Nitrogen-doped carbon-coated graphite negative electrode material and preparation method thereof

A graphite negative electrode and coating technology, which is applied in the field of nitrogen-doped carbon-coated graphite negative electrode materials and its preparation, can solve the problem of first-time efficiency less than 360 specific capacity, affecting tap density, compaction density, and graphite sheet exfoliation cycle performance and other issues, to achieve the effect of being suitable for large-scale production, improving compaction density, excellent rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of nitrogen-doped carbon coated graphite negative electrode material is described in detail as follows, including the following steps:

[0024] (1) Coating: Weigh graphite and ionic liquid, add them to a high-speed mixer, and disperse at a speed of 500-5000 r / min for 1-4 hours. After the treatment, graphite coated with ionic liquid is obtained; the ionic liquid is N-methylbutylpyrrolidine bistrifluoromethanesulfonimide salt, N-methylbutylpiperidine bistrifluoromethanesulfonimide salt, 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide Sulfonimide salt, 1-ethyl-3-methylimidazole tetrafluoroborate, trimethylpropylammonium bistrifluoromethanesulfonimide salt and 1-hexyl-3-methylimidazole bistrifluoromethane At least one of the sulfonimide salts, the purity of the ionic liquid is greater than or equal to 98%, and the molar ratio of nitrogen and carbon is 2:9 to 6:9.

[0025] Compared with the traditional solid-state carbon source precursors, io...

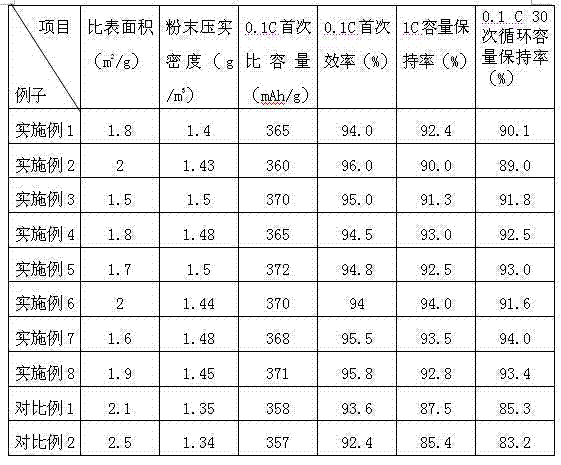

Embodiment 1

[0029] (1) Coating: Weigh 80 parts of graphite and 20 parts of ionic liquid, add them to a high-speed mixer, and disperse for 4 hours at a speed of 500r / min. After the treatment is completed, graphite coated with ionic liquid is obtained; the ionic liquid is N -Methylbutylpyrrolidine bistrifluoromethanesulfonimide salt, the purity of the ionic liquid is 98%, and the molar ratio of nitrogen and carbon is 2:9.

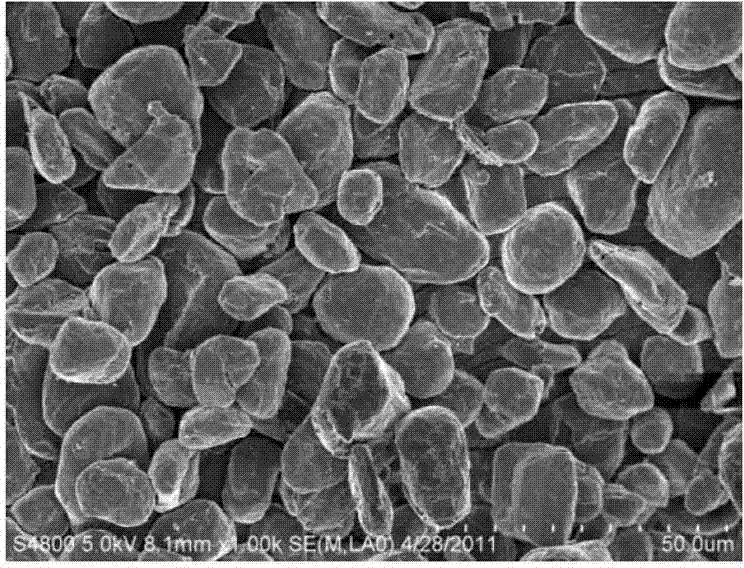

[0030] (2) Carbonization: The graphite coated with ionic liquid was placed in an atmosphere protection furnace for sintering, and the temperature was raised to 400 °C at a rate of 2 °C / min and kept for 8 hours to obtain a nitrogen-doped carbon-coated graphite negative electrode material. The nitrogen-doped carbon-coated graphite negative electrode material has a spherical shape, and the surface is uniformly covered with a layer of nitrogen-doped carbon material. The protective atmosphere used in the atmosphere protective furnace is selected from helium.

Embodiment 2

[0032] (1) Coating: 82 parts of graphite and 18 parts of ionic liquid were weighed, added to a high-speed mixer, and dispersed for 2 hours at a speed of 1000 r / min. After the treatment was completed, graphite coated with ionic liquid was obtained; the ionic liquid was N-methylbutylpiperidine bistrifluoromethanesulfonimide salt, the purity of the ionic liquid is 99%, and the molar ratio of nitrogen and carbon is 3:9.

[0033] (2) Carbonization: The graphite coated with ionic liquid was placed in an atmosphere protection furnace for sintering, and the temperature was raised to 800 °C at a rate of 8 °C / min and kept for 7 hours to obtain a nitrogen-doped carbon-coated graphite negative electrode material. The nitrogen-doped carbon-coated graphite negative electrode material has a spherical shape, and the surface is uniformly covered with a layer of nitrogen-doped carbon material. The protective atmosphere used in the atmosphere protective furnace is selected from nitrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com