Waterproof silicone rubber compound and preparation method thereof

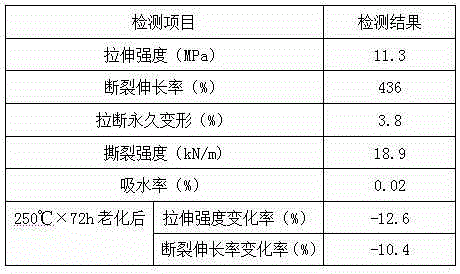

A technology of mixing rubber and silicone rubber, which is applied in the field of silicone rubber, can solve the problems of short service life and poor water resistance, achieve good heat resistance, high mechanical properties, and broaden the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A water-resistant silicone rubber compound made of the following raw materials by weight (kg): methyl vinyl phenyl silicone rubber 70, polysulfone ether 40, 1,1-di-tert-butylperoxycyclohexane 2.5, Orthoethyl silicate 6, zinc methacrylate 3.5, bismaleimide 2.5, spindle oil 8, subspherical silicon micropowder 16, dipropyl silicon glycol 4, magnesite powder 12, isopropyl tri(di Octyl pyrophosphate acyloxy) titanate 1.5, Fischer-Tropsch wax 4.5, 2-aminopropane 1.5, N,N'-diphenylethylenediamine 2.5, additive 3;

[0011] The preparation method of described auxiliary agent is as follows: a, get the raw material of following weight (kg): rosin pentaerythritol ester 4, 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate 3, zirconium fluoride 8. Thiophosphoric acid triphenyl isocyanate 3, 4,4′-biphenyl diphenol 1.5, triisopropanolamine boronate 4, methyl 2,2-dithienyl glycolate 2.5, bone glue powder 6 , tungsten carbide 8, decyl tetradecyl cetyl stearate 3.5, 2-(4-morpholino d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com