Phosphine sulfur group electron transport material, preparation method and application thereof

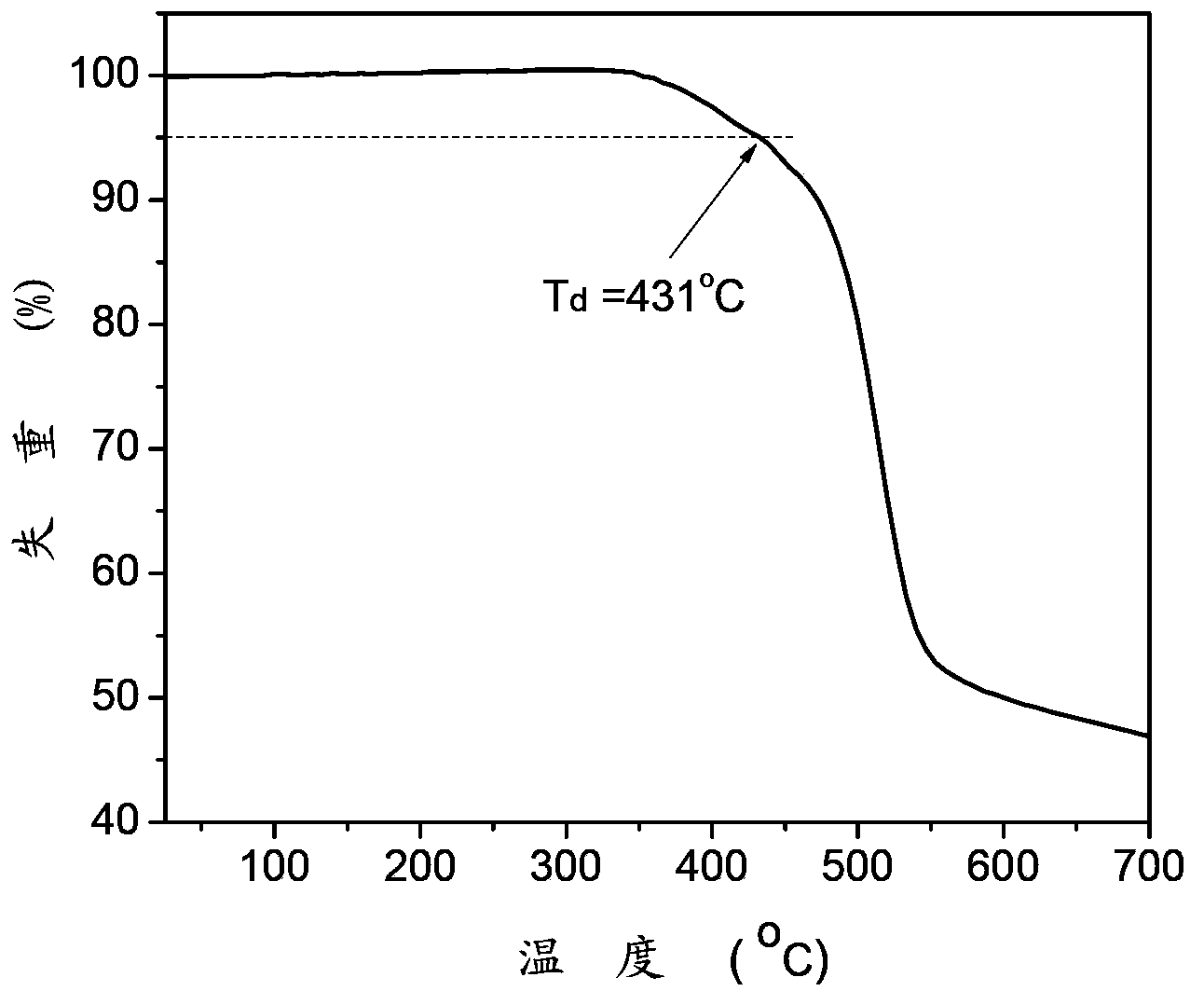

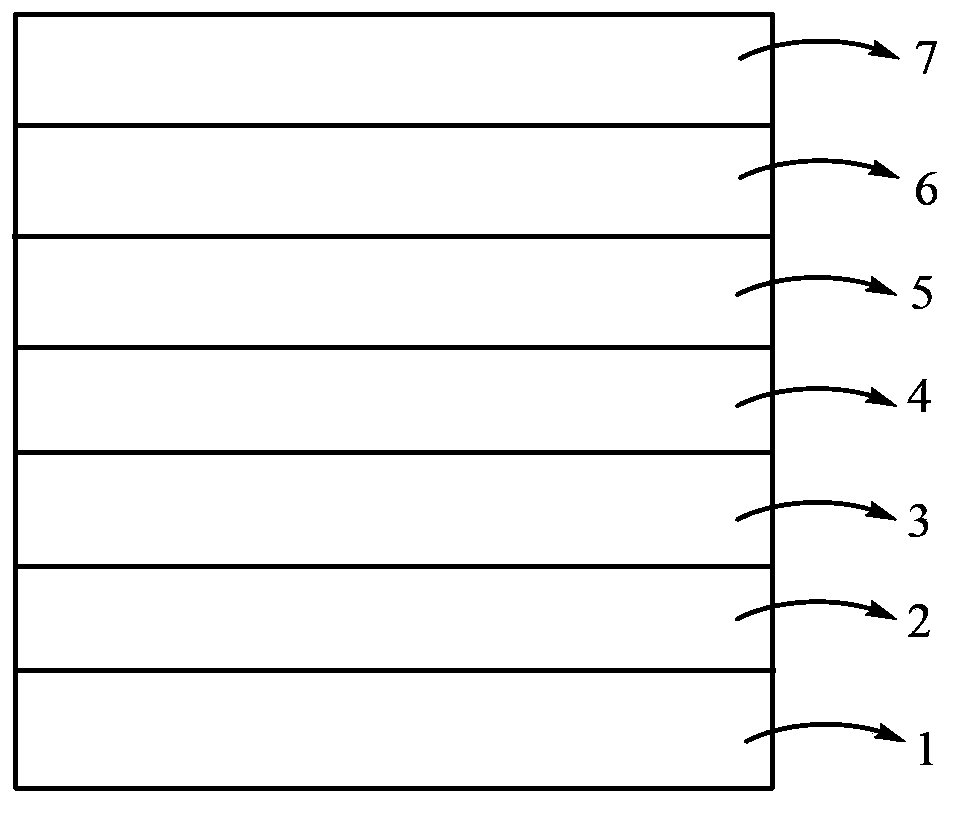

An electron transport material, phosphine-thio-based technology, applied in chemical instruments and methods, circuits, electrical components, etc., can solve problems such as poor thermal stability, poor luminous efficiency, and short service life of components, and achieve novel structure, High electroluminescence efficiency, high electron mobility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

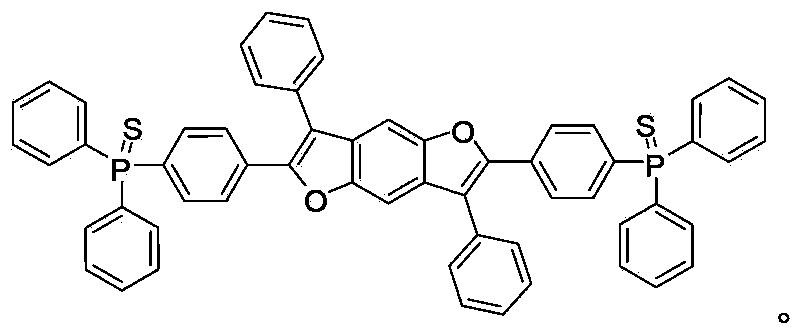

[0029] The preparation steps of the phosphinethio-based electron transport material of this example, namely 3,6-diphenyl-2,5-bis(4-(diphenylphosphinethio)phenyl)benzodifuran are as follows:

[0030]

[0031] Under the protection of argon, 3,6-diphenyl-2,5-dibromobenzodifuran (94 mg, 0.2 mmol), diphenyl (4-pinacol borate phenyl) phosphine sulfur ( 168mg, 0.4mmol) was added to a flask containing 10ml of toluene solvent, and after fully dissolving, potassium carbonate (2mL, 2mol / L) solution was added to the flask, vacuumed to remove oxygen and filled with argon, and then added bistriphenyl Phosphine palladium dichloride (5.6mg, 0.008mmol); the flask was heated to 90°C for Suzuki coupling reaction for 36h. Subsequently, the polymerization reaction was stopped after cooling down, and 50 ml of methanol was added dropwise to the flask for sedimentation; after filtering through a Soxhlet extractor, the mixture was sequentially extracted with methanol and n-hexane for 24 hours. The...

Embodiment 2

[0034] The preparation steps of the phosphinethio-based electron transport material of this example, namely 3,6-diphenyl-2,5-bis(4-(diphenylphosphinethio)phenyl)benzodifuran are as follows:

[0035]

