Production method of polyurethane latex condom and special mold thereof

A technology of polyurethane latex and production methods, which is applied in the direction of male contraceptives, etc., can solve the problems of difficulty in adapting to the industrial production of polyurethane condoms, the complex mold processing technology of PTFE condoms, and the inability to meet the requirements of industrial production pass rate, etc., and achieve easy batch production Variety of production and molding methods, and the effect of reducing the weight of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

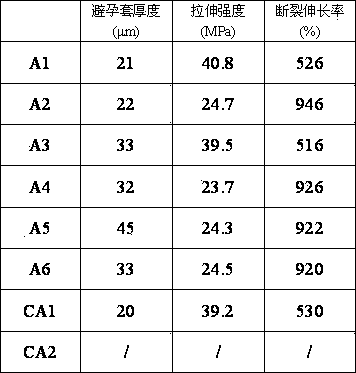

Embodiment 1

[0038] A production method of polyurethane latex condoms, using a 60m condom production line, transporting 2,000 molds at the same time on the production line, and sequentially dipping latex (on a dipping machine, glue temperature 28~35°C)→drying (60~70°C)→rolling Side→drying (80~90℃)→water flushing demoulding→centrifugal dehydration→finishing→finished product drying→electrical inspection step, polyurethane latex is polyester water-based polyurethane with a solid content of 55%, adding thickener sodium polyacrylate 0.1 wt %, leveling agent ethylene glycol monobutyl ether 1.5 wt%, defoamer n-butanol 0.5 wt%, stir evenly, filter and stop for defoaming, use polyethylene male condom mold, condom A1, condom can be obtained The body length is 180mm±2mm, and the sleeve body width is 50mm±1mm.

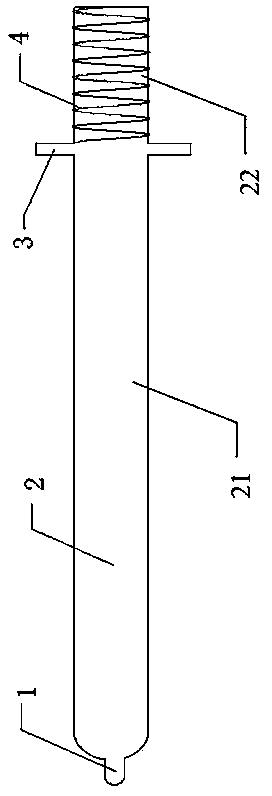

[0039] The polyurethane latex condom production special-purpose mold that the present embodiment provides, as figure 1 As shown, it includes a protruding head 1, a column body 2 and a circula...

Embodiment 2

[0044] A kind of polyurethane latex condom production method, adopts 120m condom production line, transports 4500 molds simultaneously on the production line, adopts the polyether type aqueous polyurethane of solid content 45%, adds thickening agent sodium polyacrylate 0.2 wt%, leveling agent B Diol monobutyl ether 1.0 wt%, defoamer n-butanol 0.5 wt%, stir evenly, filter and park for defoaming, use polyethylene male condom mold, soak latex (glue temperature 28~35°C) → dry ( 60~70°C)→crimping→drying (80~90°C)→water flushing and demoulding→centrifugal dehydration→finishing→finished product drying→electrical inspection, condom A2 can be obtained, the length of the condom body is 180mm±2mm, and the width of the body 50mm±1mm.

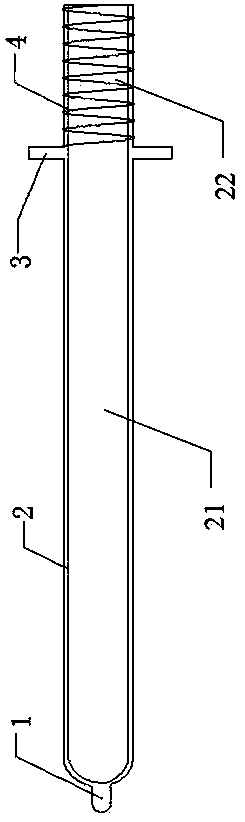

[0045] The polyurethane latex condom production special-purpose mold that the present embodiment provides, as figure 2 As shown, it includes a protruding head 1, a hollow cylinder 2 and a circular clamping pad 3, and the wall thickness of the hollow cylin...

Embodiment 3

[0049] A kind of polyurethane latex condom production method, solid content 40% polyester water-based polyurethane, add thickener carboxymethyl cellulose 0.3 wt%, leveling agent ethylene glycol monomethyl ether 2.5 wt%, defoamer secondary Octanol 1.0 wt%, using a polypropylene male condom mold, dipping in latex (glue temperature 28~35°C)→drying (60~70°C)→cooling (30~40°C)→second dipping in latex (glue temperature 28°C) ~35°C)→drying (60~70°C)→crimping→drying (90~100°C)→water flushing and demoulding→centrifugal dehydration→finishing→finished product drying→electrical inspection, condom A3 and length of condom body can be obtained 180mm±2mm, the sleeve width is 52mm±1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com