Catalyst for preparing propylene byproduct high-octane gasoline by taking methanol as raw material and preparation method of catalyst

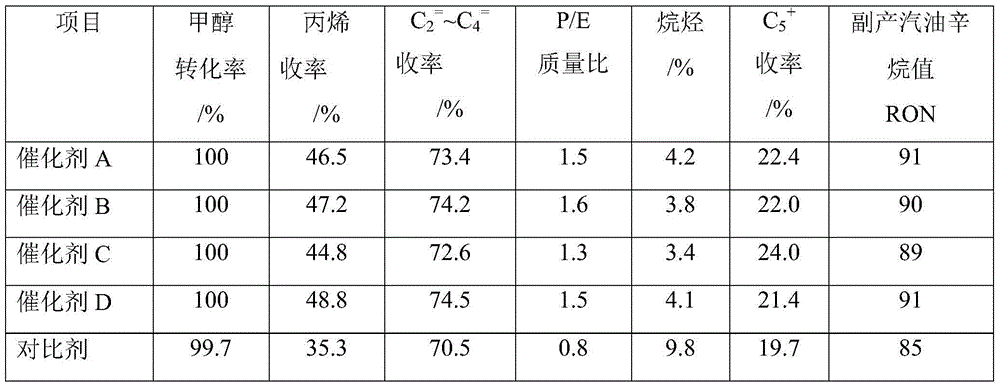

A technology for by-product high-octane and catalysts, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low octane number of by-product gasoline, low propylene selectivity, low catalyst activity, etc. problems, to achieve the effect of less by-products, high P/E weight ratio and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The crystallized ZSM-5 molecular sieve raw powder was roasted at 550°C for 2 hours to remove the template; mixed evenly with 10 times 0.2mol / L NaOH solution, heated to 70°C, and reacted at constant temperature for 1 hour; filtered and washed until NaOH 2 The mass fraction of O is less than 0.1%; add water to prepare molecular sieve slurry, add sulfuric acid solution, molecular sieve dry basis: H 2 O: H 2 SO 4 =1:10:0.2, heat up to 90°C, and react at constant temperature for 1 hour; filter and wash with water until the pH of the filtrate is greater than 6; add phosphoric acid and CeCl to the filter cake 3 The mixed aqueous solution was impregnated for 4 hours, dried, and calcined at 550°C for 3 hours to obtain modified molecular sieve A.

[0094] Modified molecular sieve A has a silicon-aluminum ratio of 300 and a specific surface area of 390m 2 / g, the total pore volume is 0.35mL / g, the mesopore volume accounts for 40% of the total pore volume, P 2 o 5 Mass perce...

Embodiment 2

[0097] The crystallized ZSM-5 molecular sieve raw powder was roasted at 550°C for 2 hours to remove the template agent; mixed evenly with 5 times the aqueous solution, added 0.1 times the dry basis of molecular sieve TEAOH, put it into a high-pressure reactor, and raised the temperature to 120°C. React at constant temperature for 12 hours; after cooling, filter and wash with water until Na 2 The mass fraction of O is less than 0.1%; add water to prepare molecular sieve slurry, add citric acid solution, molecular sieve dry basis: H 2 O: citric acid = 1:10:0.3, heat up to 90°C, and react at constant temperature for 1 hour; filter and wash with water until the pH of the filtrate is greater than 6; add ammonium phosphate and LaCl to the filter cake 3 The mixed aqueous solution was impregnated for 4 hours, dried, and calcined at 550°C for 3 hours to obtain modified molecular sieve B.

[0098] Modified molecular sieve B with a silicon-aluminum ratio of 200 and a specific surface ar...

Embodiment 3

[0101] Mix 70g (dry basis) modified molecular sieve A with 30g (dry basis) pseudo-boehmite evenly, add 1:1 nitric acid (nitric acid: carrier dry basis = 1mL: 100g) and water (water: carrier dry basis = 1 : 4) The prepared solution is kneaded into a dough, extruded in an extruder, dried at 120° C. for 12 hours, and calcined at 550° C. for 3 hours.

[0102] The above carrier was taken, impregnated with 30 g of gallium sulfate aqueous solution containing 3 g of gallium oxide at 65° C. for 2 hours, dried at 120° C. for 12 hours, and calcined at 550° C. for 4 hours to obtain catalyst A.

[0103] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com