Carbon-coated cobalt sulfide material as well as preparing method thereof and application of carbon-coated cobalt sulfide material in aspect of water cracking hydrogen production

A cobalt sulfide and carbon coating technology, applied in chemical instruments and methods, electrolysis components, electrolysis processes, etc., can solve the problems of hydrogen production from water that have not yet been applied electrocatalytic splitting, the reaction system is not environmentally friendly, and the synthesis method is cumbersome. The effect of catalytic stability, cheap synthetic raw materials, and simple synthetic method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 123mg cobalt nitrate hexahydrate and 300mg thiocyanuric acid evenly, put the resulting mixture into a quartz tube, and raise it from room temperature to 700°C at a rate of 15°C / min under an inert atmosphere, and keep it at this temperature for 3h , that is, a carbon-coated cobalt sulfide material is obtained.

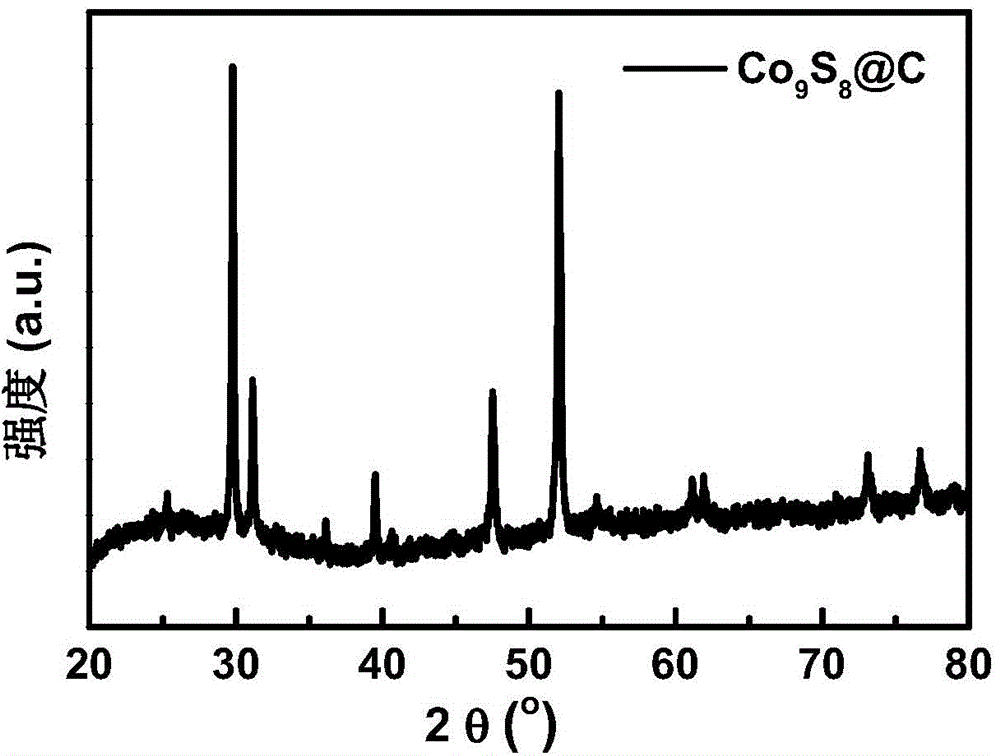

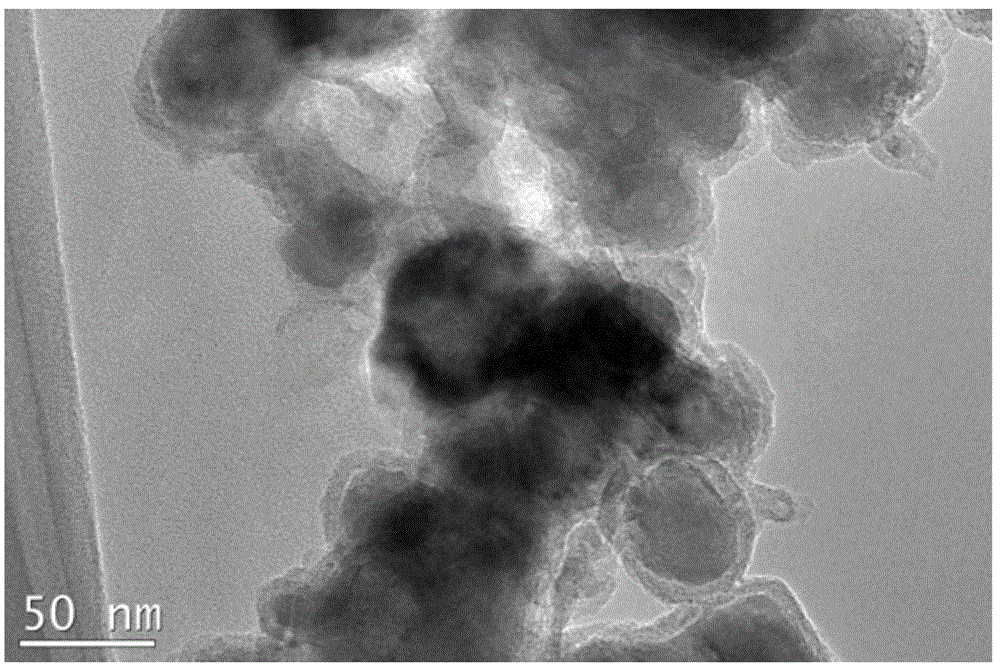

[0026] Some structural studies were carried out on the materials prepared by the above method. figure 1 It is the XRD spectrum of the obtained carbon-coated cobalt sulfide material. The position of the diffraction peak in the spectrum is consistent with PDF#65-6801 (source: International Diffraction Data Center ICDD), indicating that the substance is Co 9 S 8 Material. figure 2 It is the TEM image of the obtained material, it can be seen that the obtained Co 9 S 8 Distributed in the form of nanoparticles (~40nm) in a 5~8nm thick amorphous carbon layer, thus identifying the material as carbon-coated cobalt sulfide.

