Nano coarsening composite graphical sapphire substrate and manufacturing method

A sapphire substrate, composite patterning technology, applied in chemical instruments and methods, nanotechnology, crystal growth, etc., can solve the problems of low light extraction efficiency of GaN-based LEDs, increase light extraction efficiency and light output power, and change the propagation. Direction, effects that increase the chance of light escaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

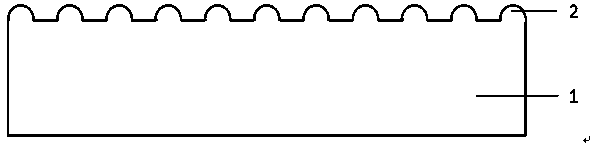

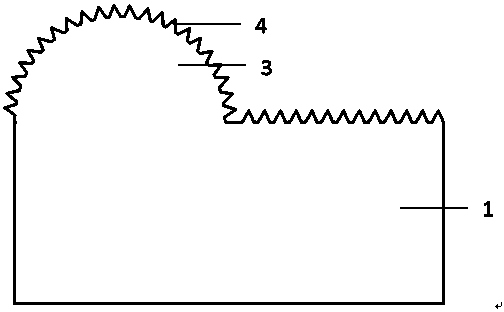

[0036] (1) A micron-scale pattern 2 is prepared on a sapphire substrate 1 .

[0037] Using existing conventional ICP or wet etching method (deposit a layer of silicon dioxide mask on the sapphire substrate; coat a layer of photoresist on the mask layer, use ICP equipment to etch the mask layer to form a mask film pattern; wet etching of sapphire with a mixed solution of sulfuric acid and phosphoric acid.). Micron-scale figures can be hemispheres, pyramids or truncated pyramids, the height of the figure is 1 μm, and the diameter of the bottom surface is 2 μm (the diameter of the bottom surface of the pyramid and prism, that is, its longest diagonal).

[0038] (2) The substrate is cleaned, and then a silicon dioxide film with a thickness of 200 nm is deposited on the micron-scale pattern 1 .

[0039] (3) Clean the substrate, then deposit a silver film with a thickness of 50nm on the silicon dioxide film, anneal in the air, at a temperature of 300 degrees, and for 1000 seconds, ...

Embodiment 2

[0045] (1) Same as step (1) of Example 1.

[0046] (2) The substrate is cleaned, and then a silicon dioxide film with a thickness of 1000 nm is deposited on the micron-scale pattern 1 .

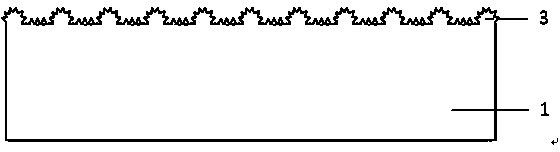

[0047] (3) on the silicon dioxide film of step (2), deposit the silver thin film of one deck thickness 500nm again; Anneal in oxygen, temperature 900 degree, time 30s, make silver thin film agglomerate and be nano particle, the formed silver nano particle The pattern is an irregular silver nanoparticle pattern with a height of 30nm and a bottom width of 200nm.

[0048] (4) transfer the nanoparticle pattern to the silicon dioxide film by a wet etching pattern transfer method, specifically the aqueous solution of hydrofluoric acid (the volume ratio of hydrofluoric acid and water is 1:5) to transfer the nanoparticle pattern to on the silicon dioxide film.

[0049] (5) Silver nanoparticles are removed by corrosion. The corrosion solution is a mixed solution of ammonia, hydrogen peroxide and wat...

Embodiment 3

[0053] (1) Same as step (1) of Example 1.

[0054] (2) depositing a silicon dioxide film with a thickness of 500nm on the micron-scale pattern formed in step (1);

[0055] (3) On the silicon dioxide film of step (2), deposit a silver film with a thickness of 300nm; anneal in the air, at a temperature of 700 degrees, for 200s, to make the silver film agglomerate and be nanoparticles, which are formed by silver nanoparticles The figure is an irregular silver nanoparticle figure with a height of 155nm and a bottom width of 20nm.

[0056] (4) is the same as the process of step (4) in embodiment (1).

[0057] (5) Silver nanoparticles are removed by corrosion. The corrosion solution is a mixed solution of ammonia, hydrogen peroxide and water. The volume ratio of ammonia and hydrogen peroxide is 3:1, and the volume ratio of the mixture of ammonia and hydrogen peroxide to water is 1:0.2.

[0058] (6) is the same as the process of step (6) in embodiment (1).

[0059] (7) Put the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com