A kind of highly active composite cellulase and its preparation and application method

A technology of compound cellulase and application method, which is applied in the application field of enzymatic hydrolysis and saccharification of lignocellulose, can solve the problem of low activity of BG type cellulase, achieve low-cost enzymatic hydrolysis, and improve the effect of enzymatic hydrolysis yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

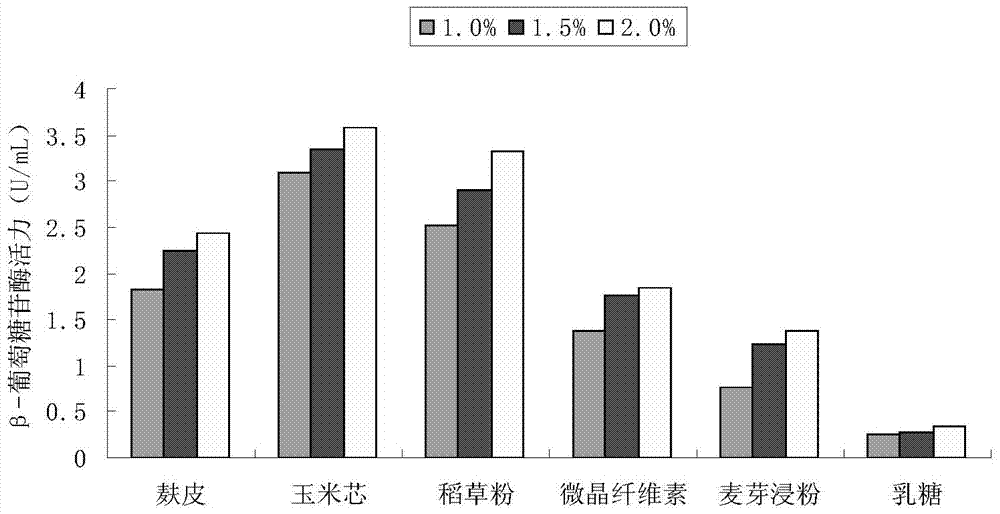

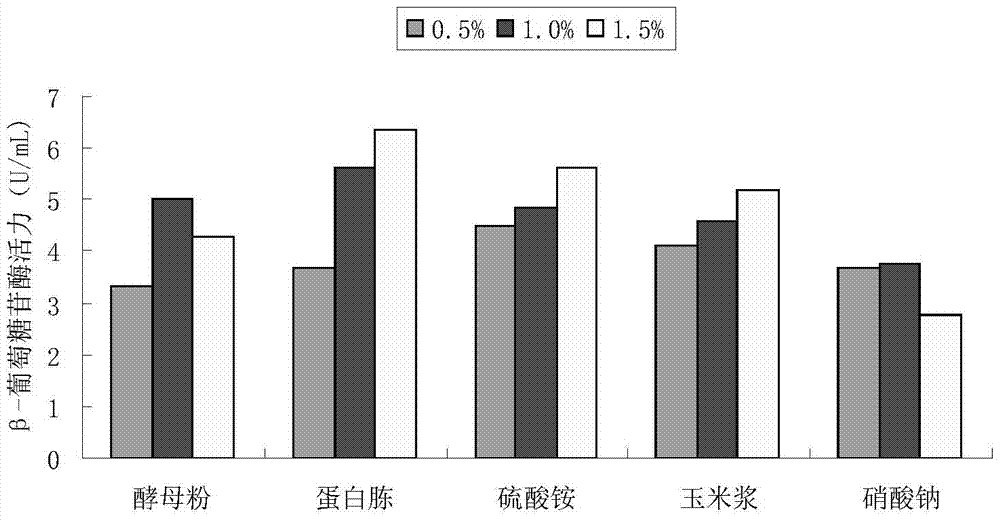

[0025] Embodiment 1: The present invention provides the optimization process of the production process of β-glucosidase by Aspergillus niger C112 by single factor and orthogonal test, specifically as follows.

[0026]Seed culture of Aspergillus niger C112: Pick two rings of spores from the Aspergillus niger C112 potato solid plate medium preserved in the laboratory, inoculate in a 250ml shaker flask containing 50ml potato medium, and cultivate at 28°C and 200r / min 2 to 2.5 days as the inoculum. Aspergillus niger C112 seed medium: potato 300g / L, glucose 20g / L, pH 6.80.

