Polishing solution for processing ultra-smooth bearing steel surface and application thereof

A polishing fluid, bearing steel technology, applied in the material field to achieve the effect of low defect count, high removal rate, and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0045] Polishing liquid formula: 4wt% colloidal silicon dioxide, 0.75wt% glycine, and water as the balance, using nitric acid and potassium hydroxide to adjust the pH value to 2.0-10.0;

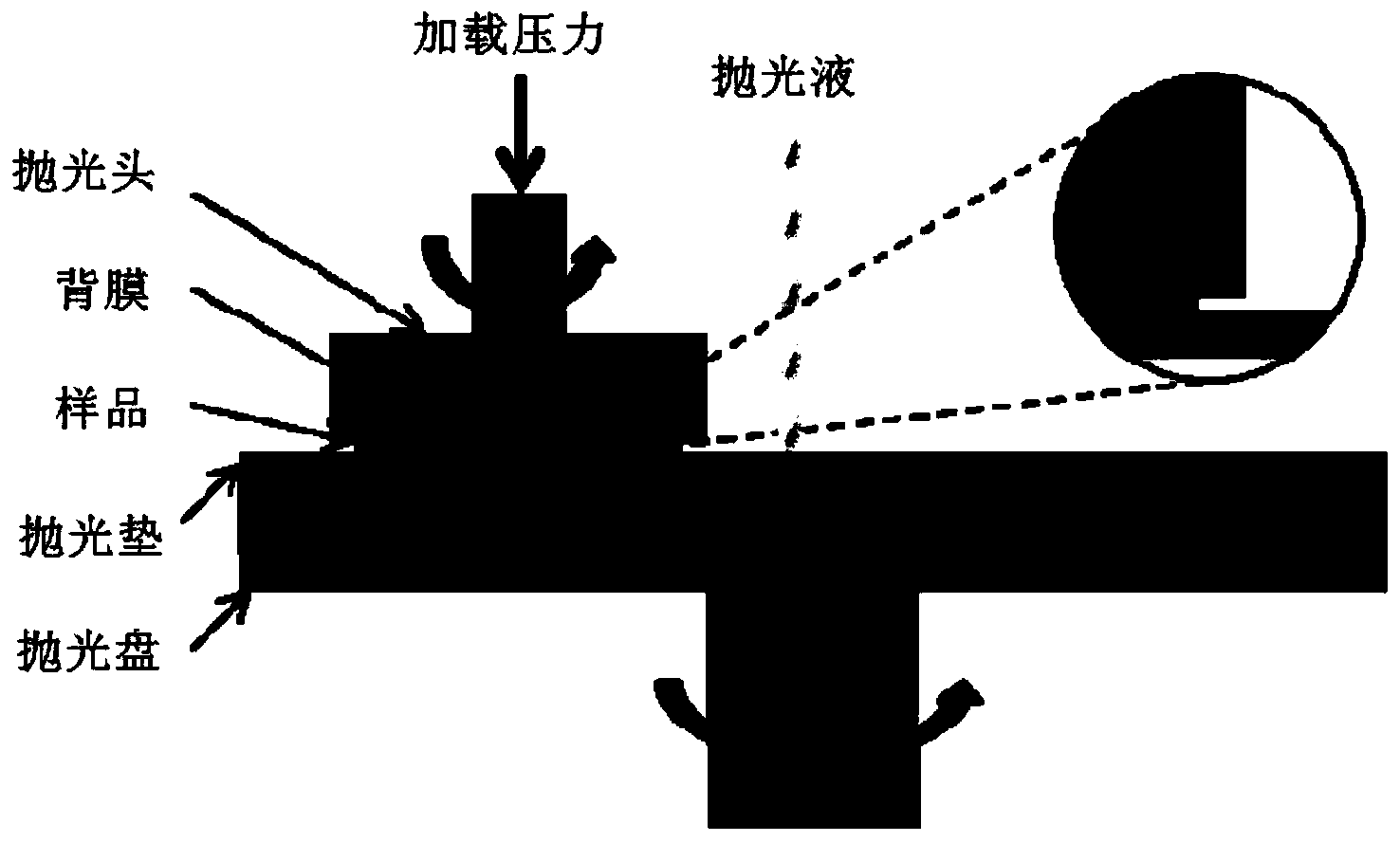

[0046] Polishing step: During chemical mechanical polishing, such as figure 1 As shown, the polishing liquid is continuously added to the polishing pad at a certain flow rate, and the sample on the polishing head is in contact with the polishing pad under the applied pressure, and the polishing pad and the sample rotate in the same direction to continuously replenish the polishing liquid to the contact area. The surface material is planarized and removed under the synergistic action of the chemical reaction of the polishing fluid and mechanical grinding, thereby achieving local and global planarization. It is worth noting that the above usage method is based on the traditional polishing machine. For a special polishing machine system, the execution method can be adjusted reasonably according ...

experiment example 2

[0053] Polishing liquid formula: 4wt% colloidal silicon dioxide, 1.05wt% serine or 0.75wt% glycine or 0.9wt% oxalic acid, the balance is water, and the pH value is adjusted to 4.0 with nitric acid and potassium hydroxide;

[0054] Polishing steps: the same as in Experimental Example 1, and the test results are shown in Table 3.

[0055] Table 3 test results

[0056]

[0057] It can be seen that after adding the metal complexing agent, the removal rate of bearing steel material is significantly increased, but the surface quality is deteriorated. By comparison, it was found that after adding aminoacetic acid, the material removal rate of bearing steel increased greatly, and the surface roughness increased the least. Therefore, aminoacetic acid is preferred as the metal complexing agent.

experiment example 3

[0059] Polishing liquid formula: 4wt% colloidal silicon dioxide, 0-1wt% hydrogen peroxide, 0.75wt% glycine, the balance is water, and adjust the pH value to 4.0 with nitric acid and potassium hydroxide;

[0060] Polishing steps: the same as in Experimental Example 1, and the test results are shown in Table 4.

[0061] Table 4 test results

[0062]

[0063] It can be seen that as the mass fraction of hydrogen peroxide increases, the static corrosion rate of bearing steel gradually decreases, the material removal rate first increases sharply and then decreases gradually, and the surface quality gradually improves, indicating that hydrogen peroxide has an important influence on the polishing performance of bearing steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com