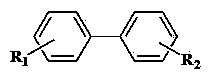

Photocatalysis synthesis method of biphenyl compounds

A synthesis method and compound technology, which is applied in the field of synthesis of biphenyl compounds, can solve the problems that catalysts cannot be recycled, and achieve the effects of short reaction cycle, simple operation and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]

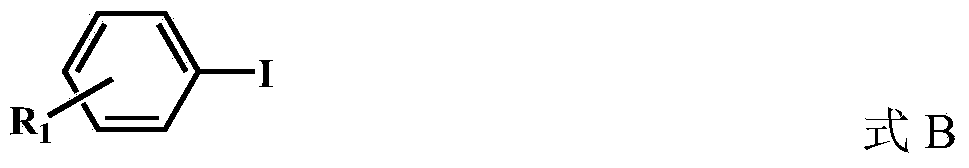

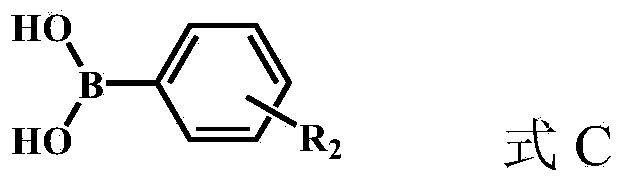

[0028] After mixing iodobenzene, phenylboronic acid, and potassium carbonate uniformly according to the molar ratio of 1:1:2, fully dissolve the above-mentioned reactant with ethanol containing 5% (volume fraction) of water, and add palladium / silicon carbide containing 0.5wt.% palladium Catalyst, the molar ratio of palladium and iodobenzene is 1.2:10000, after stirring evenly, the dispersed suspension is irradiated with visible light for 30 minutes under the protection of argon at 20°C to obtain biphenyl, wherein the conversion rate of iodobenzene is 80%, and the target product selectivity is 95%.

Embodiment 2

[0030]

[0031] After mixing p-methyliodobenzene, phenylboronic acid, and sodium carbonate in a molar ratio of 1:1.5:3, the above-mentioned reactants are fully dissolved with ethanol containing 10% (volume fraction) of water, and palladium / Silicon carbide catalyst, the molar ratio of palladium to p-methyliodobenzene is 4.7:10000, after stirring evenly, the dispersed suspension is irradiated with visible light for 80 minutes under the protection of nitrogen at 30°C to obtain 4-methylbis Benzene, wherein the conversion rate of p-methyl iodobenzene is 90%, and the target product selectivity is 98%.

Embodiment 3

[0033]

[0034] After mixing p-methoxyiodobenzene, phenylboronic acid and cesium carbonate uniformly according to the molar ratio of 1:1.2:2.6, fully dissolve the above reactants with methanol containing 30% (volume fraction) of water, and add palladium containing 3wt.% palladium / silicon carbide catalyst, make the molar ratio of palladium and p-methoxyiodobenzene 7:10000, after stirring evenly, disperse the suspended liquid at 50 ℃ and under the protection of helium, and react with visible light for 180min to obtain 4- Methoxybiphenyl, wherein the conversion rate of p-methoxyiodobenzene is 93%, and the target product selectivity is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com