Waste-drilling-fluid decoloring agent, and preparation method and application thereof

A technology of drilling waste liquid and decolorizing agent, which is applied in mining wastewater treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of poor treatment effect, low decolorization rate, secondary pollution, etc., and achieve reduction in treatment capacity and decolorization rate The effect of high and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

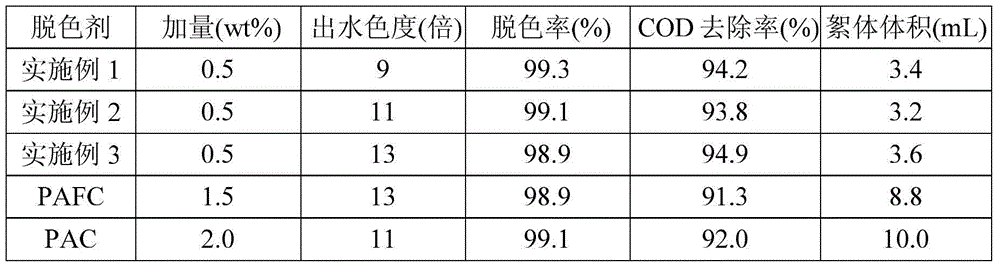

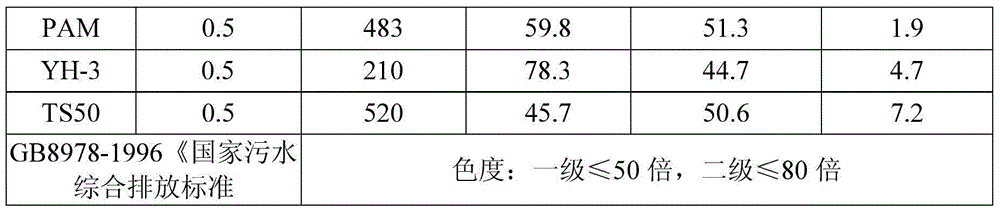

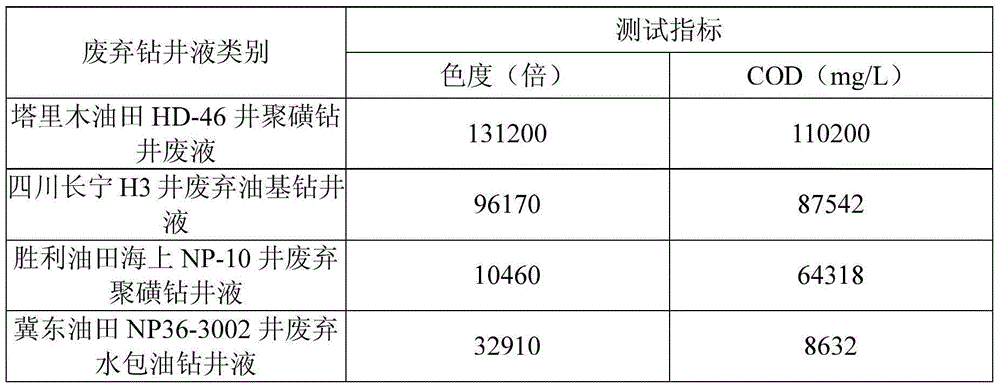

Examples

Embodiment 1

[0026] The present embodiment provides a decolorizing agent for drilling waste fluid, which is prepared by the following steps:

[0027] Step 1: Add 50mL of tap water to the flask, add 0.2g of aminotriacetic acid, stir and dissolve fully;

[0028] Step 2: Under continuous stirring, dissolve 12.5g of N-isopropylacrylamide, 37.5g of dimethyldiallyl ammonium chloride, 0.08g of ferrous sulfate and 0.32g of azobisisobutyl in turn Dimethyl acid;

[0029] Step 3: After passing nitrogen gas at a rate of 1.0L / min for 10min, seal the flask; adjust the constant temperature water bath oscillator to 35°C; put the flask into the constant temperature water bath oscillator, start the vibration, after 1h, stop the vibration, and continue the reaction for 3 hours After that, a jelly is obtained;

[0030] Step 4: Put the gelatinous material obtained by the polymerization reaction into a clean beaker, add acetone and ethanol for extraction and washing, put it in a drying oven, and dry it at 105...

Embodiment 2

[0032] The present embodiment provides a decolorizing agent for drilling waste fluid, which is prepared by the following steps:

[0033] Step 1: Add 60 mL of tap water to the flask, add 0.3 g of EDTA, stir and dissolve fully;

[0034] Step 2: under continuous stirring, successively dissolve 10g of acrylamide, 37.5g of methacryloyloxyethyltrimethylammonium chloride, 0.06g of sodium sulfite and 0.24g of ammonium persulfate;

[0035] Step 3: After passing nitrogen gas at 1.3L / min for 10min, seal the flask; adjust the constant temperature water bath shaker to 45°C, put the flask into the constant temperature water bath shaker, start the shaking, stop shaking after 1.5 hours, continue the reaction for 3 hours, to obtain a jelly;

[0036] Step 4: Put the gelatinous substance obtained by the polymerization reaction into a clean beaker, add acetone and ethanol for extraction and washing, put it in a drying oven, and dry it at 105°C for 5 hours to obtain a decolorizing agent for drill...

Embodiment 3

[0038] The present embodiment provides a decolorizing agent for drilling waste fluid, which is prepared by the following steps:

[0039] Step 1: add 70mL of tap water to the flask, add 0.4g of diethylenetriaminepentaacetic acid, stir and dissolve fully;

[0040] Step 2: under continuous stirring, successively dissolve 7.5g of methacrylamide, 22.5g of acryloyloxyethyltrimethylammonium chloride, 0.04g of sodium bisulfite and 0.16g of azobisisobutyronitrile;

[0041] Step 3: After passing nitrogen gas at 1.5L / min for 10min, seal the flask; adjust the constant temperature water bath shaker to 55°C, put the flask into the constant temperature water bath shaker, start the shaking, stop shaking after 2 hours, continue the reaction for 4 hours, to obtain a jelly;

[0042] Step 4: Put the colloidal liquid obtained by the polymerization reaction into a clean beaker, add acetone and ethanol for extraction and washing, put it in a drying oven, and dry it at 105°C for 5 hours to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com