Warm-natured healthcare balsam pear particles and preparing method thereof

A technology of bitter gourd and granules, applied in food preparation, food forming, food science and other directions, can solve the problems of not being able to eat every day, gastrointestinal tract irritation, etc., and achieve the effects of increasing specific surface area, improving drug efficacy, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of preparation method of the bitter gourd granule of nature warm health care,

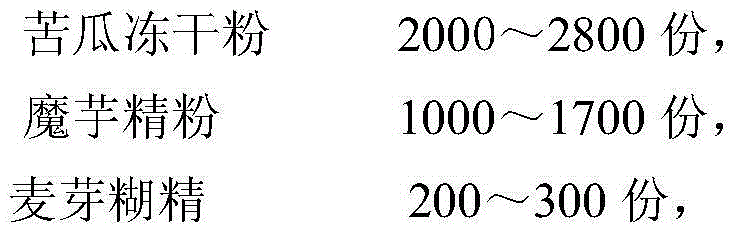

[0053] 1) The mass parts of raw materials are composed as follows:

[0054]

[0055] The preparation method is as follows:

[0056] 2) Preparation of balsam pear freeze-dried powder: squeeze balsam pear to obtain balsam pear juice, cool the balsam pear juice to 50°C at a cooling rate of 15°C / min for instant enzyme inactivation, then add 0.005% fruit juice to enzymatically hydrolyze for 2 hours, enzymatically hydrolyze After the solid-liquid separation of bitter gourd juice, ceramic membrane ultrafiltration is carried out. The pore size of the ceramic membrane is 200nm, and the membrane pressure is 0.13×10 5 pa, after ultrafiltration, carry out reverse osmosis concentration at normal temperature, then carry out vacuum concentration, freeze at -35°C after vacuum concentration, dry at 30°C, and obtain freeze-dried bitter gourd powder after cycle freeze-drying;

[0057] 3) Microwave ...

Embodiment 2

[0063] A kind of preparation method of the bitter gourd granule of nature warm health care,

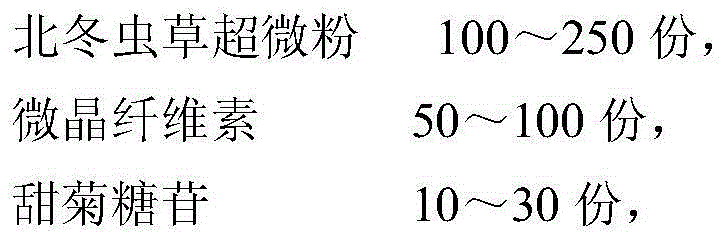

[0064] 1) The mass parts of raw materials are composed as follows:

[0065]

[0066] The preparation method is as follows:

[0067] 2) Preparation of balsam pear freeze-dried powder: squeeze balsam pear to obtain balsam pear juice, cool the balsam pear juice to 50°C at a cooling rate of 15°C / min for instant enzyme inactivation, then add 0.005% fruit juice to enzymatically hydrolyze for 2 hours, enzymatically hydrolyze After the solid-liquid separation of bitter gourd juice, ceramic membrane ultrafiltration is carried out. The pore size of the ceramic membrane is 200nm, and the membrane pressure is 0.13×10 5pa, after ultrafiltration, carry out reverse osmosis concentration at normal temperature, then carry out vacuum concentration, freeze at -35°C after vacuum concentration, dry at 30°C, and obtain freeze-dried bitter gourd powder after cycle freeze-drying;

[0068] 3) Microwave p...

Embodiment 3

[0073] A kind of preparation method of the bitter gourd granule of nature warm health care,

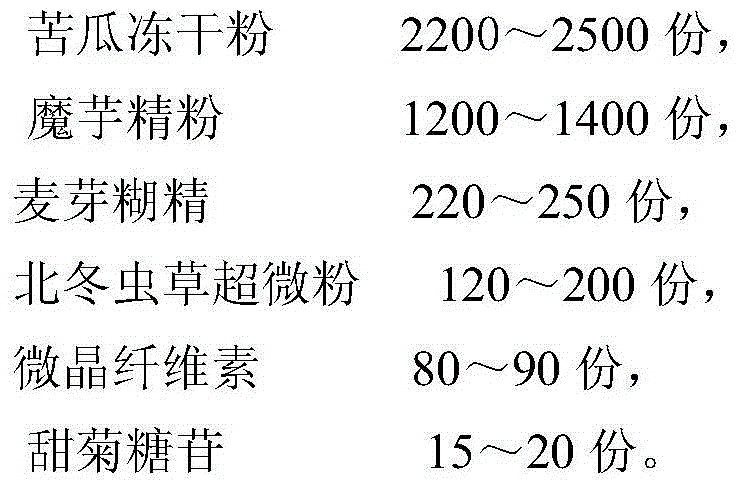

[0074] 1) The mass parts of raw materials are composed as follows:

[0075]

[0076] The preparation method is as follows:

[0077] 2) Preparation of balsam pear freeze-dried powder: squeeze balsam pear to obtain balsam pear juice, cool the balsam pear juice to 50°C at a cooling rate of 20°C / min for instant enzyme inactivation, then add 0.005% fruit juice to enzymatically hydrolyze for 2 hours, enzymatically hydrolyze After the solid-liquid separation of bitter gourd juice, ceramic membrane ultrafiltration is carried out. The pore size of the ceramic membrane is 200nm, and the membrane pressure is 0.13×10 5 pa, after ultrafiltration, carry out reverse osmosis concentration at normal temperature, then carry out vacuum concentration, freeze at -35°C after vacuum concentration, dry at 35°C, and obtain freeze-dried bitter gourd powder after cycle freeze-drying;

[0078] 3) Microwave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com