A kind of preparation method of copper-zinc-tin-sulfur film material

A technology of copper-zinc-tin-sulfur and thin-film materials, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, and photovoltaic power generation. Solar absorptivity and photoelectric conversion efficiency, the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

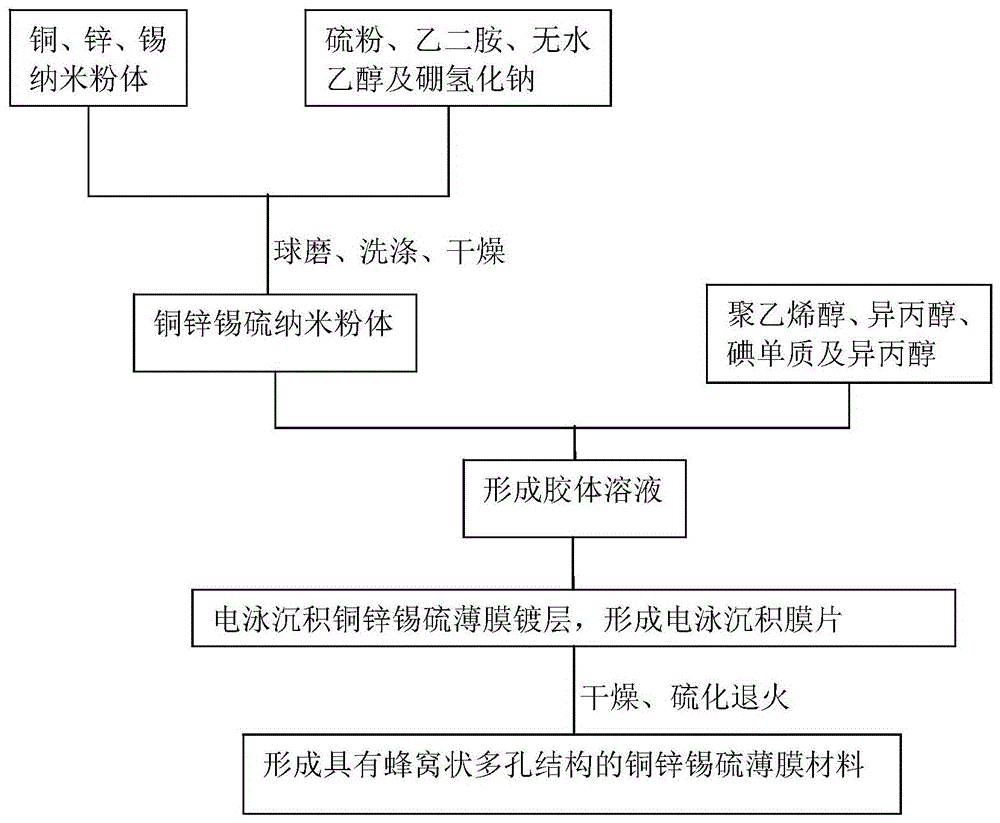

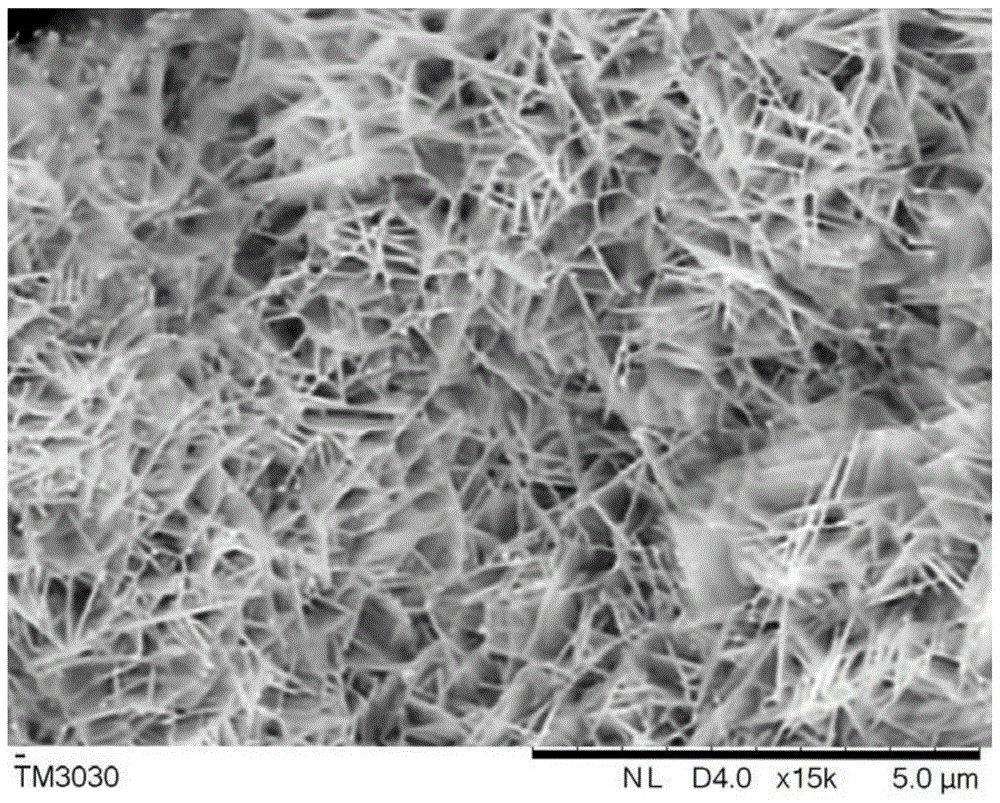

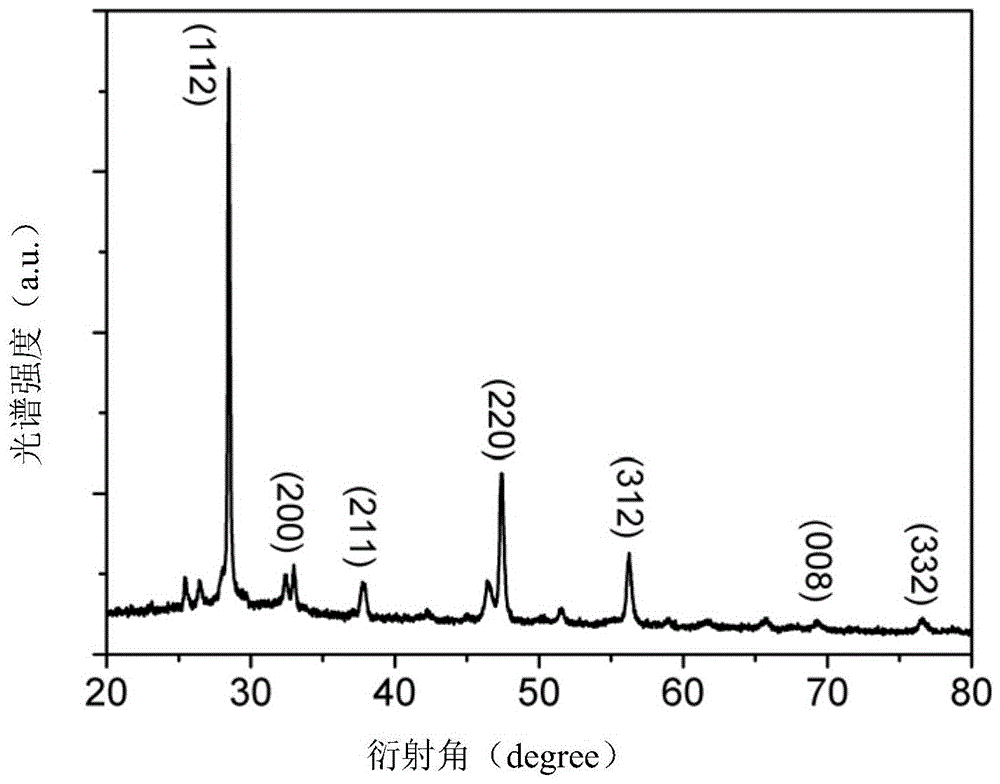

[0033] Such as figure 1 Shown, the preparation method of a kind of copper-zinc-tin-sulfur film material of the present invention comprises the following steps: first, take copper, zinc, tin nano-powder as raw material, with sulfur powder, ethylenediamine, dehydrated alcohol of appropriate ratio and sodium borohydride are evenly mixed, washed and dried after high-energy vibration ball milling to obtain copper-zinc-tin-sulfur nano-powder; secondly, the copper-zinc-tin-sulfur nano-powder obtained in the previous step is mixed with polyvinyl alcohol, isopropanol, iodine The elemental substance and ammonia water are uniformly mixed to form a colloidal solution; then, the colloidal solution is used as an electrophoretic solution, and the copper-zinc-tin-sulfur thin film coating is electrophoretically deposited on the substrate by the electrophoretic deposition method to form an electrophoretic deposition film; finally, the electrophoretic deposition film is dried and vulcanized Afte...

Embodiment

[0044] In this example, the method for preparing a copper-zinc-tin-sulfur film material with a honeycomb porous structure comprises the following steps:

[0045] 1. Weigh 1.92g of copper, 0.97g of zinc, 1.7775g of tin nanopowder, 1.92g of sublimed sulfur powder and 0.13g of sodium borohydride, and use a graduated cylinder to measure 22ml of absolute ethanol and 2ml of ethylenediamine. The above mixture is uniformly mixed with magnetic stirring to form a slurry;

[0046] 2. Put the slurry into a grinding tank with a volume of 70ml, add 70g of grinding balls, seal the grinding tank under the protection of argon and place it in a high-speed vibrating ball mill for ball milling at a vibration frequency of 500 times / min 48 hours;

[0047] 3. Centrifuge and wash the material obtained in step 2 with absolute ethanol and deionized water for 3 times, set the centrifugal speed at 500 rpm, and centrifuge for 3 minutes; put the centrifuged and washed product in a vacuum drying oven , drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com