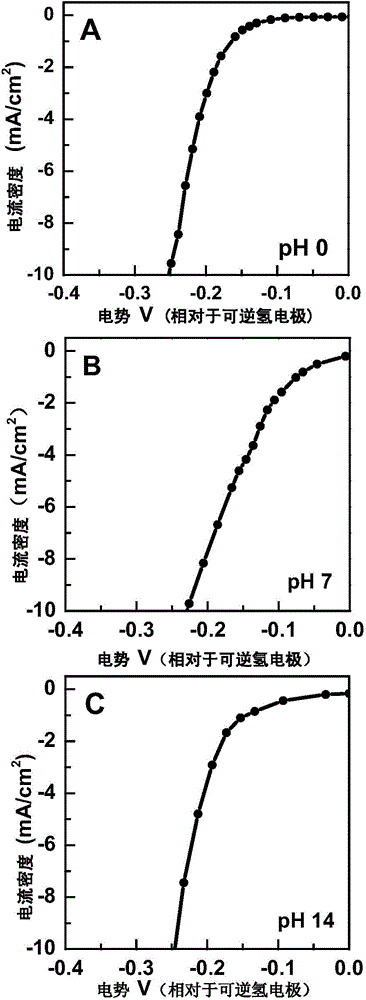

[0027] The carbon-coated cobalt sulfi...

Embodiment 2

[0034] The same as in Example 1, except that the calcination temperature was lowered to 600° C., and a carbon-coated cobalt sulfide material was obtained. The electrocatalytic performance of the obtained material:

[0035]Under the condition of pH 0, when the overpotential is 262mV, the current density of the material reaches 10mA / cm 2 ;

[0036] Under the condition of pH 7, when the overpotential is 240mV, the current density of the material reaches 10mA / cm 2 ;

[0037] Under the condition of pH 14, when the overpotential is 260mV, the current density of the material reaches 10mA / cm 2 .

Embodiment 3

[0039] Same as Example 1, except that the calcination temperature was increased to 800° C. to obtain a carbon-coated cobalt sulfide material. The electrocatalytic performance of the obtained material:

[0040] Under the condition of pH 0, when the overpotential is 268mV, the current density of the material reaches 10mA / cm 2 ;

[0041] Under the condition of pH 7, when the overpotential is 245mV, the current density of the material reaches 10mA / cm 2 ;

[0042] Under the condition of pH 14, when the overpotential is 262mV, the current density of the material reaches 10mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com