A kind of cyanide-free electroforming gold solution and electroforming gold method

A gold solution, electroforming technology, applied in electroforming, electrolysis process and other directions, to achieve the effect of low porosity, simple formula and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the present invention provides a kind of cyanide-free electroforming gold solution and electroforming gold method, the mass concentration of each component in the solution formula is: potassium chloroaurate (gold ion concentration meter) 15g / L, ammonium chloride 80g / L, potassium chloride 40g / L, dipotassium hydrogen phosphate 30g / L, additive 0.6ppm (including cerium chloride 0.1ppm, saccharin 0.5ppm).

[0026] The method of electroforming gold is as follows: Step 1. Polish the cathode substrate successively with coarse sandpaper and fine sandpaper, soak the polished substrate in degreasing solution, and degrease for 40 minutes; heat the water bath to 30°C, and degrease The liquid formula is: sodium hydroxide 5g / L, sodium carbonate 40g / L, dipotassium hydrogen phosphate 40g / L.

[0027] Step (2) Soak in the activation solution for 10 seconds, the activation solution is 10% dilute sulfuric acid, take it out, rinse it with distilled water, and put the cathode s...

Embodiment 2

[0030] Embodiment 2: the present invention provides a kind of cyanide-free electroforming gold solution and electroforming gold method, the mass concentration of each component in the solution prescription is: chloroauric acid (gold ion concentration meter) 10g / L, complexing agent (hydrogen chloride 20g / L+potassium chloride 80g / L), potassium dihydrogen phosphate 20g / L, additive 0.1ppm (cerium nitrate 0.05ppm, 2,2‐bipyridine 0.05ppm).

[0031] The method of electroforming gold is as follows: Step 1. Polish the cathode substrate successively with coarse sandpaper and fine sandpaper, soak the polished substrate in degreasing liquid, and degrease for 30 minutes; heat the water bath to 40°C, and degrease The liquid formula is: sodium hydroxide 10g / L, sodium carbonate 20g / L, dipotassium hydrogen phosphate 50g / L.

[0032] Step (2) Soak in the activation solution for 20s. The activation solution is 2% dilute hydrochloric acid. After taking it out, rinse it with distilled water and put...

Embodiment 3

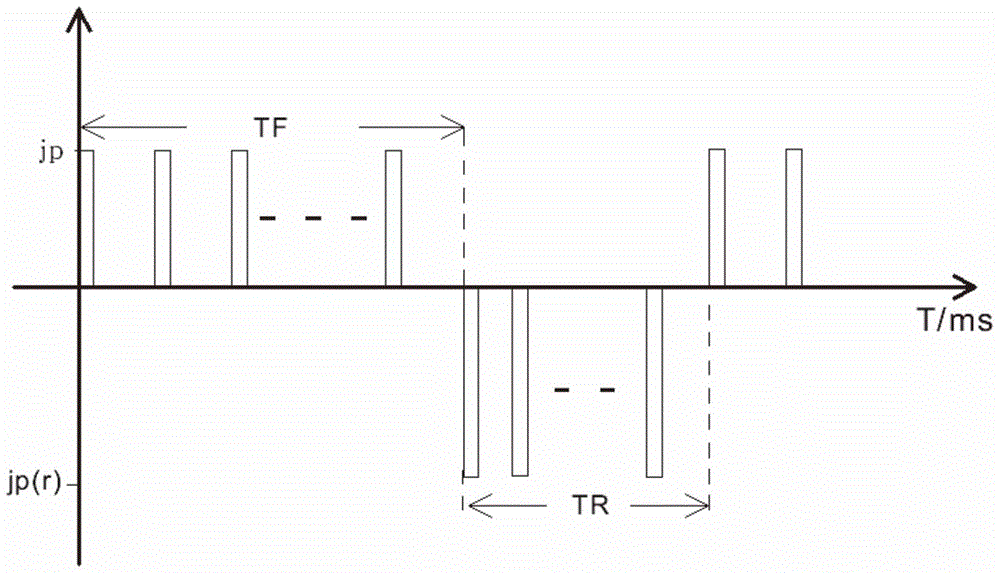

[0035] Embodiment 3: the present invention provides a kind of cyanide-free electroforming gold solution and electroforming gold method, the mass concentration of each component in the solution formula is: sodium chloroaurate (gold ion concentration meter) 40g / L, sodium chloride 160g / L, Sodium Sulfate 20g / L, Dipotassium Hydrogen Phosphate 20g / L, Sodium Dihydrogen Phosphate 30g / L, Additive 10.5ppm (5ppm Potassium Antimony Tartrate, 5ppm Sodium Lauryl Sulfate, 0.5ppm Saccharin), Solution pH 6, the working temperature is 60°C. Periodic commutation pulsation pulse parameters are: forward pulse frequency 500Hz, conduction time 80ms, duty cycle 70%, reverse pulse frequency 500Hz, conduction time 30ms, duty cycle 30%, average current density 2.0A / dm 2 . All the other unrelated methods are the same as in Example 1. After electroforming for 9.5 hours, a golden yellow, dense and flat gold layer was obtained, with a thickness of 240um, a mass fraction of 99.9%, and a hardness of 93Hv. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com