[0036] Under the protection of a mixed gas of nitrogen and argon, 3,6-diphenyl-2,5-dibromobenzodifuran (140 mg, 0.3 mmol), diphenyl (4-pinacol borate phenyl) Phosphine sulfur (252mg, 0.6mmol) and 15mL tetrahydrofuran were added into a 50mL two-necked bottle, and after fully dissolved, a mixture of nitrogen and argon was introduced to exhaust the air for about 20 minutes, and tetrakistriphenylphosphine palladium (4mg, 0.003mmol ) into it, fully dissolved and then added sodium bicarbonate (3mL, 2mol / L) solution. Then, the mixed gas of nitrogen and argon was exhausted for about 10 minutes, and the two-neck flask was added to 70°C for Suzuki coupling reaction for 96 hours. Subsequently, the polymerization reaction was stopped after cooling down, and 40 mL of methanol was added to...

Embodiment 3

[0038] The preparation steps of the phosphinethio-based electron transport material of this example, namely 3,6-diphenyl-2,5-bis(4-(diphenylphosphinethio)phenyl)benzodifuran are as follows:

[0039]

[0040] Under nitrogen protection, 3,6-diphenyl-2,5-dibromobenzodifuran (140mg, 0.3mmol), diphenyl(4-pinacol borate phenyl)phosphine sulfur (277mg, 0.66mmol), palladium acetate (3.5mg, 0.015mmol) and three (o-methoxyphenyl) phosphine (21mg, 0.06mmol) were added to the flask containing 12mL of N,N-dimethylformamide, fully After dissolving, add potassium carbonate (3mL, 2mol / L) solution, then blow nitrogen into the flask and exhaust the air for about 30min; heat the flask to 130°C for Suzuki coupling reaction for 12h. Subsequently, stop the polymerization reaction after cooling down, add 40mL methanol to the flask for precipitation, filter through a Soxhlet extractor and then extract with methanol and n-hexane for 24h; then use chloroform as a solvent to extract until colorless, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com