[0027] Enzyme-producing culture of Aspergillus niger C112: Inoculate the activated Aspergillus niger liquid with 6% (v / v) inoculum in a 250ml shake flask with 50ml enzyme-producing medium, at 28°C, under the condition of 200r / min Cultured for 5 days. All shake flask experiments were performed in triplicate. Centrifuge at 4000r / min for 10min, take the supernatant (crude enzyme solution) to measure its β-gluco...

Embodiment 2

[0052] Trichoderma reesei RUT C30 (Trichoderma reesei RUT C30) used in the present invention was purchased from the American Type Culture Collection (ATCC), number: ATCC 56765, and its cellulase production method, see reference 3.

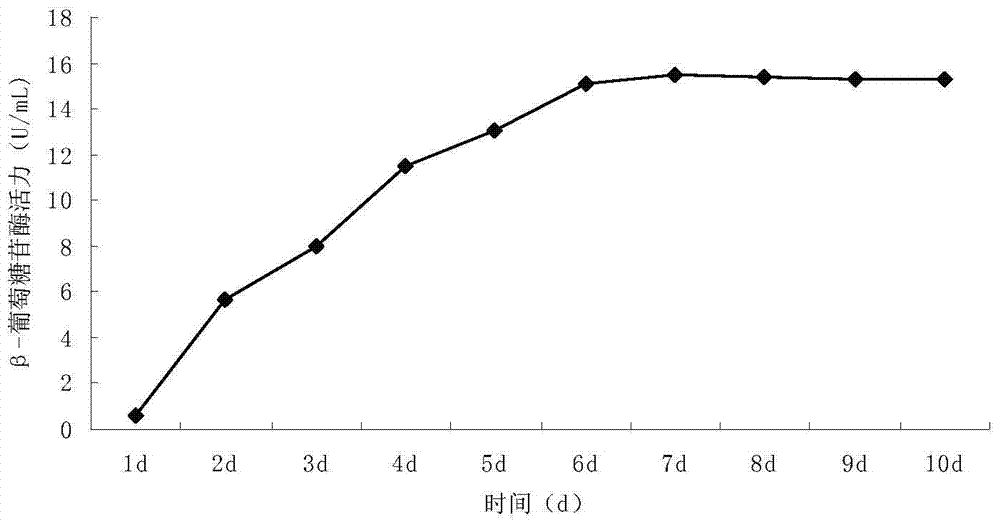

[0053] The preparation of the high-activity composite cellulase of the present invention is specifically as follows: the cellulase is produced by mutagenesis-selected Aspergillus niger C112 and Trichoderma reesei Ru-C30 (ATCC 56765) purchased from ATCC of the United States. The cellulase β-glucosidase activity produced by Aspergillus niger C112 is 15.496U / mL, and the enzyme activity of the filter paper is 0.215IU / mL. - Glucosidase activity is 20.491U / mL, filter paper enzyme activity is 0.93IU / mL. The cellulase β-glucosidase activity produced by Trichoderma reesei RUT C30 was 1.352U / mL, and the filter paper enzyme activity was 6.212IU / mL. After being concentrated by ultrafiltration concentrator UOF 48 (Tianjin Motianmo Technology Co., Ltd.), the β-...

Embodiment 3

[0055] The present invention adopts dilute phosphoric acid combined with steam explosion to pretreat poplar, specifically as follows: the pulverized poplar wood chips (1-2mm in diameter, 2-15mm in length) and dilute phosphoric acid (0.05%-2.0%) are mixed according to the solid-to-liquid ratio of 1:1 -1:10 pre-impregnation (1h-12h) followed by steam explosion (steam explosion machine QBS-80, developed by Hebi Zhengdao Heavy Machinery Factory), steam explosion conditions: steam explosion pressure is 0.5-2.5Mpa, pressure holding time is 90 -220s. The resulting steam explosion product is added with an appropriate amount of 0.05 mol / L, pH 4.8 citric acid buffer, and then adjusted to 4.5-6.0 with 1 mol / L ammonia water for detoxification, and then enzymatically hydrolyzed and saccharified.

[0056] The present invention utilizes composite cellulase to enzymatically hydrolyze and saccharify poplar wood, which is preferably specifically as follows: air-dried poplar wood chips, the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com