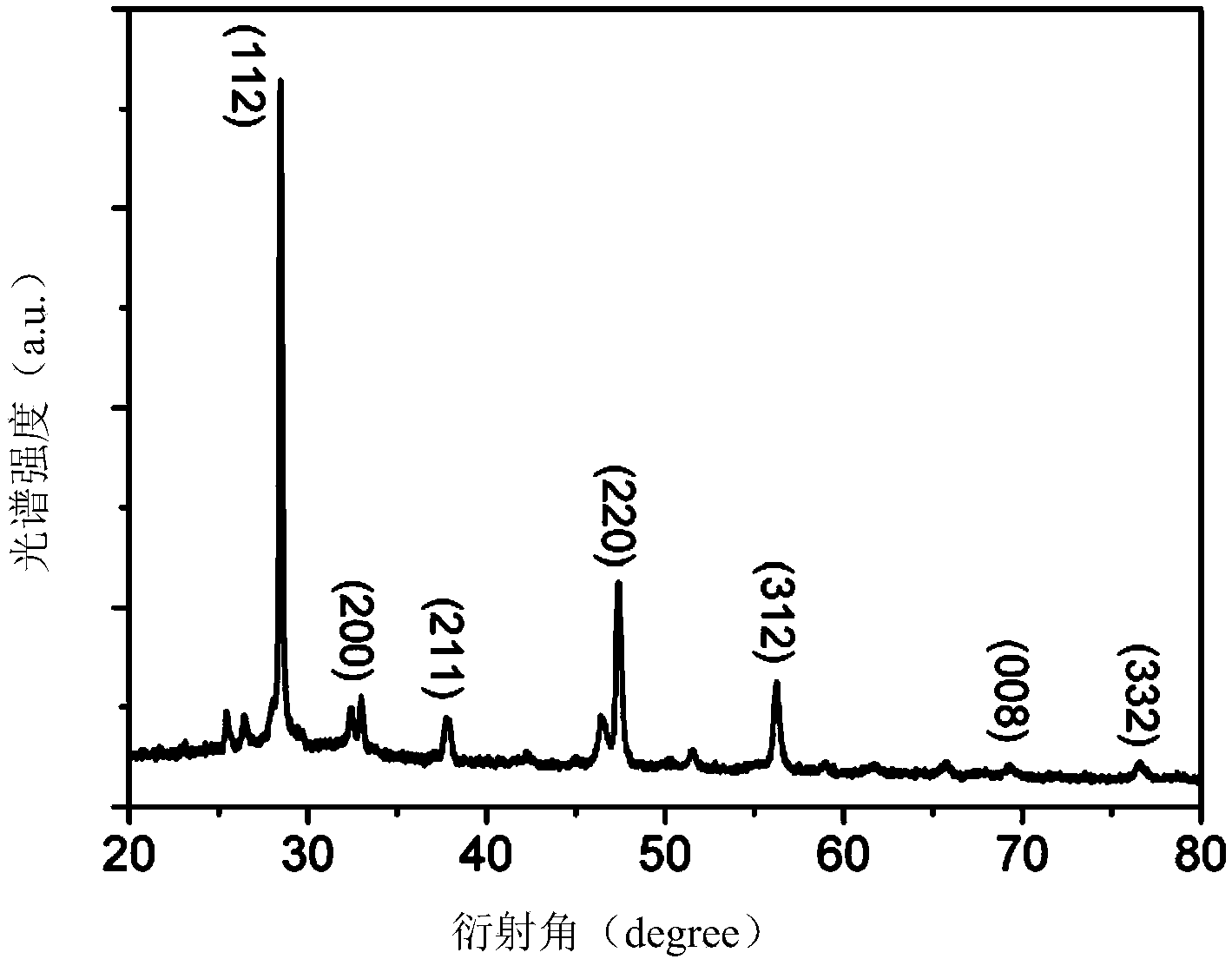

[0033] like figure 1 As shown in the figure, a method for preparing a copper-zinc-tin-sulfur film material of the present invention includes the following steps: firstly, using copper, zinc, and tin nano-powders as raw materials, mixing with appropriate proportions of sulfur powder, ethylenediamine, anhydrous ethanol and sodium borohydride are evenly mixed, washed and dried after high-energy vibration ball milling to obtain copper-zinc-tin-sulfur nano-powder; secondly, the copper-zinc-tin-sulfur nano-powder obtained in the previous step is mixed with polyvinyl alcohol, isopropanol, iodine The element and isopropanol are uniformly mixed to form a colloidal solution; then, the colloidal solution is used as an electrophoretic solution, and a copper-zinc-tin-sulfur thin film coating is electrophoretically deposited on the substrate by an electrophoretic deposition method to form an electrophoretic deposition film; finally, the electrophoretic deposition film is dried and sulfidati...

Embodiment

[0044] In this example, the method for preparing a copper-zinc-tin-sulfur thin film material with a honeycomb porous structure includes the following steps:

[0045] 1. Weigh 1.92g of copper, 0.97g of zinc, 1.7775g of tin nanopowder, 1.92g of sublimation sulfur powder and 0.13g of sodium borohydride, respectively, and use a graduated cylinder to measure 22ml of absolute ethanol and 2ml of ethylenediamine. The above mixture is uniformly mixed with magnetic stirring to form a slurry;

[0046]2. Put the slurry into a grinding jar with a volume of 70 ml, add 70 g of grinding balls, seal the ball milling jar under the protection of argon and place it in a high-speed vibration ball mill, and grind it at a vibration frequency of 500 times / min. 48 hours;

[0047] 3. The material obtained by ball milling in step 2 is successively washed 3 times with absolute ethanol and deionized water, and the centrifugal speed is set to 500 rpm for 3 minutes; the product after centrifugal washing is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com